Subtotal: $0.00

Food Packaging Design

CarePac’s Guide

to Food Packaging Design - Designing Food Packaging

The phrase “don’t judge a book by its cover” doesn't apply in the world of flexible food packaging. Technology has made it easier than ever to capitalize on your new idea and build a brand, but just because the product is great, doesn’t mean that your packaging design is.

New innovations in flexible packaging and pouches allow for even more opportunities to establish a unique brand identity with your packaging design. If you’re just “enclosing” your product, you’re missing a crucial opportunity to tell your brand's story and build a lasting visual identity with a unique food packaging design.

So what is the first interaction you want to have with your customer? How will you differentiate your packaging and grab consumer's attention in a crowded market, and communicate the value of your product at first glance? If you don’t know the first thing about design or packaging, don’t worry, we’ve got you covered.

In this blog, you'll learn how to increase sales, encourage repeat purchases, attract attention, and create a strong brand identity through your product packaging design.

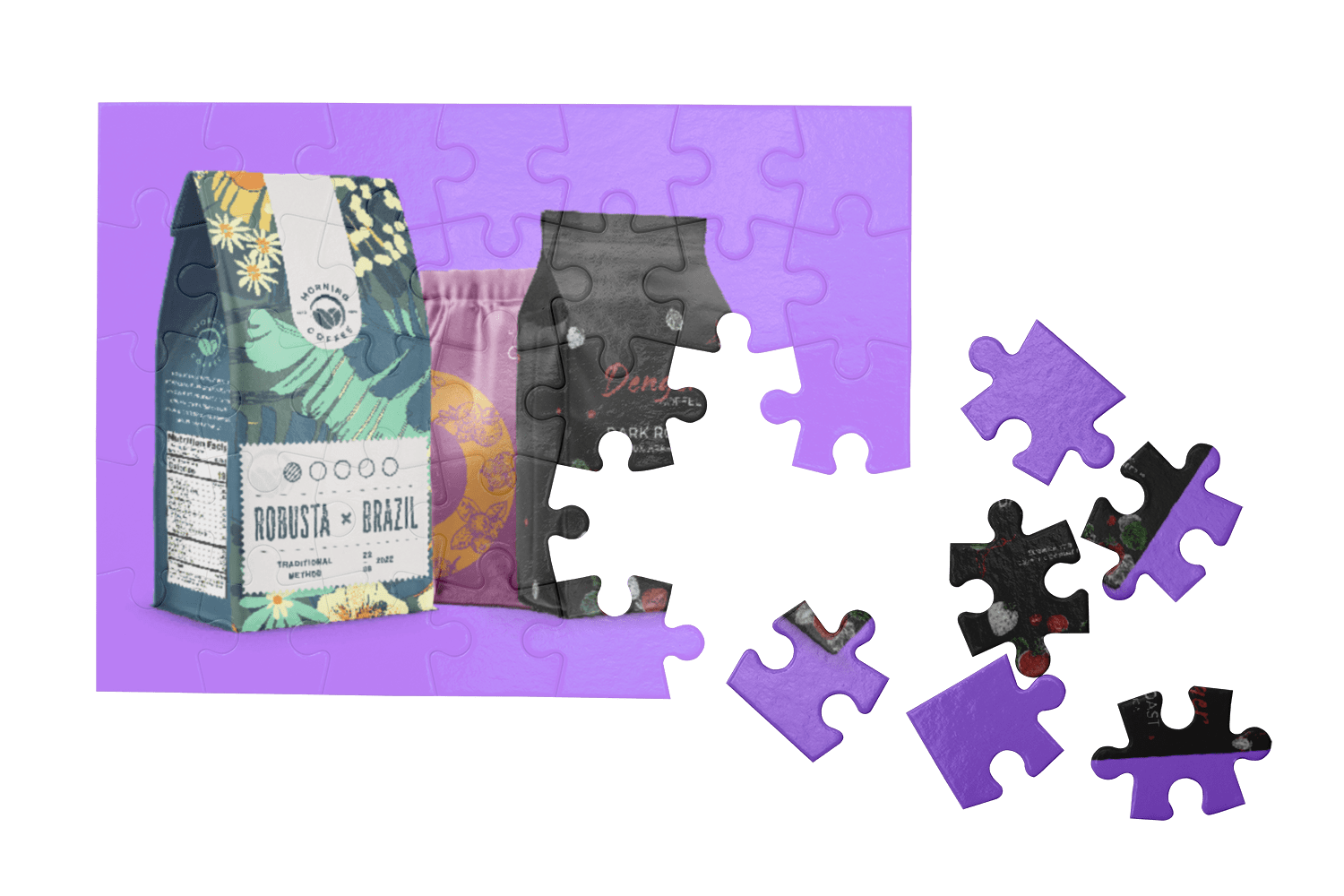

#1. Food Packaging Design & Brand Strategy

The most iconic brands in the world leave an imprint on you.

And the product is only one piece in a larger brand strategy puzzle.

How is the experience of your product different from other brands? What are the stories, emotions, and narratives that you want your customer to connect with?

It doesn’t matter if sustainability, luxury, or affordability, is your primary identity, the same rules of cohesive branding and product packaging still apply in a consumer's mind.

A brand promoting local tribal artisans, for example, might incorporate indigenous art into its designs or packaging. A brand that focuses on organic produce may want to tell potential customers or their target market about how they source their food products.

A luxury brand will have a more sophisticated and exclusive brand voice. They may want to talk about their different flavors, safety concerns, their use of natural ingredients, environmentally friendly packaging, or anything else their ideal customer may be concerned with.

But brand strategy goes beyond visually appealing packaging and a focus on sustainable materials; think about that first experience your customer has with your product. What emotions do you want them to feel? What type of materials and details can you add for a truly unique brand experience in the grocery store?

#2. Finding The Target Audience of Your Product

If you try to sell to everyone, you sell to no one.

In order for your brand to be successful, it needs to speak to a specific customer avatar.

Is your product for kids or teens? Men, women, or both? Now go deeper. The more layers you can pull back, the easier it will be to market and sell your product. Does your product packaging need to be aesthetically pleasing and forward thinking, or should the label design use bold colors in its unique design?

Let’s look at a quick example.

Are you selling beef jerky to younger men who live an rural lifestyle?

Or are you selling beef jerky to 22-35 year old men who spend a majority of their time developing self-sufficiency skills and exploring the outdoors with their dog?

See the difference? Your brand's identity should be specific. Otherwise, your talented designers won't know which key element to incorporate into their great packaging.

The latter gives us a much better idea of our ideal target audience.

From here, we can imagine the type of media they consume, where they shop, and what other products they might buy. And we can begin to explore durable product packaging options that will correspond to their lifestyle.

Imagine the ideal person that you’d like to sell to, and create a detailed list of their traits, interests, and demographics. If they share the same values, this is a great example of something you'd want to incorporate into your great food packaging design.

#3. Packaging Design:

Analyzing Competition and Listening to Consumers

In order to know what you may need to change about your food package design,

you need to have an eye on your competition and their brand identity.

Competitive Analysis: The first step in understanding the market and your brand identity is to identify both direct and indirect competitors in the food industry. Gather physical or digital samples of competitor product packaging and pouches and analyze designs, size, information provided, material used, information about their packaging label, and the overall ease of use with their packaging. Look for things you like, things you might change, and opportunities to be different when you create packaging for your own product.

Consumer Feedback: If you have an amazing product, incorporating this into your product packaging should be one of your major goals. You need functional, aesthetic, durable, and effective food packaging design. And the best way to find out what customers like, is to go directly to them. There are numerous social listening tools that allow you to gauge real-time feedback on competitors' packaging. Direct from the consumer insights provide a clear picture on market trends and consumer frustrations and needs.

#4. Product Packaging –

How To Make An Impression On Consumers

Consumer Experience: Flexible, textured, and unique packaging materials, turn the mundane act of opening your product package into an experience. It can create polarity and give your brand an immediate “wow” factor. The package is the first physical experience your customer will have with your brand, so why not make it special? In the internet age, small details or adding a new spin on an old packaging concept, can bring an element of virality to your brand. It shows your customer that care and attention to detail aren’t just reserved for the product itself.

Think of resealable pouches for portion control or transparent sections to tease your product. The only limit is your imagination.

Food Packaging Shelf-Presence: It’s important to develop collaborative relationships with retailers to ensure you know where your product will be physically placed. For example, if your product is being placed on a grocery aisle end cap rather than a bottom shelf, you may want to change certain design elements or materials. For flexible food packaging pouches, controlling for light, moisture, and oxygen is crucial to ensure a fresh product.

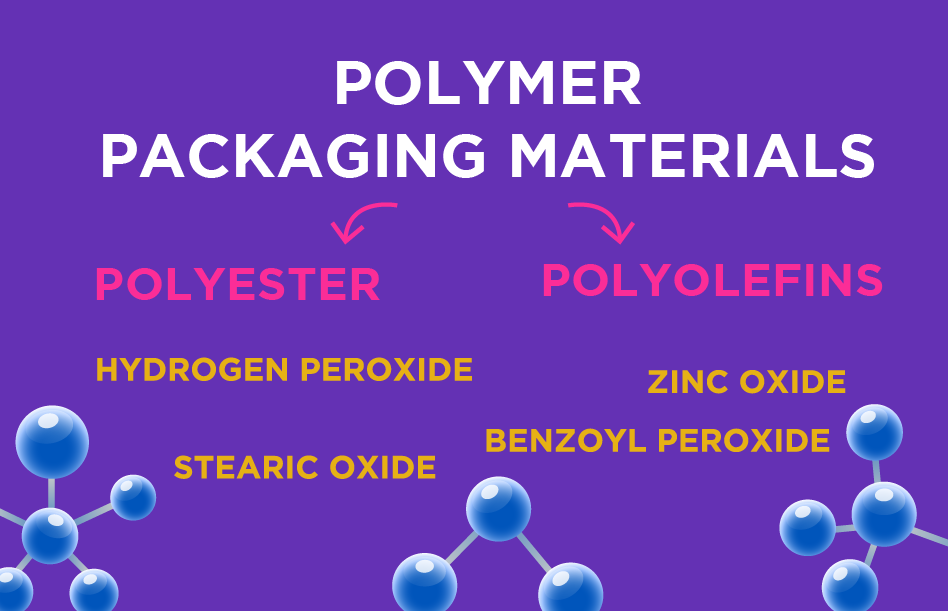

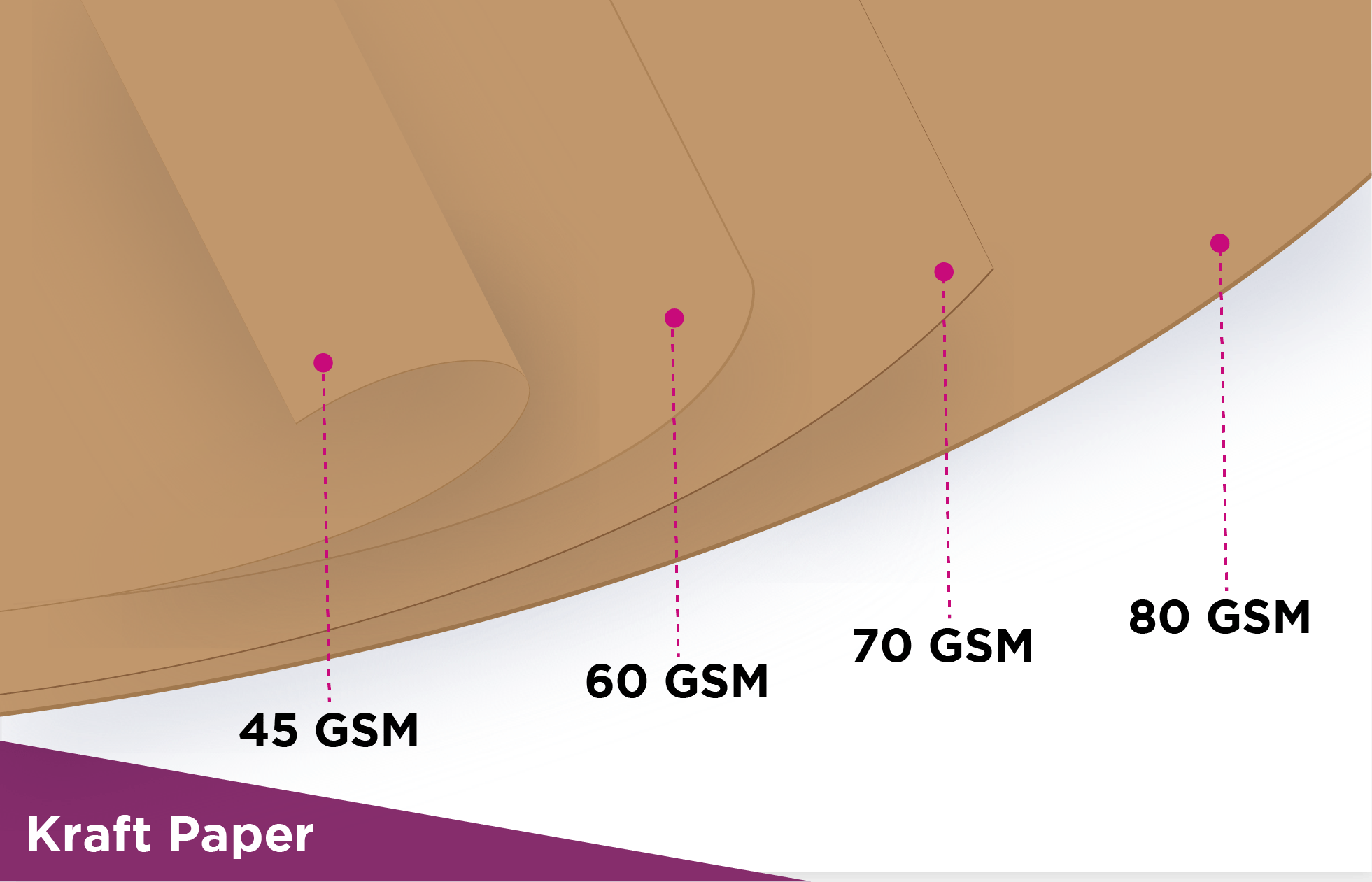

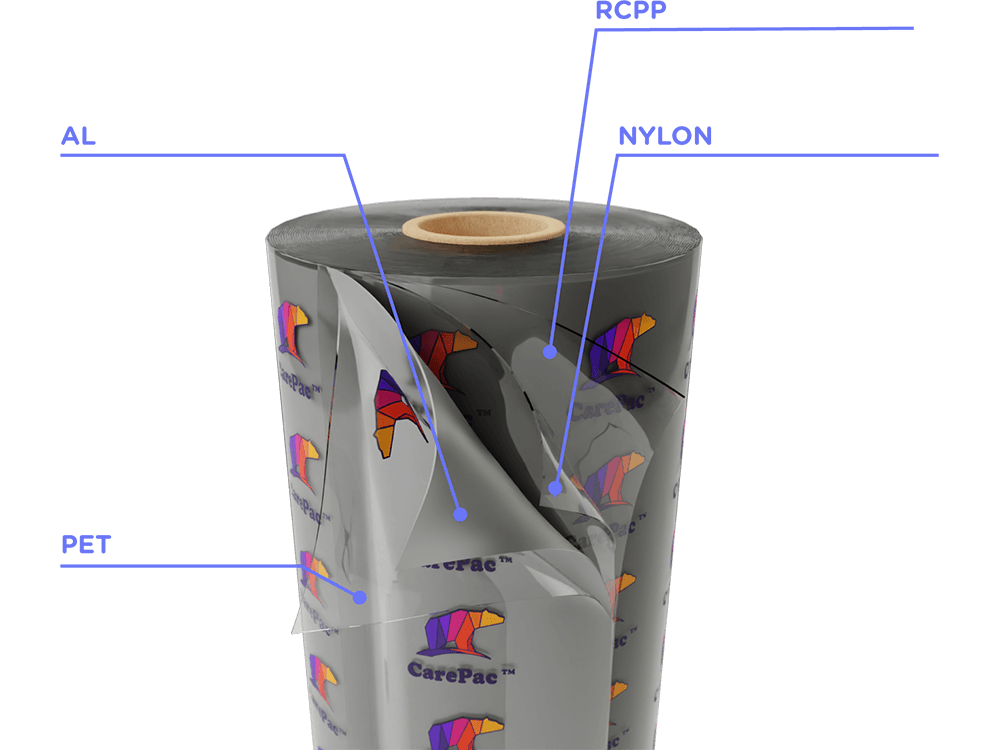

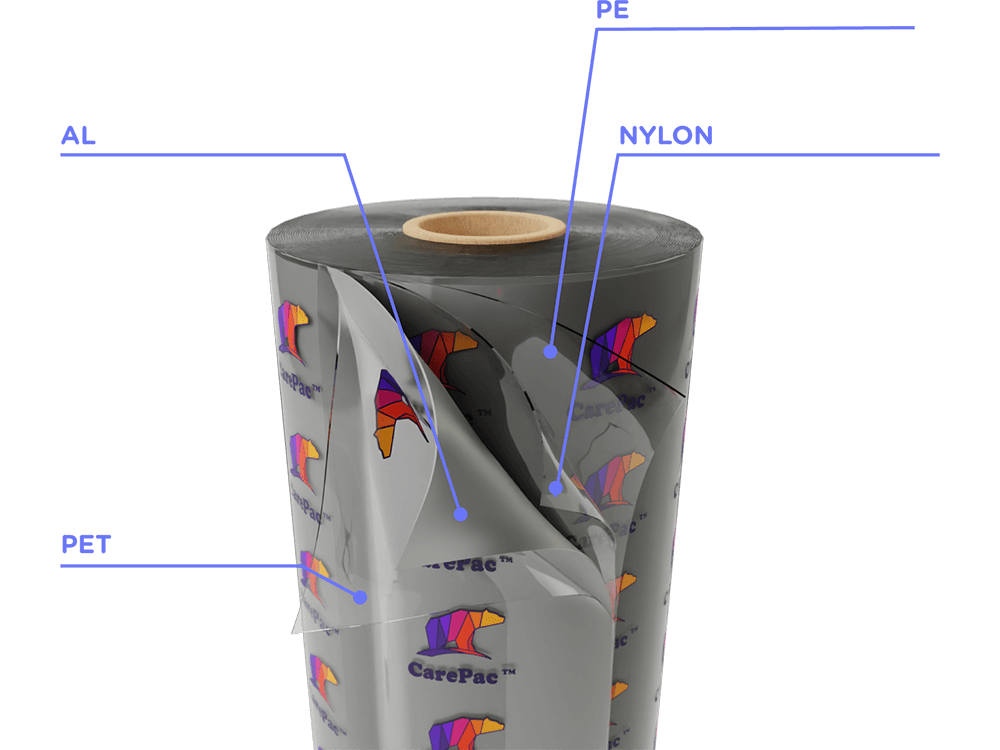

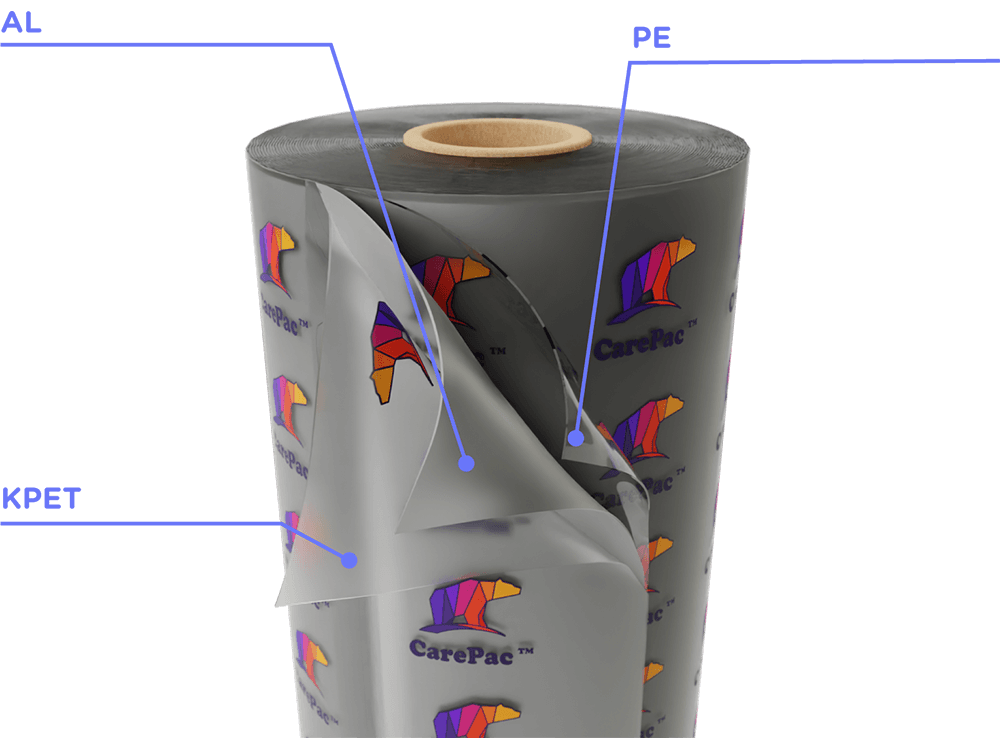

There are countless options, each with their own pros and cons. Durable plastics like polyethylene are cheap and moisture resistant, but they are conventional and have a large environment footprint. Wax coated paper packaging will be more expensive, but will add a unique appeal to your product and help reduce plastic waste. Most importantly, do research and look at your competitors to see what packaging and pouches they’re using.

#5. The Art and Science of Packaging Materials & Design

Eye-catching packaging design influences consumer decisions and perceptions, and elevates your product from your competition. On a crowded store shelf aisle, you want to stand out and become one of the favorites, and the only way to do that is to take your packaging design seriously.If you want to go from “just another product”, to an industry leader, read this next section carefully…

Color Psychology for Packaging Design: Different colors speak to us at a deeply subconscious level. And if you start to pay attention to the brands around you, you’ll start to see patterns. Certain colors can evoke emotions, influence perceptions, and drive specific buying behavior. A luxury brand might choose a refined monochrome color palette, while a brand emphasizing environmental awareness might use greens and natural earth tones. Regardless of what you choose, make sure it connects to your target consumer and the overall message of your brand

Packaging Typography: Choosing the right font is crucial to bring your brand's personality, message, and story to life. The font should align with your brand's aesthetic, voice, and packaging materials while remaining readable across various sizes and mediums. There are thousands of fonts, so get ready to experiment. If you’re a brand trying to leverage your history, try a classic serif typography. For a clean and minimalist look, try a modern and sleek sans-serif. To ensure readability on your flexible packaging and pouches, make sure your text placement is carefully considered.

Design Elements and Limited Editions: How many of your customer senses can you engage? Interactive design elements in your packaging help your product stand out and build long-term trust with your customers. These elements can be QR codes that link to digital content or even tactile textures that enhance the package itself. Carefully curated and designed limited edition packaging can also turn your package into a product itself, deepening consumer engagement and adding value and exclusivity

Sustainable Packaging & Eco-Friendly Packaging Materials

In today's market, being an eco-conscious brand that uses sustainable packaging is a win-win. Not only are you helping to contribute to a greener planet, you’re also tapping into consumer demand. Your packaging can be more than just another pouch, it can be a statement of your brand's commitment to the planet. And by choosing a flexible package option, you’re already committing to a green solution. Flexible sleeves, pouches, and containers require much less energy to manufacture and transport. And they can also be made with a variety of earth-friendly materials like bioplastics, edible material such as seaweed, and plant-based cellulose films.

When considering your eco-friendly packaging, keep these three things in mind:

Eco-Friendly Packaging Materials: Current eco-friendly options give brands an option to go beyond having just biodegradable packaging. There are numerous upcycled or recycled materials that can be used to create effective, eye-catching, and durable packaging. For example, if you’re selling organic free-range coffee, you might consider swapping plastic for an eco-friendly plant-based cellulose alternative.

Product-Package Harmony: It’s crucial that you choose the eco-friendly option that ensures the best experience for your customer. If you’re selling homemade pickles made from an old family recipe, the last thing you want is to lose that fresh out of the jar flavor. When choosing your eco-friendly flexible packaging, consider the shelf-life, temperature, and overall durability needed to ensure your product arrives pristine.

Inspiring Call-to-Action: Your packaging can also serve as a call to action. An inspirational partnership or compelling brand story can turn the ordinary to extraordinary. For example, TOMS shoes used their packaging to highlight their humanitarian mission to bring quality shoes to those in need.

Small Dishwashing Liquid Bottom Dieline 8x6

Small Dishwashing Liquid Bottom Dieline 8x6