No products in the cart.

The Role of Prototyping in Perfecting

Your Packaging Design

Nothing influences a customer's first impressions and perception of product quality more than product packaging. Customers expect their product packaging to be environmentally conscious and to provide a memorable unboxing experience. Bonus points if your product packaging can help you reduce costs, improve profit margins, and reduce your carbon footprint.

What is prototyping?

A prototype is an early sample, model, or release of a product that's built during the design process to test its construction or design. In terms of packaging, a prototype is a limited run of bags or pouches that act as a sample of what the final product will look like. Some packaging prototypes just look at size, while others can be printed with the design of your choice so you can take a final look at the pouch before you put in a larger order.

Realistic prototypes allow you to avoid costly mistakes and evaluate, test, and refine an idea before it enters mass production. The primary goal of rapid prototyping is to test the pouch for functionality, usability issues, to get user feedback, and to see all the detail of the final bag in real life. In this blog, you'll learn more about the different prototyping offered by CarePac.

CarePac's High Fidelity Prototyping Process

CarePac focuses on offering customer the most customized experience including our prototyping services. low fidelity prototypes have limited usefulness (see more below) A prototype is only useful if it accurate emulates the final product. Hence CarePac offers two main types of prototypes.

Unprinted Sizing Prototypes:

These are machine-made prototypes that are unprinted. They are effective for validating sizing, configuration, and material.

- Machine made prototype

- Great for sizing and material testing

- Lowest cost high fidelity prototype

Digital Printed Prototypes:

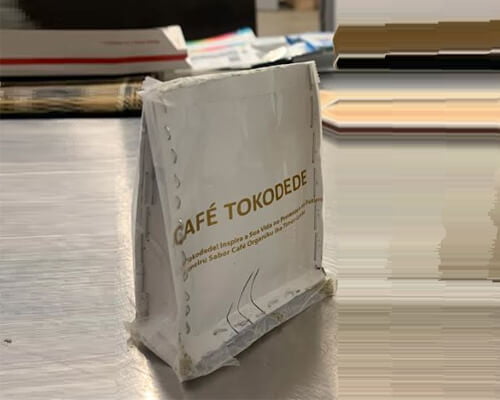

Fully customized and printed high fidelity prototypes of 100 bags. These are real bags, and fully functional prototypes made with the same processes and procedures as your final product.

- Machine made prototype

- Digital print check, sizing, and material testing

- From $250 for 100 bags

Sink Print Prototyping:

For both digital and rotogravure printed projects, we can provide a print skin. These can be thought of as high fidelity prototypes of the bags printing. These are not useful for sizing, but only for confirming color outcomes on film.

- Rotogravure printed or Digital printed prototype

- Print or color check only, not for sizing or material

- Creates delay, but no cost unless make change

Understanding Prototyping in Flexible Barrier Packaging

At CarePac, we pride ourselves on our low MOQs, meaning you can order as few as 100 functional prototype bags. Some other companies don't offer prototyping for user testing, meaning your final design is based on clickable wireframes, rough designs in mobile apps, or the most basic form of early prototyping: low fidelity sketches. Still others only offer low fidelity prototypes such as paper prototypes, and handmade prototyping these low fidelity prototypes have some uses, but here at CarePac we focus on offering high fidelity prototypes including short digital prototypes and skin print prototyping. From unprinted samples to plate printed prototypes, here's a little more information about the types of prototyping and the methods of prototyping we offer here at CarePac.

Paper Prototyping

At least in the packaging world a paper prototype is part of the design process that used by some customer to visualize the final product. A Paper Prototype is a very low fidelity prototype that is best designers to refine design thinking and processing how the design will look on a 3D surface. Paper prototypes are functionally useless beyond refining you're thinking about a pouch design.

Handmade Prototyping

Handmade sizing samples are low fidelity unprinted prototypes offered by some of our competitors which are exactly what they sound, they are a unprinted handmade bags. These handmade prototypes are a step above paper prototypes because unlike paper prototypes, handmade prototypes are made of flexible barrier material and generally to the same size as the final product.

But CarePac steers clear of handmade prototypes for several reasons. First, the seal quality of a handmade prototype will not be the same as a machine made product, So handmade prototypes cannot be used for technical testing (blow out, seal strength, MVTR, or OTR tests, etc). Second, if sizing is what you are wanting to confirm, why not just invest in high fidelity prototypes such as our digitally printed bags? With high fidelity prototyping you can also confirm print placement or color along with other physical parameters and material performance. Third, if the prototyping is for color check, only a high fidelity prototype such as a digital prototype or a skin print will get you close enough to the final product to satisfy what you want.

Unprinted Sizing Samples (low fidelity prototypes)

This is exactly what it sounds like: an unprinted bag that's perfect for people who are only worried about the size of the bag (not its design concepts or uncovering usability issues during usability testing.) These bags are unfinished and unprinted, and are built to the specific sizing you provide and with the material you want to use on the final product.

We consider these machine-made sizing prototypes to be a mid-ground between low fidelity prototypes such as paper prototypes or handmade prototype bags, and the high fidelity options of a digitally printed prototype or a skin print prototype. The real advantage of the unprinted sizing sample is you can try to fit your product into the prototype so you know it'll fit into the final version of the bag or pouch. You can also test other physical attributes of the bag. Finally, it can also help with your design thinking process, as it's a 3D object you can sometimes better visualize where you want the art placed as opposed to using paper prototyping, or other low fidelity methods.

Digitally Printed Prototyping

CarePac's digitally printed high fidelity prototypes are micro short production runs of as few as 100 bags (or 1 bag if you really just want 1 bag), and these digital prototypes can be printed onto any custom size bag you'd like, with almost any material we work with here at CarePac. Many of our customers prefer a digital prototype for a variety of reasons beyond prototyping, such as trade shows, promotional events, influencer targeting and more. The most common use of high fidelity digital prototyping, including the below.

Solidify Sizing

The digital prototyping process helps you ensure that the size of the bag is correct for your product. If the lo-fi prototypes are too large or small for your product, you can adjust. Again unlike paper prototyping which leaves room for error and differences in how the material reacts, our digital prototypes are made on the same machine and using the same processes as your final product would be.

Performance Testing

CarePac's hi-fi prototypes can be fully customized and made with any material we can source which allow you to conduct performance tests, so you can make sure the material meets the needs of your application (ex: you can perform test shipments to make sure the bag doesn't burst during transit.) A common use case for our high fidelity digital prototypes would be protein powder. A low fidelity prototype like a handmade sample or paper prototype cannot be used to test whether the bag will hold up to rough handling in an Amazon warehouse.

Meeting Preparedness

Gives you the opportunity to show actual samples to prospective retailers and distributors. Instead of showing up to a meeting with just an idea for a preliminary model, you can actually show up to the meeting with a finished product that shows off your bags interactive elements. This really is a great example of the difference between a low fidelity prototype, such as a paper prototype and high fidelity prototypes that we can make here at CarePac.

The old saying "Fake it until you make it" comes into play here, but in all honesty, retailers, distributors and partners can better visualize your product and its place in their store when you provide a fully finished and printed bag prototype. Spending a few hundred dollars for high fidelity prototyping from CarePac could land you a six figure distribution deal, and we think you'll agree it's worth it on so many levels.

Skin Print Prototyping Method (another high fidelity prototypes)

Think of this as a high fidelity prototype: it allows you to confirm the colors of your project on actual printed material. Using hi-fi prototypes is great if you plan a long run and want to confirm how the colors perform on the actual material of the bag. For example, if your UX designer or UX design team prefers using a specific CMYK color on a specific material but the prototype and focused feedback shows that the color bleeds into the material, you may want to consider a different material or color.

This is also important because sometimes colors look different on different screens than they do in real life. You'll want to see what real users will see - not what your design team sees on a screen.

Plate Printed Prototypes

This is the most complex kind of prototyping, as it requires us to use plate printing (to learn more about the complexities of plate printing, you can read more here.) With this prototyping process, your design team will lose nothing but time (approx. 2 weeks) if you approve the skin print as is. But, if you want changes after the skin print, you'll incur the costs associated with making the change in addition to the costs of the time and the material to print along with any plate remakes.

For this reason, we recommend skin print digital prototypes unless you are only checking for PMS color accuracy.

Benefits of building prototypes during packaging design

There are quite a few benefits to using a physical model of your bag or pouch to test ideas among real users.

Risk mitigation

Relatively speaking, incorporating interactive prototypes into your design thinking process requires minimal effort. And it's, quite simply, the best way to catch mistakes before your bag enters mass production - potentially saving you time, money, and embarrassment.

Enhanced communication

Using a high fidelity prototype during the design process allows design teams, clients, and manufacturers to discuss the user's journey and how the final product will satisfy user needs.

User testing opportunities

Last but not least, the only way for a UX design team to understand if their product satisfies user needs is by leveraging popular prototyping tools and services (like CarePac) during the development process.

Other types of prototyping techniques

There are a few different types of prototyping techniques, from clickable wireframes and audio simulations to mid-fidelity prototypes. Here are some of the user driven prototypes used by the packaging industry.

3D printing

This is one of those digital tools that's a good choice for complex designs since it allows for the rapid production of detailed models. One thing to keep in mind, though, is that the 3D printed version of your pouch may not be of the same material as your final product, as the types of materials that can be used with 3D printers is still limited.

Mock-ups

Primarily used for visual presentations, this is a type of low fidelity prototyping that is less functional but visually accurate. You won't be able to hold the finished product in your hand, but it can be a good way to test ideas related to marketing or branding during internal meetings. Mock-ups are often leveraged earlier on in the design thinking process.

Digital simulations

Useful for initial design evaluations, digital prototypes can help teams validate ideas without a physical model. These high fidelity prototype tools involve creating a visual representation of the packaging, that often includes logo placement and the intended user interface.

Physical prototypes

Physical prototypes are, simply put, the best type of prototyping. It allows teams to validate ideas, handle the finished product in real life, pursue user testing, and see each step of the design thinking process come to life. These prototyping tools create existing objects that can be passed around a room, and is a much better option than some of the low fidelity prototyping on this list. CarePac digital prototypes are physical prototypes.

We can help you choose a prototype technique

Each of the above method has its own place, depending on the complexity, materials, and specific project requirements of the final product. Fortunately, CarePac can help you select and create prototypes that are most appropriate for your project.

How to integrate prototyping into your workflow

If you'd like to create prototypes for your company, you may be wondering how to incorporate these user driven prototypes into your workflow.

Engage the team early

In order to best incorporate prototyping into your design process and thinking, introduce it as early on in the process as possible. This allows enough time for refinement.

Take a collaborative approach

Encourage all members of the team to be involved in the creation of physical models through prototyping. This includes designers, engineers, and manufacturers. Each of these groups will likely have something unique to contribute re: user interfaces and how the prototype will help the overall design process.

It's an iterative process

View prototyping as an iterative process, where each prototype brings you closer to the ideal final product. Very few companies move forward with their very first prototype; instead, they tend to go through a few physical models before they decide on the right one for them. Whether you choose low fidelity or high fidelity for your prototyping, any such prototypes will greatly improve the success of your final product.

CarePac: Your partner in packaging prototypes

Prototyping involves several areas from design, to function, and can be more complex than you'd think, but CarePac can help. If you're interested in leverage high fidelity prototypes for your company, connect with us to get your project started. You can also order samples here.