No products in the cart.

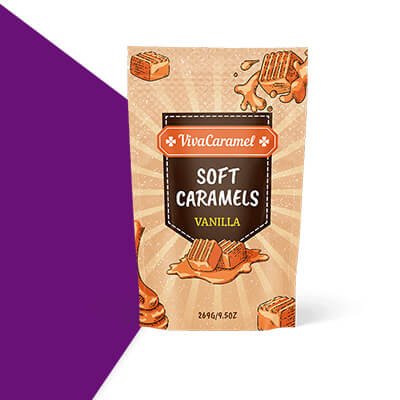

Custom Candy Packaging

You want to sell more candy? Get

Custom Printed Candy Bags!

Take your custom candy bags to the next level with an economical and printed pouch with your company's logo. CarePac provides flexible candy packaging in a variety of different formats and finishes that can be customized with your company's artwork.

In a crowded market where candy is very popular, you want your product to stand out on store shelves. The customer eats with their eyes, and the better looking your product is on the shelf the more they are enticed to purchase.

We think of candy as being a product which is fairly shelf stable, but even candy can get tasteless and delay when not properly packaged. Also, depending on the serving size, customers may not consume the entire product in one sitting. By using higher barrier materials you can extend the shelf life of your product, and by offering a zipper in your custom printed candy packaging, you give customers the flexibility to store sweets and ensure that candy lasts beyond a few weeks.

CarePac Advantage

Take your custom candy bags to the next level with an economical and printed pouch with your company's logo. CarePac provides flexible candy packaging in a variety of different formats and finishes that can be customized with your company's artwork.

In a crowded market where candy is very popular, you want your product to stand out on store shelves. The customer eats with their eyes, and the better looking your product is on the shelf the more they are enticed to purchase..

Save Money

Custom printed candy packaging in a flexible bag reduces costs over more expensive options like paperboard boxes.

Full Color Printing

Print any logos graphics, and nutritional information on your candy packaging is easy with CarePac's dual option of Digital or Plate printing.

Advanced Finishes

Choose advanced pouch finishes such as metalized, holographic, and spot matte / spot gloss finishes.

Maintain

Freshness

High Barrier materials keep the sweets in custom printed candy packaging fresh for much longer than traditional sweet packaging, extending shelf life!

Sell More

Candy

Customers enjoy the benefits of candy bag re-closable zippers + the stand-up pouch with your custom printed design helps your candy package stand out on the shelf.

Low Minimum Order Quantities

Full Production runs of printed and customize pouches start at 5,000 custom candy bags. We offer prototyping and smaller digital runs as well, so we can start your brand at lowest quantity you need.

Custom Sized Candy Packaging

When we say custom, we mean it. With CarePac you can customize all features and sizing from basic things like width, height, and gusset size, to more advanced features like bag finishes, zipper location, and hang hole size. Customizing your printed candy pouch ensures you get exactly the right pouch for your product.

Best Configurations for Custom Candy Bags

Here are some of the configurations for custom printed candy packaging we recommend

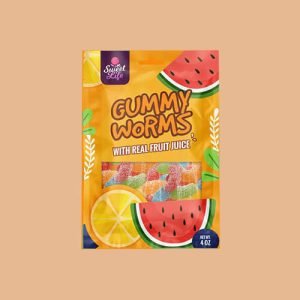

Lay Flat Pouches 2-seal and 3-seal

The design and shape of three-seal bags allow for a stylish take on stand up packaging, with the strength and durability needed for bulk-sized candy quantities. It is a intermediate cost point and allows for peg board display.

3 side seal pouches are a fantastic choice when you do not need the product to sit on a shelf. Candy, herbs, and jerky are just a few examples where this would be a viable configuration.

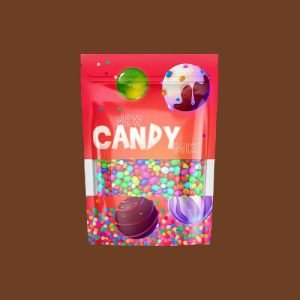

Reclosable Zipper Pouch Bags

These are indispensable for any candy. Custom printed candy packaing that can be easily sealed again by customers helps their products be fresh. Adding a reclosable zipper gives your customers the ability to practice portion control or enjoy their snack on-the-go. This is designed for higher margin candies.

Fin-Seal Pouch

Fin Seal pouches are a form fill design and is used in certain fill machines. It is available both as a finished pouch and a fin seal tubing ready configuration. Fin Seal pouches are a traditional pouch design that has been used successfully for years in candy packaging designs.

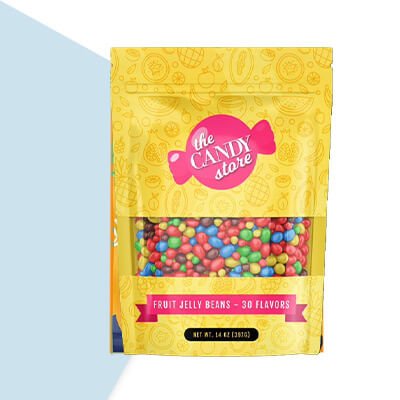

Stand Up Pouch

Stand Up Pouches are one of our customer’s most popular bag configuration is the stand up pouch. The name says it all, as these bags are outfitted with a bottom gusset, that when deployed, allows the pouch to “stand up” on a shelf in a store. Great for candies like gummy candy.

Choosing the Right Material for

our Custom Candy Bags

The first thing you should do when determining your wholesale candy packaging budget is to understand your market position:

- What Location: Gas Station vs. Whole Foods?

- What Lifestyle: Organic v. Mass appeal?

- What Longevity: Shelf Life or Grab and go?

If you are trying to hit very tight margins, we would recommend BOPP, thin films, and plate printed, no feature bags or roll stock for your FFS machines. Alternatively, if you have a higher end product, that needs to stay on the shelf for a longer period, we would move into more substantive barriers like our CareFoil or CareSilver material, full color printing and add features to the pouch.

Picking the Right Bag for

Your Candy Packaging

Consumers generally store candy in the pantry on the shelf. Candies generally require less barrier than some other products because of their sugar content.

Taffy, Caramel, Nougats

These candies should be individually wrapped to reduce clumping, and allow your customer to pick them out individually to eat. Clear cellophane or printed roll stock is a great choice for the candy packaging design for these sweet treats such as cookies. Especially if you're looking to show off each delectable flavor, you'll need individual wrapping to do so.

Moist Candies

Do not mix candies that absorb moisture such as caramels, mints and hard candies with candies that lose moisture such as fudge and creamy candies. While the barrier of your outer custom printed candy packaging will prevent the moisture from getting out of the bag, the moisture will migrate between the candies. Storing these sweets in the same container will cause the harder candies to become sticky. To make sure that hard candies stay hard, sprinkle with finely ground sugar and store in an air-tight jar.

Chocolate Candies

Chocolate is made from cocoa beans, the dried and fermented seeds of the cacao tree. Chocolate is not actually candy, but a lot of people refer to it as such. Now many chocolate candy flavor exist surely consumer enjoy such as chocolate mints, dark, milk, chocolate caramel and more. Make personalized candy bags for your chocolate candies to stand out the best way you can offer to your customer.

As a wedding favor or as gift bags, our pouches are perfect for storing your chocolate goodies!

Candy Packaging FAQs

Whether you are new to custom printed candy packaging or a seasoned pro you may have a few questions about our products and process.

Q: What type of candy can I package with your pouches?

The sky's the limit! We’ve done pouches for all kinds of candy from hard candy, gummies, chocolate covered pretzels, candy canes, chocolate, caramels, you name it, we can pouch it.

Q: Can I do a pouch with a place to see the candy?

Yes, that is known as a “window.” Simply lay it out in your art file. Windows are commonly shaded light grey or blue to call them out.

Q: I want my pouch to hold 4 ounces of my candy. What size should I use?

This is tricky as different candies are different volumes. We recommend using pouch dimensions (width x length x gusset). You can order samples here, or if there’s someone in your market with a perfectly sized pouch, break out the measuring tape and let’s use those.

Q: Loading and sealing the bags is taking a lot of time. Any ideas?

If you’re using a three seal flat pouch, we recommend switching to what’s known as a “bottom fill configuration” that means everything is nicely sealed at the top and you put the candy through the bottom and heat seal there. It saves a lot of time.

Q: Can I print on both sides of the pouch?

Yes, of course. Our candy clients often have nutritional information, UPC codes and ingredients on the back of the pouch. You can even print on the bottom of a stand up pouch, that’s another spot for a UPC code or web address.