No products in the cart.

Packaging Design

Dieline Design Tips & Checklist

Dieline Design Tips & Checklist

Crafting your packaging design around a dieline template allows you to be as creative as you'd like with your packaging while still falling within the specific sizing dimensions of the final packaging product. A dieline clearly outlines all the folding marks, cuts, perforations, and glue lines/fold line of the final packaging design, so there's no surprises when you receive the final product. Think of it like a coloring book: you can incorporate as many colors or designs into the picture as long as you stay within the bold outlines of the book.

At CarePac, we provide design templates and dielines for our customers, but it's not uncommon for them to create our use their own. Regardless of whether you use our dieline or a custom dieline you've created yourself, here are some dieline design tips to help you get started.

Tips for document setup

As discussed on our print ready artwork page, all packaging files should be in CMYK color mode. Our preferred format is Adobe Illustrator (AI) or PDF/X-1a, but other packaging companies may have different preferences. You'll always want to check. You'll also need to make sure the orientation of your dieline is facing the correct way - otherwise the text and images of the final design will be facing the wrong way.

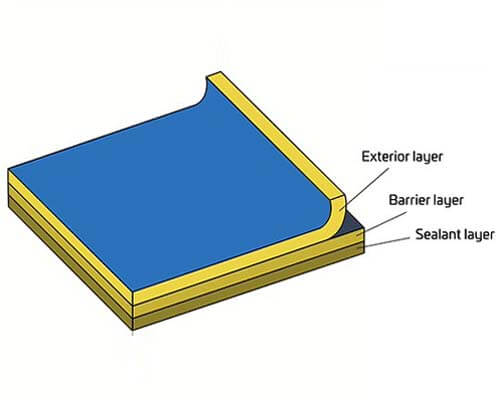

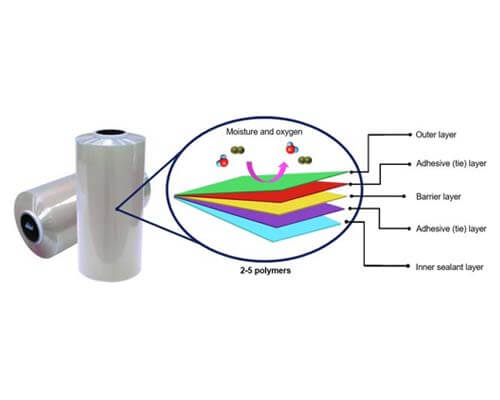

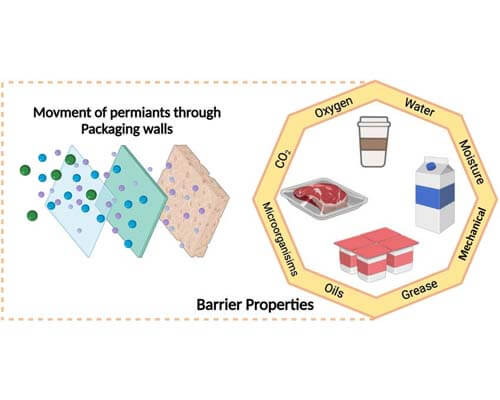

Consider the material

Before using a dieline template, you'll need to nail down the packaging material. Some materials (like cardboard) are very thick and rigid, which has an impact on how it folds and where it can be cut or perforated. While cardboard is quite rigid, plastic will conform to the contents inside. On the other hand, if you overfill the plastic pouch it could be hard to seal. Work with your packaging provider to decide on a material and discuss how the selected materials will impact your dieline design.

Factor in size and weight

Depending on what you're packaging, your packaging should not only fit around your product but protect it from damage during transit and storage. For example, nobody wants to open up a bag of chips only to find that they're all shattered into a million pieces. Consider the size, shape, and fragility of your product when using a dieline template to design your finished product.

Leave space for branding and text

This is the important part: without incorporating company branding or additional text on your dieline, your customer won't know what sets your product apart from all the others on the shelf. Make sure there is enough space on the package to include artwork, information about your business and its values, or allergen information for food products. This is the whole point of a dieline: to show you where you can add text and how it'll look on the final product.

Test and prototype

Before you finalize your dieline design and order 10,000 bags or boxes, you'll want to order prototypes of the bag. This helps you see the bag's functionality, exact size, the logos and graphics, and any labels in person before committing to a large order. This way, if you notice any mistakes with the packaging design you can rectify it before you waste too much money on the packaging. CarePac offers custom prototyping from 100 bags, which is a major differentiating factor from some of our competitors with minimums that exceed 1,000-10,000 bags.

CarePac's dieline design checklist

When designing a dieline, you'll want to follow this dieline checklist to make sure you've covered the basics. As always, our helpful team of designers is here to provide their expertise and help guide you through the process.

[ ] Software and file setup

Start your dieline with a brand new vector file in Adobe Illustrator. Your document should be set to the appropriate size and resolution (typically 300 DPI.) Each packaging provider will have different requirements for dieline design, so make sure to check with them directly before submitting a dieline. One thing all companies have in common, though, is using CMYK document color mode.

[ ] Material consideration

Choose your packaging material wisely. Different materials will impact your dieline design in different ways, so work with your design team and make allowances for the thickness of the desired material in your fold and cut lines. You'll want to make sure that the material you choose (and the design) accounts for the product's protection during storage and transport.

[ ] Product dimensions and weight

Make sure you take the time to measure your product accurately. The packaging design template should accommodate the weight, size, and shape of your product. Not only should you have enough room for your product, but you shouldn't make the top of your bag too crowded. If your package is overstuffed it simply won't function as well as a bag with a little room to spare.

[ ] Branding and information

Yes, your packaging templates should leave room for fold and cut lines, but it should also leave room for branding elements, like labels, custom graphics, your own artwork, images, or a little window that lets customer see the product inside. Consider the best placement for visibility and functionality.

[ ] Prototyping

Creating a physical prototype of your packaging design that you can hold in your hands is essential. It's the only way you can sure that you have the correct layout and that your packaging designer has included everything you need into the design.

[ ] Finalize artwork and design

Once you have a physical prototype in your hands and have confirmed that it follows the proper layout, you'll want to finalize the artwork and design. Add a label, account number, or any other custom feature you need. Check your specifications and submit the packaging templates into production. Your job is done!

Free Dieline Generator

Dielines define the physical size of your pouches. Fill out this form and you'll receive the free dieline by email.

Dieline design FAQs

Here are a few comment questions we receive about dieline design:

How do I know my product will fit in the bag?

The best way to make sure your product fits in the bag is to pay for our awesome prototyping service. With as few as 100 bags, it's a cost efficient way to make sure your product will fit comfortably.

Will retailers accept my size and configuration?

In order to ensure your packaging will be accepted by the retailer, you'll need to check with them directly. You may need a hang hole, and they're the only ones who can confirm if the bag size is correct for distribution.

Does it need to stand up?

Although flat packaging is often the standard, you'll need to decide internally if your dieline should incorporate the need to stand up into it.

Do I have to create my own dieline?

No! CarePac provides design templates, which can be customized to your liking. Because all our packaging is made to order, you have control over the dieline structure and layout.

CarePac: Your partner in dielines and packaging

As you can see, creating packaging isn't always easy. Whether you're packaging food, clothing, coffee, or snacks, our designers can help you incorporate all the necessary elements onto your bag. From images to folded lines, dielines act as a blueprint to your final design and should be taken seriously. Whether you use your own graphic design software or leverage our design team, dielines are the best way to refine packaging so the final product is exactly what you're looking for.