No products in the cart.

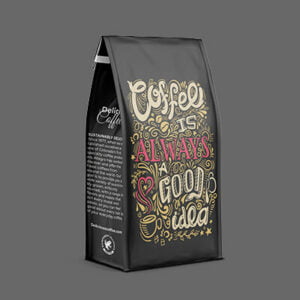

Coffee Packaging

Save Money & Sell More Coffee

Make sure your coffee bag reflects the quality of your product.

Welcome to CarePac. Your new go-to source for your coffee packaging. We offer great prices, and more options than our competitors. And we’ll always let you customize your product.

Like a hungry diner eats with their eyes first… Your customers buy with their eyes before experiencing your tasty coffee. Make sure they like what they see!

Our goal at CarePac is to help you sell more coffee… So we provide total customization of the shape, size, and printing for your packaging. With innovative packaging options like recyclable and compostable bags, to great marketing advancements like digital printing, we’re making custom printed coffee packaging possible for small and medium roasters to compete with the big boys (and girls).

Guide To Choosing Your Brand's Perfect Coffee Packaging Solution

Just like there is a range of different types of coffee beans, roasting styles, and forms coffee is sold in. There are a range of packaging options for coffee, in the ever-developing world of selling coffee. Coffee packaging options include:

- Material Choices: from shelf-life extending to eco-friendly coffee packaging.

- Configurations: Square Bottom, Stand Up Pouches, Filter-Pack Tubing.

- Features: Degassing valves, tin-ties, EZ- zippers.

Most customers come to us knowing what type of configuration, size, and features they want based on factors such as storage conditions, shipping, and the selling environment, and whether the coffee is being packaged for retail or industrial customers. Often our customers want help selecting a printing choice, and quantities they can afford for custom coffee bag. If you are decided on the configuration you want to work with here are some general suggestions and a overview of some of the available options for coffee packaging. Need help determining what to look for in a coffee bag? Give us a call to discuss your brand and packaging needs.

Custom Printed Coffee Bag Configurations

Will you be hand-filling your coffee bags or are you considering automating with coffee packaging tools? If you plan to hand-fill your coffee bags. It is generally recommended that you pick a configuration that has more space in the top to allow you to easily scoop in the coffee.

While hand-packing reduces machinery costs, it drastically reduces your fulfillment quantity, accuracy, and ability to ramp up production. Most modern coffee packaging machines work with multiple bag styles and sizes.

Square Bottom

Coffee Bag

Cadillac of Coffee Pouches

Box Bottom, Square bottom, 8-seal whatever you call them, this is the premium coffee bag bag configurations. Box bottom coffee bag is an elegant and sophisticated format that has been popular for years. It stands independently and offers 5 sides for marketing and branding, and can be used with either a tin-tie or a Pull tab zipper. This gusseted bag style is a popular coffee packaging design due to extra real estate for branding.

Side Gusseted

Coffee Bag

Traditional Design

Side gusseted coffee bags are a traditional option used commonly with mass produced coffee brands. This coffee bag configuration creates that classic brick shape when the top is folded down. Slightly less costly than the flat bottom coffee packaging configuration, it is compatible with Tin-tie closures Gusseted sides provide room for more coffee and sits great on a shelf just like our other stand up coffee pouches.

Stand Up

Coffee Pouches

Economical Choice

Stand up pouches for coffee are a “new school” design. They are more economical than the other two configurations and offer several advantages. First it can stand independently, and has become a familiar shape to most consumers, but it also allows for the use a pull tab zipper making it easy to fill. The zipper also allows the consumer to maintain freshness. While it is still a less common format it has become more popular due to it's reduced costs.

Coffee Filter Pack Tubing

Coffee Filter pack tubing, Stick packs or flat bags are for single serve coffee sales. We can make this type of packaging a couple of different ways, either as flow tubing, or coffee filter pack pouches. Tubing is only used if you have a form and fill machine. pre-made stick packs and Lay Flats are for non-high speed filling. This packaging is perfect for sample size coffee bags.

Coffee Packaging Re-Closure Options

With multiple re-closable zipper options we can make sure your coffee is built with the proper zipper option. Quality re-closable zippers help maintain freshness during consumption. These re-closable options can be employed either independently or together in your coffee bean packaging. Bags from CarePac are great for ground coffee, whole bean, roasted coffee or green coffee. We work with coffee shops, coffee roasters, and companies large and small. Give us a call to learn how we can help. Our flexible lead-time keep you in control.

Tin Tie

Classic Tin Tie closures are still very popular. Tin Tie's can be combined with Easy-Peelable interior liners, or the pouch can be lightly heat sealed and combined with a adhesive tape. Pouches stay closed after the coffee is opened by rolling down the bag and pinching each side shut. A great style choice to lock in natural flavors.

Pull Tab / EZ-Pull

Pull tab closures are popular because they make loading the pouch easier, and help mainatin the freshness of the coffee loner than tin-ties. It works well on fat bottom coffee bags and stand up coffee bags. This is the most popular enclosure style for smaller roasters. No longer do you have to deal with tin-ties falling off, or applying them.

De-Gassing Valve

The ubiquitous one-way degassing valve can be placed high or low on the pouch. If you are packaging a single style of coffee, like ground or whole bean specific valves can be applied to your pouch. Alternative, we have a mult-use valve if you are packing both styles. This style of one-way valve allows gasses to escape without letting oxygen in.

Best Prices on Custom Printed Coffee Bags

Flexible options to reduce your costs! You know that coffee bags come in all types of shapes, sizes and colors. How? we offer digital and plate printing options for your custom printed coffee packaging to let even the smallest of roasters compete with the big coffee beans on the block.

That means prices that work for you… With your choice of production time based on our three options. The price of our pouches is determined by a couple of factors. Quantity, material, lead-time, coffee bag configuration, and more. This list gives you a rough estimate for common sizes and configurations.

Start-Up Roasters

Small quantities with fast turn arounds for start-ups ready to take it to the next level!

Coffee Bag Size | Price Range |

|---|---|

12 OZ Side Gusset | $1.25 - $0.50 |

12 OZ Box Bottom | $2.00 - $0.55 |

Established Roasters

With full production runs of 5,000 + bags, a lot more options open up. Your individual project may vary depending on your choices of material, configuration, lead-time option.

Coffee Bag Size | Price Range |

|---|---|

12 OZ Box Bottom | $0.55 - $0.40 |

12 OZ Side Gusset | $0.50 - $0.30 |

Building Great Coffee Packaging

Starts with the Material

CareSilver

CareSilver is a great solution for coffee pouches. CareSilver Vapor Metalized PET film is strong, and provides a sufficient barrier for coffee beans and ground coffee, offering a great price point as well!

Eco-Friendly Coffee Bag Material Options

Carepac also stands out thanks to its eco-friendly custom packaging options that include both recyclable and compostable solutions. No more surfing the internet to find the right fit for you and the planet… We offer top-shelf printed flexible packaging solutions for coffee roast brands of all sizes. With this addition alone… You can charge a premium price, increase your brand recognition, and improve your product shelf life… All while playing your part in saving the planet.

CareCompost is a compostable film for coffee pouches. we offer several compostable film options, to choose from. between.

CareRecycle recyclable and PCR materials are gaining in popularity as an alternative to more expensive compostable options.

Printing For Your Coffee Bags

We offer digital printing with custom sizing. Unlike competitors, we don’t limit you to a few set sizes, and configurations for your custom coffee bags. With digital printing we can print multiple variations of your coffee packaging, so even roasts that you don’t sell a lot of can have their own design and images.

Customers who are ready to print more than 5,000 units can also explore our plate printing options to print their coffee bags with their own customized art work. Plate printing yields a lower per-unit cost, but may result in higher setup costs. Printing your coffee packaging, helps increase the image of your brand, and gives a great first impression when your customer is perusing the coffee aisle. With both digital and plate custom printing you also have more real estate to spread your brand identity because you’re not limited to a small label. Also, buying custom printed bags saves your employees time from having to label individual bags.

Trends in the Coffee Industry

Customers buy with their eyes. Make sure your packaging reflects the quality of your product.

As grocery stores reconfigure their shelving, it leaves certain products above or below the coveted eye-level area. In order to catch the eyes of your target consumer, your coffee bag design and packaging quality become more important than ever. Just look at some of the top coffee roasters and the emphasis that they put into ensuring that their coffee bag stands out among the rest. When it comes to coffee packaging, customers purchase with their eyes first. That's why it's more important than ever to ensure you're up to date with the recent trends in the coffee packaging industry. That way, your brand has a higher chance of standing out above the crowd and getting noticed.

CarePac works with many coffee clients who are fighting for that eye-level area by changing their art, bag configuration and approximate volumes for whole bean and ground coffee. Contact us today to see how we can help you with custom coffee bags that will take your coffee business to the next level.

New to Custom Coffee Packaging?

Check out our process below and then get an quick quote.

Step 1:

Develop Your Art

Step 2:

Sizing and Configuration

Step 3:

Master Art Proofs

Step 4:

Bag Production

Step 5:

Sell More Coffee

Step 1: Pick A Material

Bring us what you have, and we'll work with it. Some customers have already spent a lot of time (and money) developing an entire branded coffee pouch design. Others come to us with the logo they've been using, and a sketch on a napkin. Where ever you are in your coffee packaging journey, we can work with you to get a design layout that is on-brand and ready for retail. With more than 10 years experience, we will walk you through every step of the process to ensure your bag will fly off the shelf.

To get started use our quick quote form, or feel free to give us a call. We’re happy to help.

Step 1: Instant Online Quote

Every custom bag we print goes through a very specific set of steps, from choosing your bag size, material and configurations, to proofing, to final delivery. With more than 10 years experience, we will walk you through every step of the process to ensure your bag will fly off the shelf.

We make it easy for you to get an instant online estimate using our bag calculator. Choose how many bags you want, how soon you need them, what type of bag you want and what features you want. Get a free instant price quote today!

Or feel free to give us a call. We’re happy to help.

Step 2: Sizing and Configuration

Pick the exact right size custom printed pouches for your product. All custom printed pouches that we sell can be custom sized, with custom die-cut windows, or other unique configurations. Generally if it is possible with a flexible material then we can supply your custom printed pouches, not a problem.

Because printing occurs before the bag or pouch is made, (we print the roll stock), sizing and configuration is totally customizable to your specifications. You can customize the size of your package to exactly what you need.

Step 3: Master Art Proofs

You don’t have to bring press ready art. There are many technical considerations when printing barrier films, and we do all that work for you. We’ll take your original art files and set them up for printing to ensure you get the best quality printing, and develop digital art proofs that you can revise. We focus on providing custom printed pouches and barrier packaging that meets your budget.

Step 4: Material Is Printed

We offer Digital, Plate, and cylinder printing options for making your custom printed pouches. So once the material rolls are cut, treated, they are then printed, and finally any lamination is applied (matte, gloss etc).

Step 5: The Bags Are Made!

The printed material is then made into your bag.We offer a selection of finishing laminations, and varnishes for your custom printed pouches.

Coffee Packaging FAQs

Whether you are new to custom printed packaging or a seasoned pro you may have a few questions about our products and process.

Q: Do you offer wholesale pricing?

Yes, with CarePac you can save even more with our everyday, wholesale pricing available on our coffee packaging. Production quantity orders start at 5,000 bags, while prototyping, and test runs can be accomplished with smaller orders.

Q: Do you offer custom sized coffee packaging?

Looking for custom sized bag? We’ve got you covered – that is why we offer custom-sized pouches and bags to meet these needs. We make it fast and easy. You can even use your artwork and designs.

Q: Can I print my own design on my coffee packaging?

Depending on your needs and preference, we offer custom printing both digitally and with the use of plates. While digitally printed bags come with several advantages, we sometimes advise clients to opt for plate printing depending on their needs. Mostly because plates offer the lowest per-bag price points. However, digital prints offer a more robust color count and are best for short run usage. Whichever the case, we always have a support staff to walk you through the production process and help you identify which printing is best for your coffee product.

Q: What if I need help designing my coffee packaging?

You don’t have to bring press-ready art. There are many technical considerations when printing barrier films, and we do all that work for you. We’ll take your original art files and set them up for printing to ensure you get the best quality printing and develop digital art proofs that you can revise. We focus on providing custom printed pouches and barrier packaging that meets your budget.

Q: Is it safe to add a clear window on coffee packaging?

Adding clear window it typically avoided to review UV exposure to the coffee. But some roasters do offer a window to stand out from the competition. We typically would not recommend it

Q: What is the standard lead time on a custom printed coffee bag?

In our industry, contrary to what you might think, ten-week lead time is not uncommon. We offer the best lead-time options on all our quotes compared to other brands. Our lead time list for custom packaging offers you several options, from super fast digital printing in as little as 15 working days. Since everything we do is made-to-order, the more time we have to plan out material, machine time, and prevent change over waste, the more savings we can pass on to you!

Q: How much does a custom printed coffee bag cost?

There is a pricing table on this page that gives some rough pricing, but it's easy to get a quote, check out quick quote form to get a cost for your bags.

Q: How low is the Minimum Quantity Order for printed coffee bags?

Small digital orders can be produced from a few hundred bag. This is best for testing, and prototyping. If you're a roaster selling coffee on a on-going basis, production quantity orders start at 5000 bags.

Q: Do you offer tin tie coffee bags?

Yes, we do offer tin tie coffee bags that many customers have come to expect. CarePac has lots of options for coffee packaging.

Q: Are your coffee bags smell proof?

Yes, all are products are smell proof bags from stock bags to custom bags. We make it sure that it feature smell proof bags especially with coffee packaging.

Q: Can I use biodegradable coffee packaging?

First, a good coffee packaging bag is built from the right materials, compostable and biodegradable materials have become very popular, but won’t have the same self life potential of more traditional materials that offer a more active barrier against moisture, dust, ultraviolet rays, and a variety of other environmental factors that can affect the quality of your coffee.