No products in the cart.

Packaging Inventory Management: How to Manage a Packaging Inventory System

How many months of packaging inventory should you carry?

That is a concern for almost any business because inventory ties up money but running out of inventory can mean lost sales—especially if getting a large order is contingent on rush delivery.

In the start-up phase of your business, figuring out your packaging inventory management is tough. There are plenty of formulas for calculating packaging inventory, plenty of rules about weeding out stale inventory, but using those inventory management formulas depends upon experience--a track record. And a track record, especially with warehouse operations and inventory tracking, is what your start-up does not have, as yet. And, if you are like most starting businesses, there is too much to do with too little money, so you don't want to solve the inventory problem by "being on the safe side" (that is, overstocking raw material).

Inventory management basics

These are a few of the basic often cited for getting a handle on inventory:

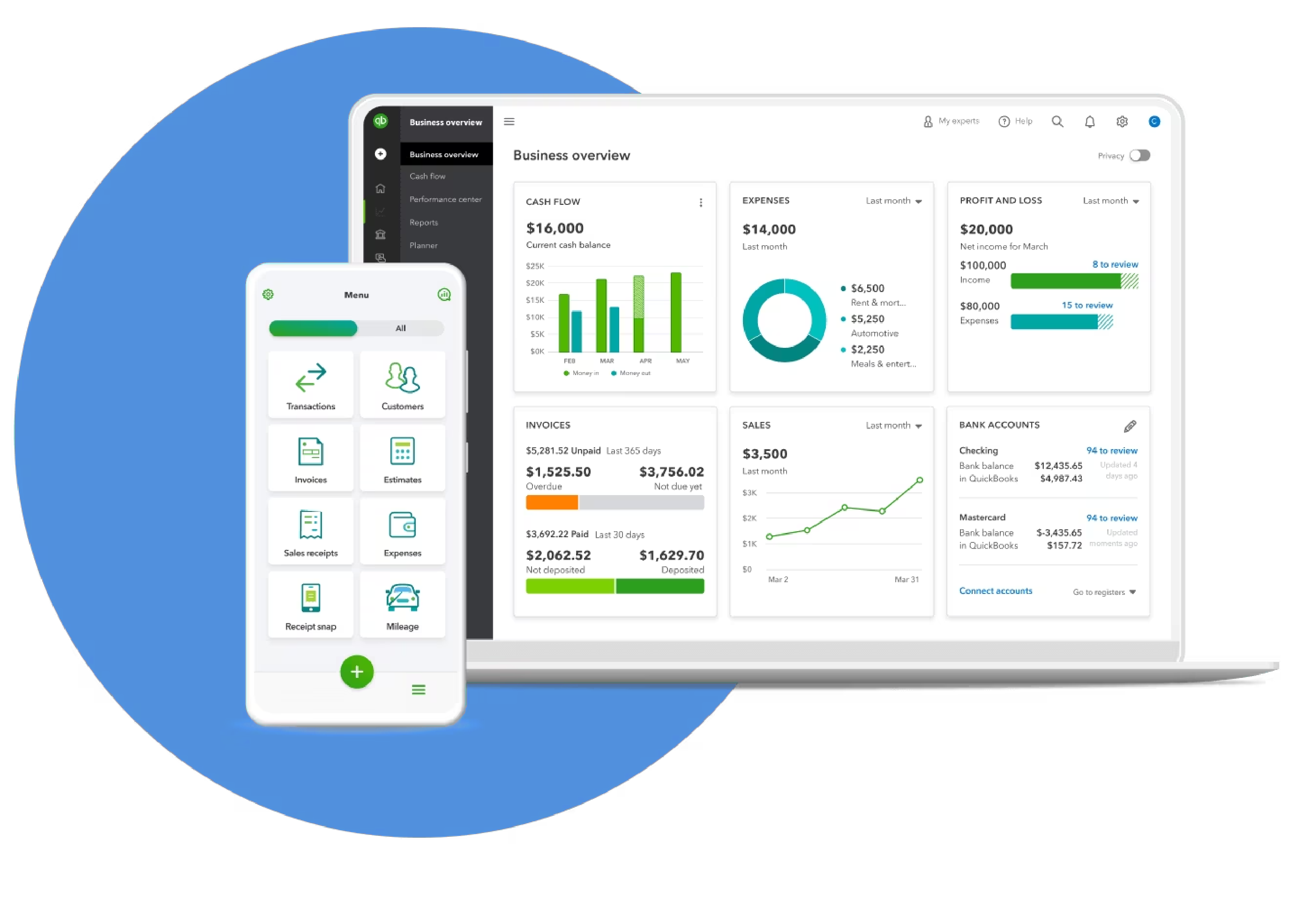

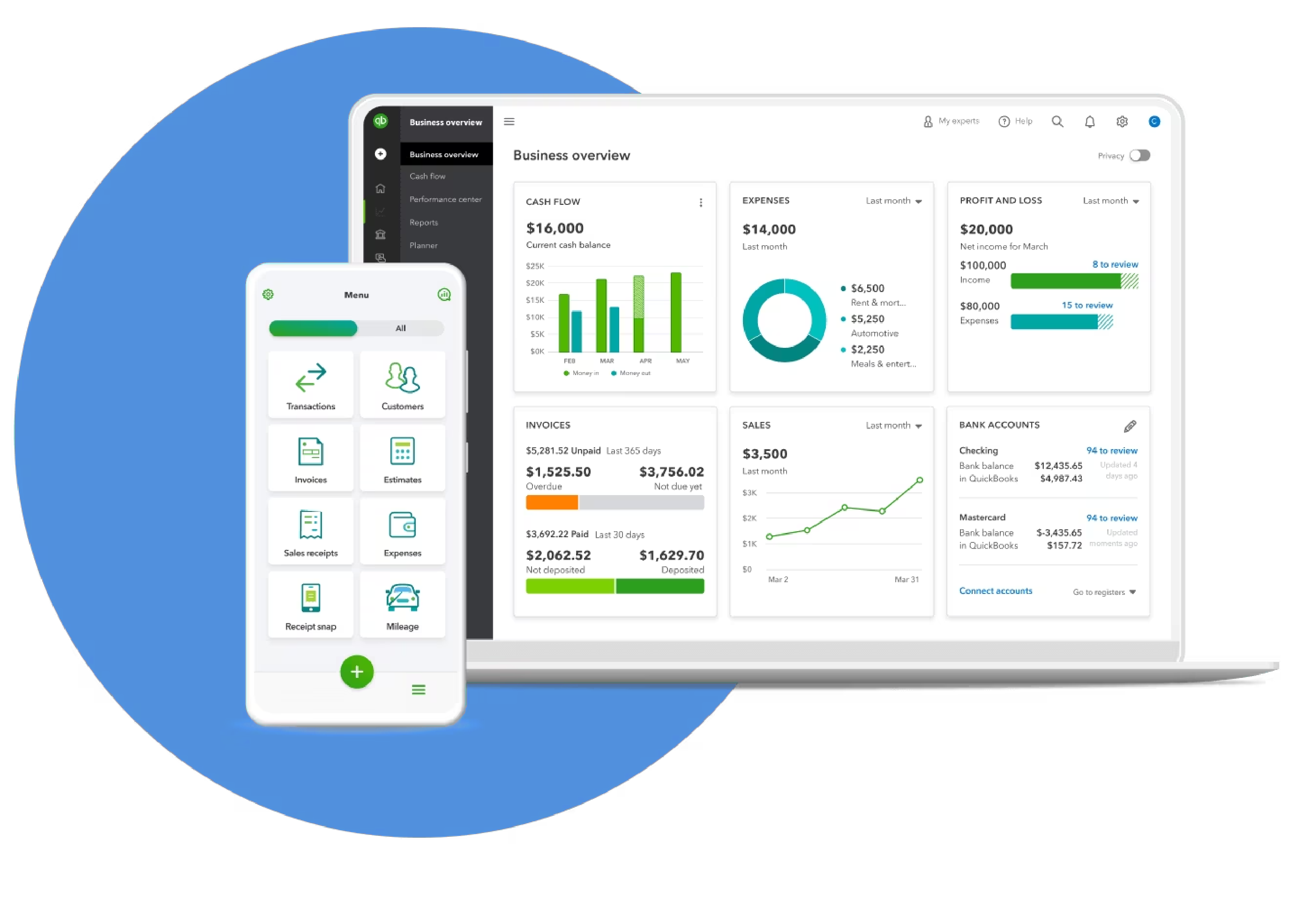

Use QuickBooks to manage vendor invoices and supply

Use an inventory-tracking system with software suitable to the size of your business. One of the best-known management systems is QuickBooks, but there are many others. Your accountant can give you a hand here. There are inventory systems designed for small businesses. You and others in the company should become expert in using whatever system you choose.

Fine-tune your managed inventory

You will want to fine-tune your forecasting once you have a track record. This way you never have too many corrugated boxes, and your vendors aren't sending you an oversupply of products.

Brush up on packaging engineering terminology

There are standard measures such as "identify low-turnover stock." The so-called Pareto principle says that about 80 percent of your sales will come from 20 percent of your sales items. That is something you can learn, and use, when you have more experience.

Track inventory systems in real-time

Today, you can quite easily track your stock in real-time with software that registers incoming inventory and sales. When this system is providing the required feedback, you can make orders for resupply automatic when inventory sells down to a certain point.

Slash the lead-time for your boxes

Slashing supplier lead-time, as we discuss, means that you can purchase new inventory closer to the time that you actually need it. But be sure that your supplier can deliver according to the promised schedule.

But keep in mind that whatever handle you get on ordinary inventory needs, the arrival of the holiday season probably demands a different plan and different calculations. Many businesses do a surprisingly large percentage of their entire annual business in the weeks around the holidays. To be caught short of inventory then presents a double dilemma. You can't sell what you don't have and your suppliers are under pressure during the holiday season just as you are.

Your packaging inventory

At Carepac, where our business is designing and manufacturing bags, we see new firms struggling with these problems all the time. If your product requires packaging—then, no packaging, no sales. What is more, designing the right package not only protects the quality of your product (freshness, protection from moisture); the right package is pivotal to good marketing and especially the "point of sale" appeal of your product.

As a start-up, simply do your best at budgeting and forecasting, but you can do it better with help from your accounting, marketing, and sales colleagues. Given your financial expectations for the first month, six months, and year, how many bags will you have to sell? Your business may not have a track-record, as yet, but other businesses of similar size with similar products in your market do have experience that you can extrapolate to your situation. There are local organizations such as your Chamber of Commerce and literally hundreds of online groups where small businesses of every kind, in every field, regularly exchange information and hash out problems they all face together.

Also, your salesmen and advertising consultants probably have goals. Are they approaching potential buyers for large orders? What do they see as the prospects? And, if you get those accounts, will you face a long lead-time in delivering because your packaging is not ready?

Warehouse lead time

Lead-time also can be significant in other ways. If possible, when ordering your bags or other inventory, you want to avoid a premium charge for rush jobs. Most suppliers, and certainly Carepac, have a backlog to fill in the order received. Make no mistake, the supplier wants your business. At Carepac, we make every effort to accommodate deadlines on orders; but we also want to be fair to our current customers.

Let our highly experienced professionals discuss with you a lead-time for ordering that is neither unnecessarily long nor unrealistically short. We take packaging seriously, of course, as should you, and we advise an early consultation to leave time for innovative design that speaks to meeting your distinctive needs, care in manufacturing and quality control, shipping, and any changes you might want to discuss when you receive your order. We are there at every step in the process and when you get in touch, you talk with a real person at any time you wish. We reserve email, online chat, and other avenues of communication for more routine matters.

The consultation is free, the online price estimate is free, and we are ready to talk whenever you are ready. The challenge of supply chains and controlling inventory for the lowest cost and greatest sales effectiveness never changes—but how you choose to deal with the challenge certainly can change. We want to discuss how we can help in your own stage of business development from start-up to maximal growth.

Getting in touch with Carepac

Your first step is to reach out to Carepac for a wealth of information on every aspect of packaging, for your free estimate, and for consultation with our specialists on all phases of producing the right packaging for your product—and getting it to you when you need it.

Contact us now!

And be sure to check back here regularly for information, insights, and updates on these and many more issues.

For a quick daily "hello" and update, follow us on Twitter for new offers, reports on new developments in the field, and tip about conditions affecting the challenges we both face.

Tags