No products in the cart.

Other Packaging Topics

Heritage Packaging Competitors & Alternatives for Custom Pouches

Heritage Packaging Competitors &

Alternatives for Custom Pouches

Established in 1990, Heritage Packaging provides unique sustainable packaging and protective packaging solutions that can't be bought off the shelf. Their team of packaging engineers, machine operators, and fabricators work together to create packaging solutions, including food packaging, for their clients.

Although Heritage Packaging is one of the leading manufacturers in the packaging industry and developed a state-of-the-art packaging feature, they aren't for everyone. If you're hoping to learn more about Heritage Packaging alternatives, you've come to the right place. In this blog, we'll discuss some of Heritage Packaging's key competitors and emerging players in the flexible barrier packaging space.

CarePac: The Preferred Vendor for Sustainable Packaging Alternatives

Unlike some of the other Heritage competitors on this list, CarePac lives and breathes flexible packaging. We have 10+ years experience in the industry, and constantly seek plastic alternatives and sustainable packaging that will help reduce your carbon footprint. If you're trying to avoid single use plastic and are looking for a biodegradable alternative that produces less waste, our solutions can help.

But, don't just take it from us. Take it from our happy customers, who said this on Google: "This company is amazing with their customer service and fast shipping. They also have a great amount of bags and pouches that your business could use. The products are durable with great quality and a professional experience. Be sure to check them out for your needs. I am positive you will be glad you did!"

Curious about our other products, our company, our business model, our services, the materials we use, cost, trends in the industry, or anything else? Browse our website to learn more or contact us today!

Other Heritage Packaging Competitors

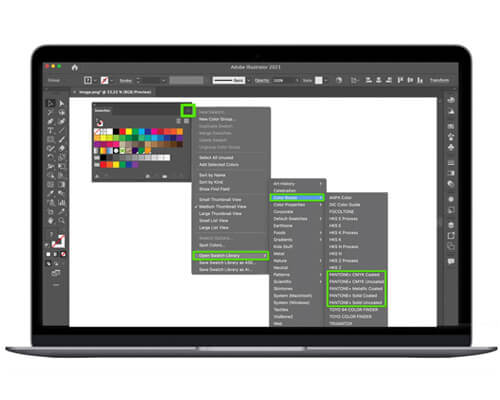

According to Semrush, an analytical tool used for digital marketing purposes, Heritage Packaging's key organic competitors include:

Heritage Container

Heritage Container is one of the leading sustainable packaging alternatives to Heritage Packaging. They believe that retail and food packaging is part of the product, and focus on offering packaging materials made out of sustainable materials. This Heritage competitor is ideal if you're concerned about carbon emissions, greenhouse gas emissions, reducing plastic waste in the landfills, your carbon footprint, and the environmental impact using single use plastic in your packaging.

The Packaging Company

Based in New Zealand, The Packaging Company is a 100% locally owned and operated packaging supplier. They have 85 years of packaging knowledge, and are dedicated to providing the best price on their packaging, promoting product integrity, and high-quality service. Although their range of packaging products includes packaging alternatives like bubble wrap, liners, cardboard boxes, produce bags, and adhesive tapes, they focus primarily on the manufacture of custom printed polythene packaging.

Victor Packaging

Victor Packaging is an innovative manufacturer of plastic tube packaging in South East Asia. Composed of six different packaging companies with 450 employees in Thailand, they offer a wide range of PBL tubes and PET bottles, primarily for the beauty industry. Their packaging is trusted by leading brands like L'Oreal, Nivea, and Amika, and their packaging can be used for a variety of health and beauty applications.

ABC Packaging Direct

ABC Packaging Direct is a global supplier of flexible packaging, including food packaging, pouches made from single use plastics, and styrofoam. They strive to be an end-to-end strategic packaging and sourcing partner for businesses of all sizes, and take a relationship-first approach to sourcing raw materials for their packaging.

The Need for Custom Pouch Packaging & Packaging Materials

In recent years, there has been a growing demand for personalized and custom packaging solutions that also reduce plastic waste and protect renewable resources. Unfortunately, due to their sheer size and market value, Heritage Packaging and many of its key competitors simply cannot meet consumer expectations for packaging in this area.

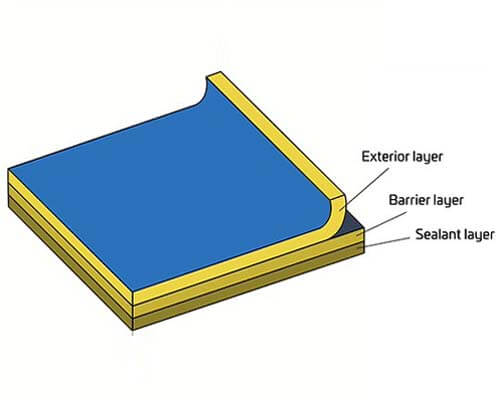

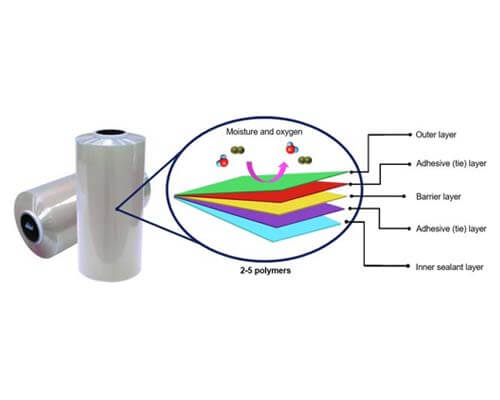

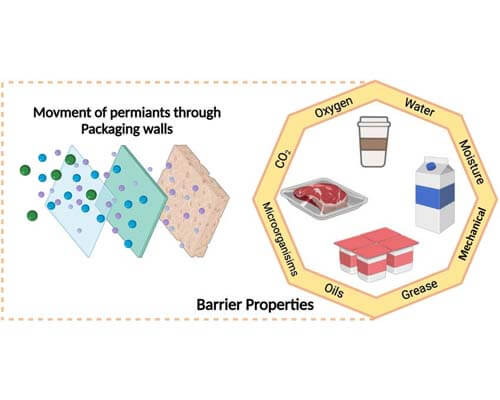

To put it simply, fully customizing a packaging product using plastic alternatives while maintaining product integrity isn't easy, and doing so while reducing greenhouse gas emissions and avoiding wasteful paper mills is even more difficult.

Fortunately, packaging companies like CarePac are moving in the right direction. We can create flexible packaging that's 100% customized, allowing customers to create eco-friendly sustainable packaging that keeps its environmental impacts in view that accurately represents your brand. From the top of the bag to the bottom, we'll find solutions for branding that you won't find elsewhere in the packaging industry and do all of this while still caring for the environment.

Emerging Trend: Sustainability and the Environment

One of the biggest emerging trends in flexible packaging centers on reducing the environmental impact of packaging materials. The three branches of sustainable packaging include landfill diversion through the development of materials that are easily processed by recycling facilities. Two, biodegradable plastic bags that customers can compost with other food waste, or send to a specialized composting facility. Third, using recycled plastic in the composition of the bags (also know as PCR or post consumer recycled.

Sales of sustainable packaging alternatives have increased each year and with the adoption of sustainability goals by large companies such as Coca Cola which plans to "[m]ake 100% of our packaging recyclable globally by 2025— and use at least 50% recycled material in our packaging by 2030."

So as the composition of the plastic that is used in bags and pouches changes, brands have to stock the biodegradable, recycled, and sustainable material that their customers are looking for.