No products in the cart.

Food Industry Packaging, Other Packaging Topics

Meeting Food Safety Standards for Large-Scale Distribution

Meeting Food Safety Standards for Large-Scale Distribution

Why Food Safety Standards Matter for Large-Scale Distribution

Food safety is critical for large-scale operations because it protects consumers from potential hazards, can help prevent cross contamination, and reduce the likelihood of food-borne illnesses from inefficient processes or dirty equipment. Not only do food safety regulations protect consumers, but good manufacturing practices can protect food manufacturing companies from legal repercussions and severe damage to their reputation.

Regular inspections, refresher training courses, adhering to regulatory requirements, routine pest control, proper storage processes, equipment inspections, and good record keeping can reduce food safety risks and enhance consumer trust. Risks of non-compliance with established regulations for food manufacturing facilities include product recalls, health hazards due to an increased risk of cross contamination, legal issues, and a loss of consumer trust.

Fortunately, a comprehensive food safety manufacturing plan, including proper packaging and distribution practices across the food industry, is essential to preventing food-borne illnesses and maintaining consumer confidence. Even if your customer will end up cooking the food, the bulk of food safety falls on food manufacturing companies.

Key Food Safety Regulations for Large-Scale Distribution

Major food safety regulatory bodies in the United States include the FDA, USDA, and the Food Safety Modernization Act. These regulatory bodies provide general guidelines for food safety across many aspects of the food industry, including food production and food manufacturing, how raw materials are handled during manufacturing and distribution, and safe food handling practices. Below we'll discuss a little more about these food safety procedures and processes.

FDA Food Safety Standards

The food safety guidelines outlined by the FDA focus on proper food manufacturing processes, including sanitation, hazard analysis, and critical control points for food production facilities. The FDA has very specific regulations for different food categories, including seafood, juice, frozen food, and quality standards for other foods. They also regulate the proper temperature a food thermometer needs to reach to prevent foodborne illnesses and things like avoid thawing chicken under cold water.

Food Safety Modernization Act (FSMA)

The Food Safety Modernization Act requires food facilities to develop and implement food safety plans and tips with hazard analysis and risk-based preventive controls. Key components of the FSMA include regulations for handling fresh produce and specific food safety temperatures during transportation.

USDA Food Safety Requirements for Meat, Poultry, and Dairy

The USDA food safety regulations focus on meat, poultry, and dairy specifically. Their corrective actions include mandatory inspections of meat and poultry processing plants, which includes pathogen testing and grading based on manufacturing quality. Not only do they focus on the food production process, but they also have strict guidelines for distribution of food products, so the meat, poultry, and dairy products are regulated throughout the supply chain.

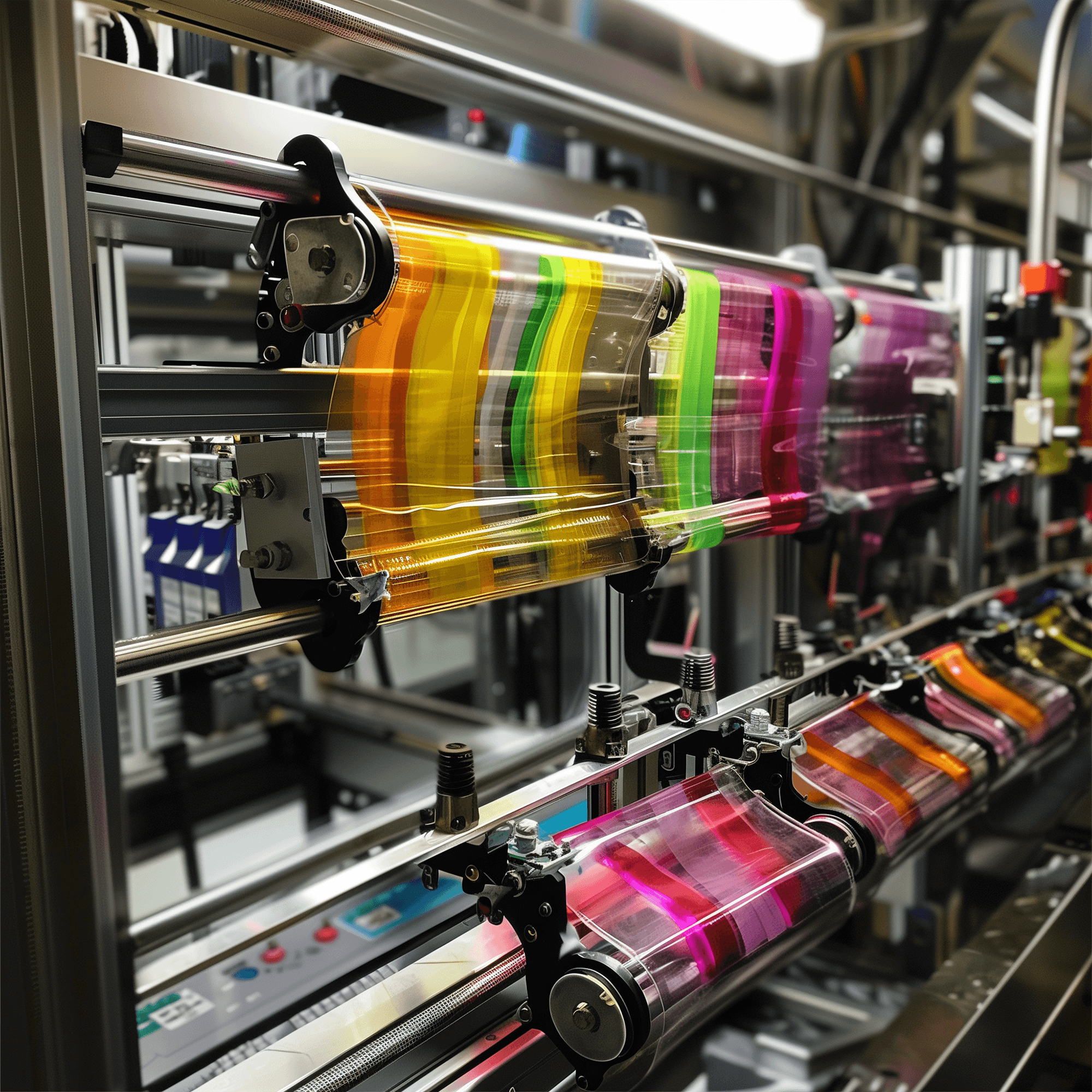

Food Safety Packaging Best Practices for the Food Industry

When it comes to food packaging and safety, specifically, there are several food safety best practices to keep in mind. These are intended to protect the safety and quality of food products as they make their way through the supply chain. Below are a few things to keep in mind:

Choose the Right Packaging Materials

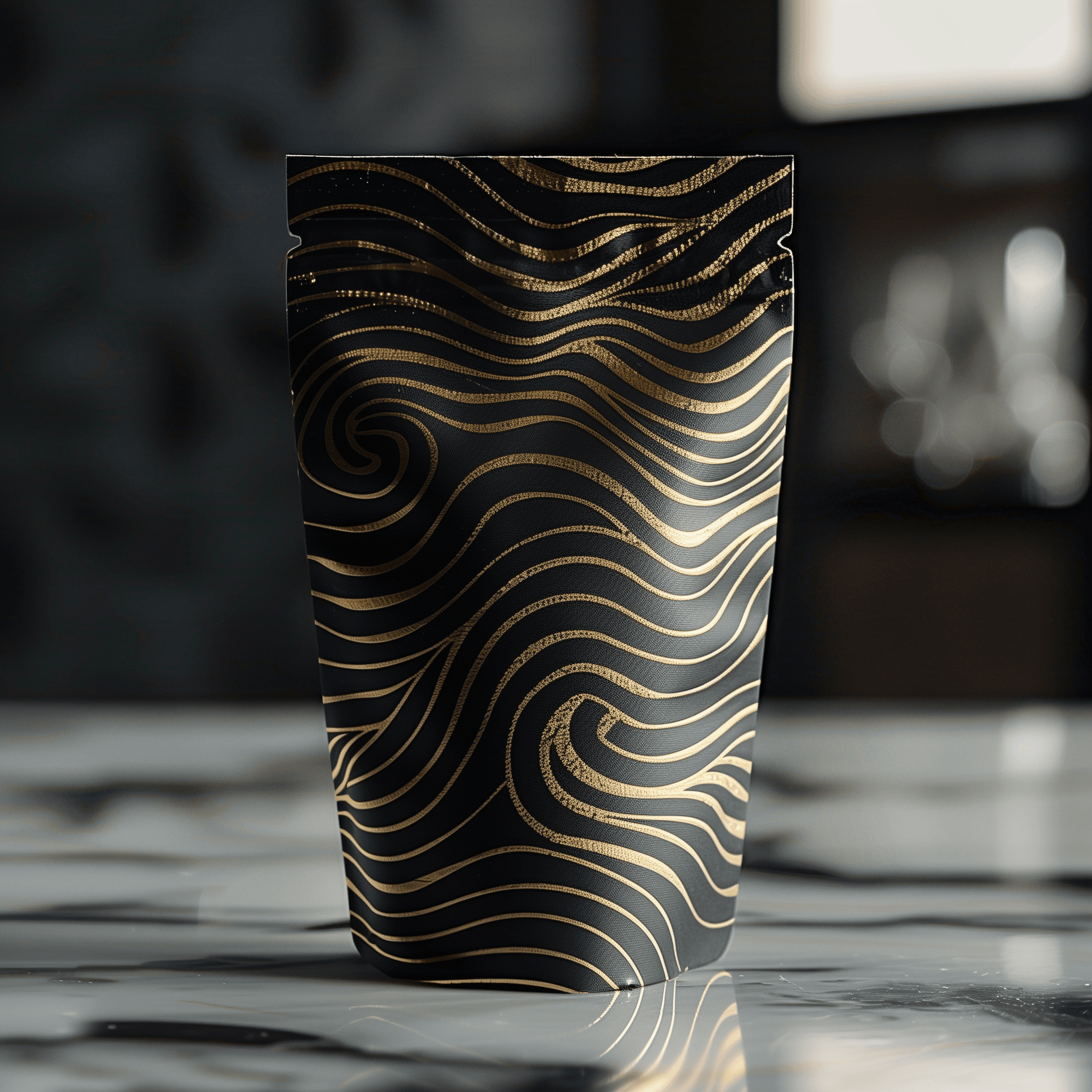

To adhere to the critical control points for food packaging, you'll need to choose packaging that's FDA-approved, durable, and leak-proof. Proper packaging can prevent raw materials from coming into contact with each other during transport and protects things like fresh beef and dietary supplements from spoilage during transport. Browse our materials here.

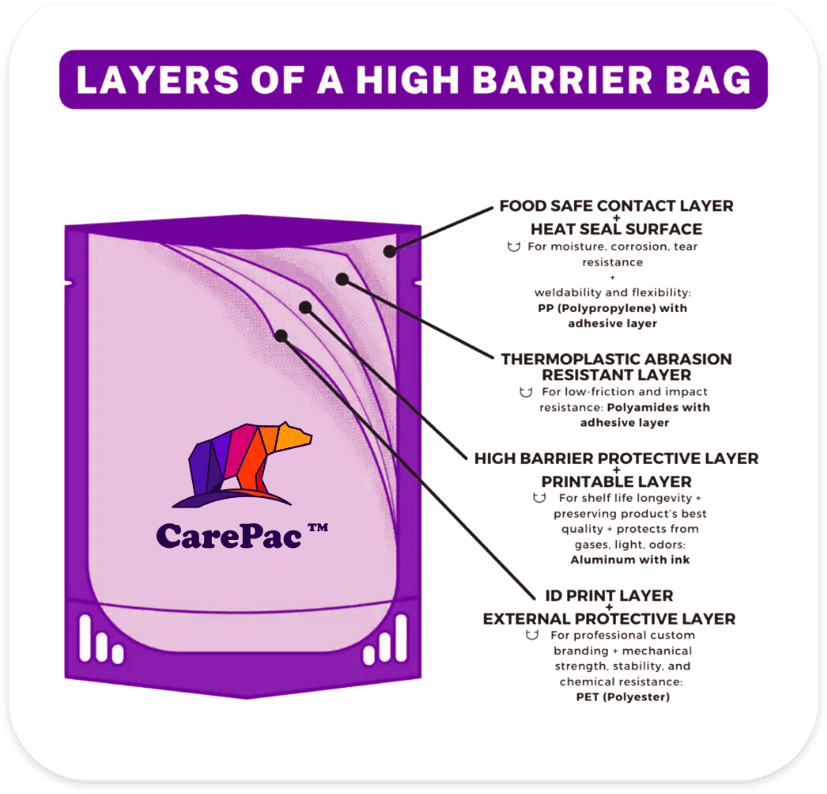

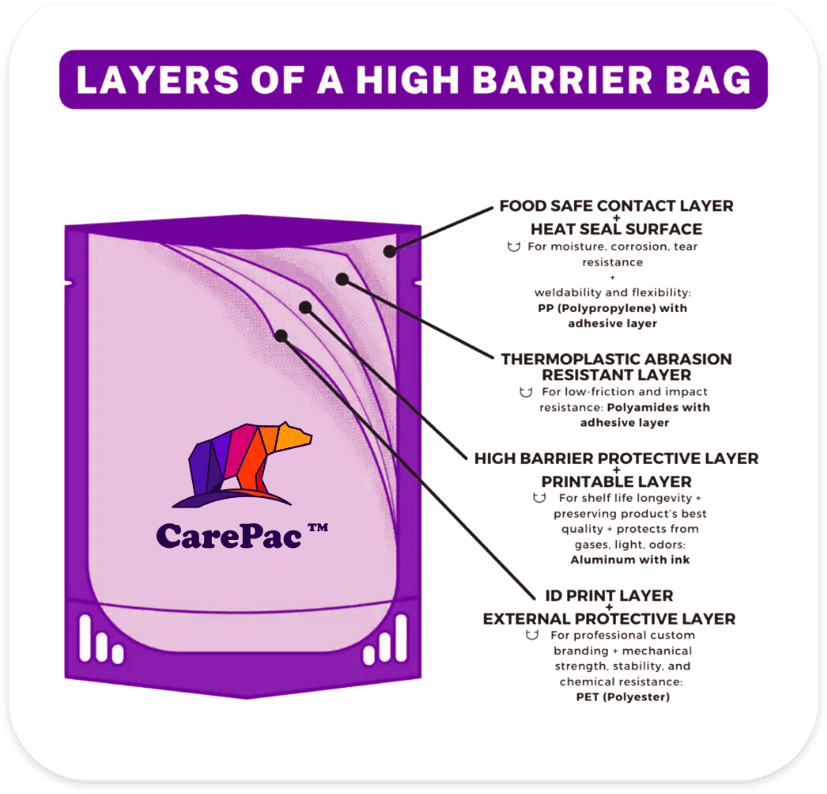

Pay Attention to Barrier Properties

By selecting the appropriate barrier properties, you can prevent moisture, oxygen exposure, and contamination. After all, what's the point of going through risk assessment, training programs, and maintaining proper hygiene and equipment safety at the food manufacturing plant if your transport and storage practices cause the food to spoil before arrival?

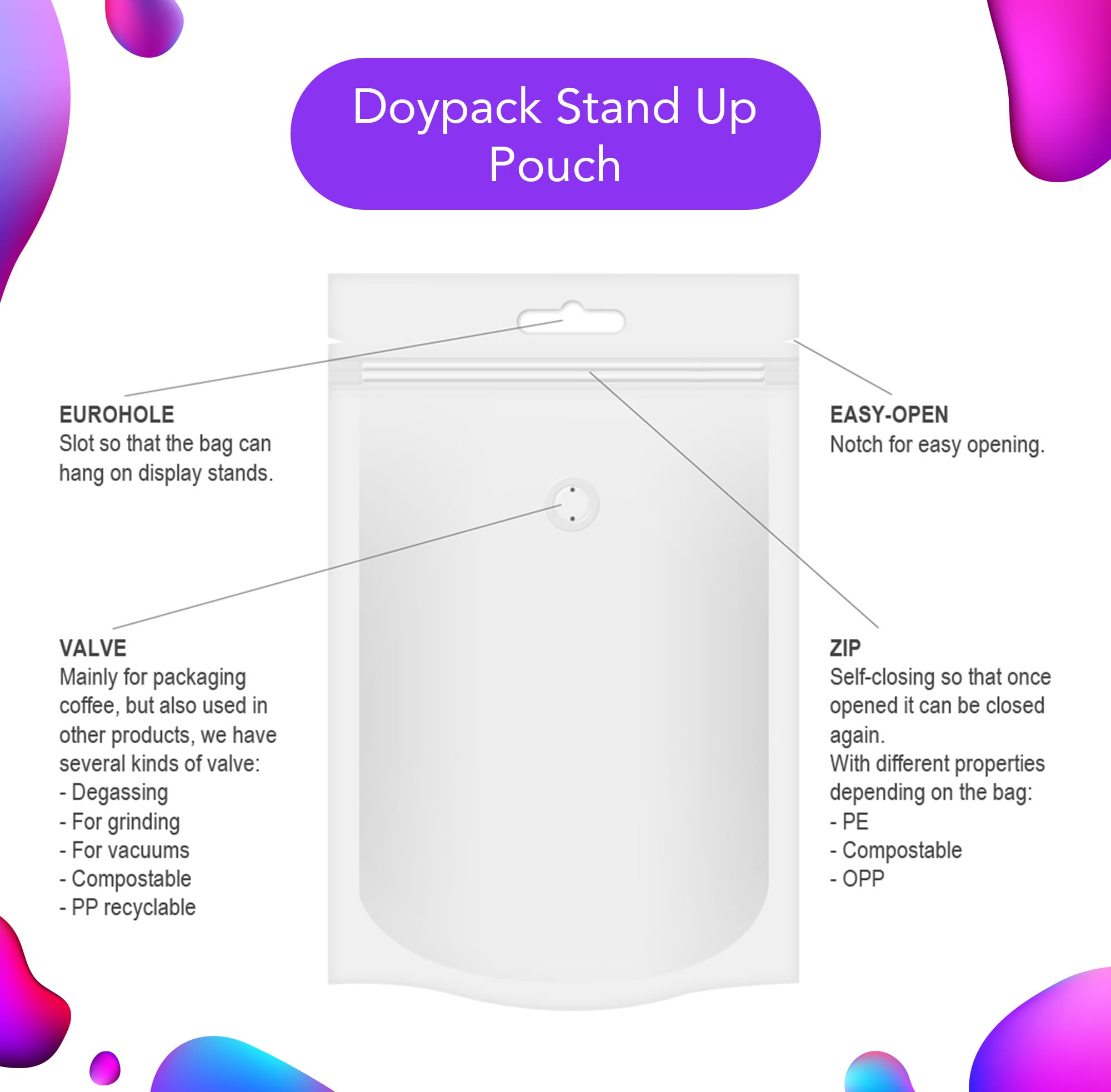

Use Tamper-Proof and Resealable Features

Another important thing to keep in mind is adding tamper-proof or resealable features to your packaging. Although these safety standards aren't mandated by the FDA or USDA, it can enhance food security during transit and throughout the food supply chain. The best food defense is taking the extra steps during both transport and during the manufacturing process.

Preventing Contamination & Ensuring Safety Throughout Food Production & Distribution

There are several food safety best practices to keep in mind as you package and distribute your product, whether you're producing raw materials like flour or sugar or processed food products that are ready-to-eat. These corrective actions and internal processes can help ensure your products meet safety standards and protect the American food supply chain from major issues.

Temperature control & cold chain logistics

Ensuring proper temperature control and cold chain logistics throughout your operations can help keep perishable foods safe. Even if your customers will be cooking food to the appropriate temperature before eating, the responsibility still falls on you to maintain the proper temperature of your finished products during transport.

Proper storage & handling

If you haven't already, you'll need to come up with standards to help avoid cross-contamination in warehouses. Some standards to consider include how to handle dirty cutting boards, if your employees need to change clothes after coming in contact with certain raw materials, hygiene standards for your employees and contractors, washing hands with soapy water, ensuring running water in your facility is clean, and outlining other operations processes you can think of.

Labeling & tracking

Another thing you'll need to ensure is accurate food product identification for consumers. Do your labels outline proper cooking instructions? Does it provide tips for keeping the food fresh and safe? Food safety might start with the individuals in the food manufacturing industry, but it ends with the consumer. Make sure they have the hygiene and sanitation tips they need for proper cooking, storage, or consumption.

How CarePac Helps You Meet Food Safety Manufacturing Standards

When it comes to food safety, compliance with food manufacturing regulations isn't just important—it’s essential. Our food-safe packaging solutions are designed to help food manufacturing businesses meet strict FDA, USDA, and other industry standards. Our packaging is made from food-grade materials that meet regulatory requirements and will protect your food products against product contamination. This way, your food products stay safe for consumption throughout their life cycle.

We're proud to provide custom packaging solutions for large-scale food distributors, whether you need packaging for bulk food distribution, ready-to-eat meals, or fresh food products, like fruits and vegetables. Choose barrier films, resealable pouches, and tamper-evident options to ensure the safety and quality of your food after manufacturing.

Don't leave the safety and quality of your food to chance. Contact us today to find the right packaging solutions that will keep your business compliant and customers safe.

Packaging for Food Safety: FAQs

Here are some common questions we receive about food safety and how it is impacted by proper packaging.

The best packaging for food safety should have strong barrier properties. Materials like PER, HHDPE, and PP can enhance food safety while providing you with plenty of customization options that will help your product stand out on the shelves.

If you're concerned about food safety, the best packaging for food safety is airtight, non-porous, and made from materials like glass, stainless steel, or food-grade plastic. CarePac can help you enhance your food safety with our premium packaging.

Lets Get Started

Made In

The USA

Full Pouch

Customization