No products in the cart.

Barrier Packaging Guide

Choosing the right packaging materials for your product can be a daunting task. Not only does the packaging need to look great, but it needs to protect the perishable products within, working to extend shelf life and extend freshness. Additionally, you'll need to take a variety of things into account: how long will the product be in storage? Will it be stored in a climate controlled environment, or outside in a hot and stuffy warehouse? Does the packaging require more than one layer of protection, or just one?

Fortunately, you're not alone in your hunt for the perfect barrier packaging material. Our barrier packaging guide will walk you through some of the most common questions we receive about barrier packaging, the advantages of an oxygen barrier, and more. Welcome to our guide to barrier packaging, created by the people who know barrier packaging best.

What is barrier packaging?

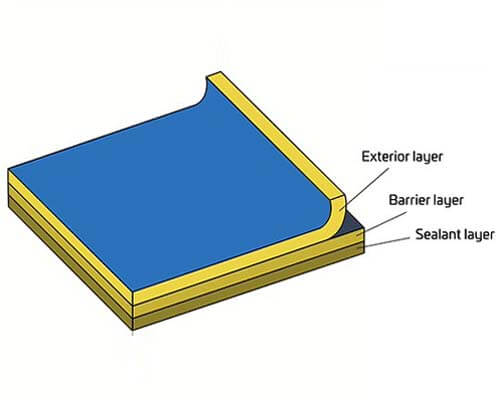

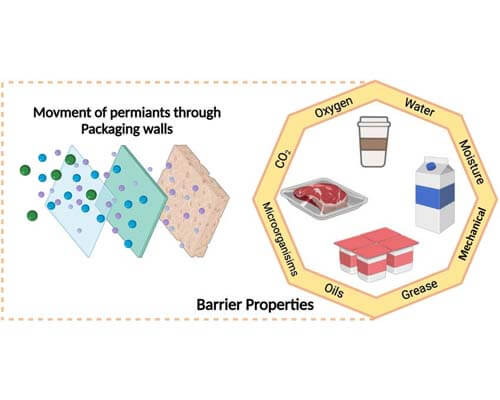

First things first: what is barrier packaging? Barrier packaging is any packaging that prevents the migration of moisture, gas, or oxygen through the packaging, creating what some refer to as a modified atmosphere package. This barrier can be thought of as a firewall, preventing the movement of gas or liquid. In short, barrier packaging is made from a packaging material that provides a high barrier between the product inside and oxygen, moisture, light, and gas. In some cases, barrier packaging can also act as an aroma barrier, keeping products fresh and odors and scents inside the plastic bags.

How is barrier measured in packaging?

The two main measurements of barrier are moisture vapor transmission rate (MVTR) and oxygen transmission rate (OTR). There are other measurements, but for food products these are the most common measurements. Learn more about what exactly these measure in regards to barrier packaging materials.

Moisture vapor transmission rate

This is measured using standardized testing protocols from ASTM or ISO. Grams per square meter over 24 hours (g/m²/day) is a common measurement, and it measures how many grams of moisture are transmitted through the packaging material in a 24 hour period. In the United States, some companies use grams per 100 square square inches over 24 hours (g/100 in²/24 hr) which measures the amount of moisture passing through 100 square inches of material in 24 hours.

Oxygen transmission rate

Typically measured in CC/100in square in 24 hours (cc/m²/day), this measures the amount of oxygen that passes through the material over a specific area across 24 hours. In the United States, some companies use CC/100 in²/day, which measures square inches per 24 hours.

Understanding these common measurements for barrier packaging materials can be confusing, which is why it's so important to work with a professional and experienced packaging company, like CarePac. We'll walk you through the various oxygen and moisture barrier properties, ensuring that the packaging material you choose has the barrier properties you need.

What are the different levels of barrier protection in packaging?

When it comes to understanding the different barrier levels of plastic films, they're typically divided into four categories: basic single, basic double, moderate, and high performing. Each level offers a stronger oxygen and moisture barrier and the barrier strength increases with each step up. Here's a little more information about the barriers and the metallized films that fall within each category.

Basic Barrier- Single Layer

This offers your most basic level of moisture and oxygen barrier. It temporarily protects the product within from exposure to light, oxygen, and moisture, but won't do much to extend the shelf life of the product. Think of this as your most basic low barrier material, such as the monolayer materials that make up a sandwich bag. If you're on the hunt for a high barrier material, keep looking!

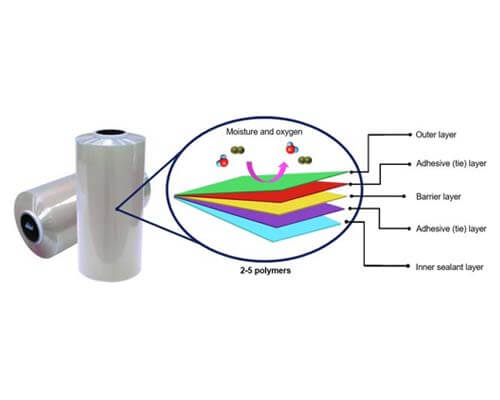

Basic barrier- Multilayer Materials

Basic barriers that use multilayer materials are still relatively "basic" in nature, but they do offer enhanced protection when compared to a basic barrier with a single layer. Often associated with laminated packaging, you'll often see a combination of materials in a double layer barrier. For example, PET/PE combines polyethylene terephthalate and polyethylene, OPP/PE combines oriented polypropylene and polyethylene and OPP/OPP has two layers of oriented polypropylene.

Polyethylene Terephthalate (PET) provides a good barrier against gas, moisture, and aromas, and is often used in multilayer basic barriers.

Moderate Barrier

A moderate barrier will often protect against gas, moisture, aroma, and sometimes UV light. These coated films are lightweight and food safe, and are often used for food packaging. CarePac's PET/VMPET/PE is considered a moderate barrier material, and the metallization of these films offers an enhanced oxygen barrier. Unlike the basic barriers, a moderate barrier can help extend the shelf life of food, pet treats, and other items.

High performing barrier

Finally, high performing barriers are made up of multiple layers of heavy duty materials. Our high performing barriers protect against odor, moisture, gas, UV light, and visible light, and will keep the product inside fresh. If you're concerned about your product being exposed to gases, chemicals, and other detrimental elements in the environment, choosing a high performing barrier is essential. CarePac's PET/AL/PE bags use aluminum foil as the middle layer, which has incredible barrier properties, and is nylon reinforced for super protection and durability.

Which barrier should you choose?

So, which level of barrier protection is right for you? While a higher barrier is always better, especially for food products, excessive barrier is just a waste of money. Selecting which level of barrier you need also depends on a variety of unique factors, such as whether or not you need a window to view the product inside. For example, if you don't need a window, choose a metalized material with a better barrier.

We know this can be incredibly confusing, which is why it's so important to work with an experienced and qualified packaging company that's well versed in flexible packaging and barrier properties. Curious about the advantages of one barrier level over the other? Need help with the development of your packaging? We can help! Contact us today!