No products in the cart.

Flexible Barrier Packaging

The Best Food Packaging to Keep Your Brand’s Products Fresh

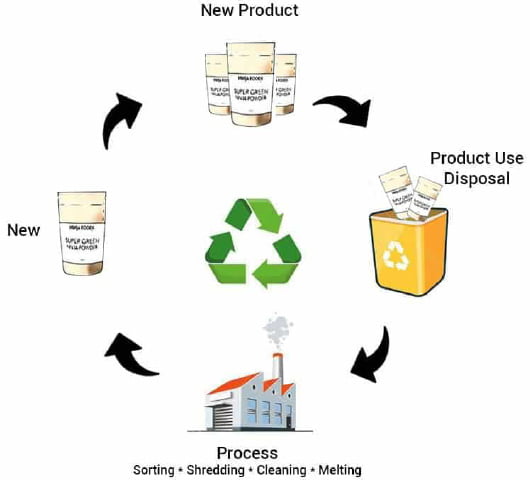

When taking an eye catching sealed bag from the store shelves, consumers may assume that the content's freshness is assured by its packaging. The cookies, fruit, or candy will only be at risk of getting stale after the food packaging is opened once they leave the single store. This directly impacts the food industry, food brands, and target market.

Good qualities like freshness, crispness, and taste and something that extends shelf life are high-priority functions of both consumers and the food packaging industry. But in reality, the food packaging's protection of the contents of a bag is limited to an extent. And that depends upon the design and quality of the food packaging.

This is a good example of why new packaging designs you create need to take shelf life and package design testing into consideration. If your food products have the unexpected twist of being stale, your packaging design process, and perhaps the containers themselves, need to improve.

A teeth-cracking hard protein bar with natural ingredients, a soggy cookie in different flavors, or pet food that has gone bad can create attention in the wrong way and scare away consumers from brands, no matter how good the food packaging design is.

There are two great villains that cause a food product to deteriorate inside the packaging: poor food package design and packaging materials. Both are no-nos for your customers.

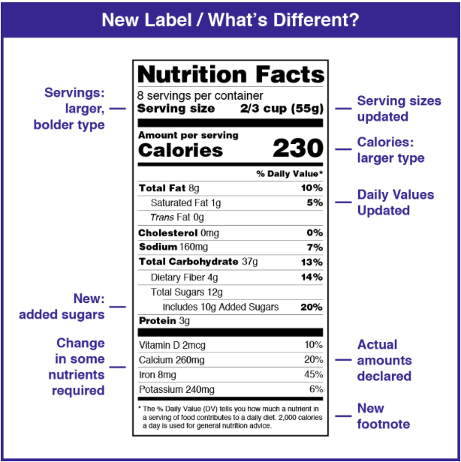

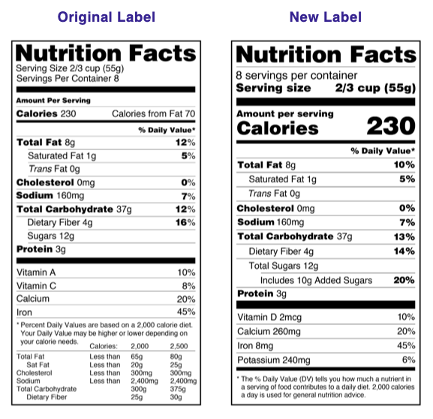

MVTR and OTR for Food Packaging

Moisture Vapor Transmission Rate

The Moisture Vapor Transmission Rate (MVTR)—also called the Water Vapor Penetration Rate (WVPR) - is a measure of how much moisture gets into food packaging over a certain time interval. Depending upon the content and how long it is exposed, the results can vary greatly.

Oxygen Transmission Rate

The Oxygen Transmission Rate (OTR) is a measure of the product's exposure inside the food packaging to oxygen. Oxidation of the product in the bag is the chief contributor to what we called staleness—a diminution of the qualities of texture and taste.

If these problems are not anticipated during the planning stages, then unfortunately the customer experience with your packaged products, even sustainable packaging, may be negatively impacted. Consumers may or may not check for a use-by date on the bag—and the reliability of the freshness date, of course, is limited by appropriate packaging.

At Carepac, we are dedicated to food product safety and go to great lengths to ensure your product packaging design is up to date with the highest standards. Fortunately, there are reliable standards for measuring MVTR and OTR and, in addition, accurate instruments for making those measurements.

International Standards, Food Trends and

Accurate Packaging Testing

Both the vapor and gas that get into food packaging are measured using tests defined by two standards:

ASTM International

The International Organization

for Standardization

ASTM International, as the name implies, is an international standards organization. It works out and publishes voluntary consensus technical standards for many products and services. (Formerly it was called the American Society for Testing and Materials.)

The International Organization for Standardization performs the same functions, bringing together representatives from national standards organizations to develop and publish worldwide technical, industrial, and commercial standards.

Calculating Packaging's Barrier Materials

Against Penetration

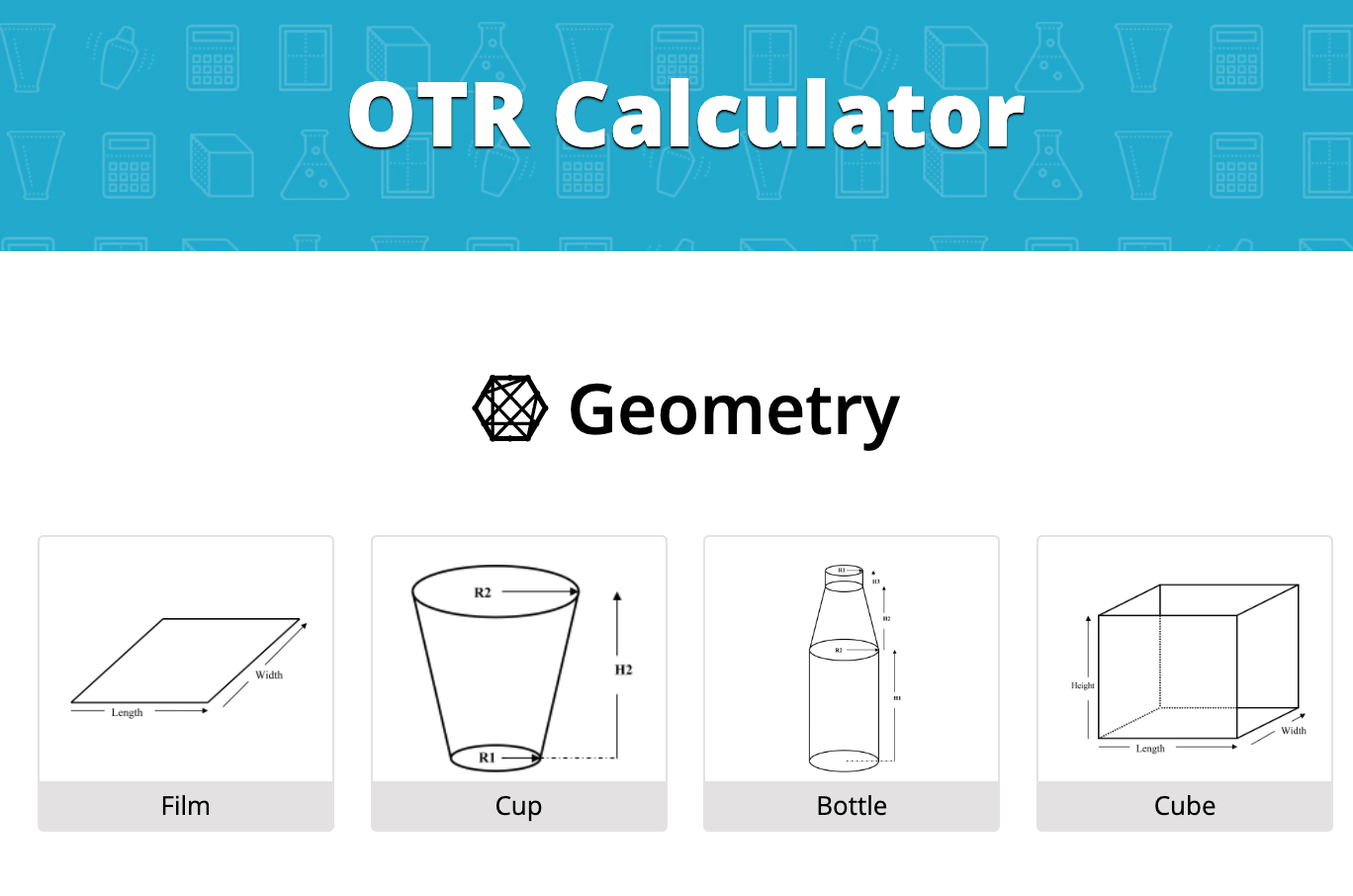

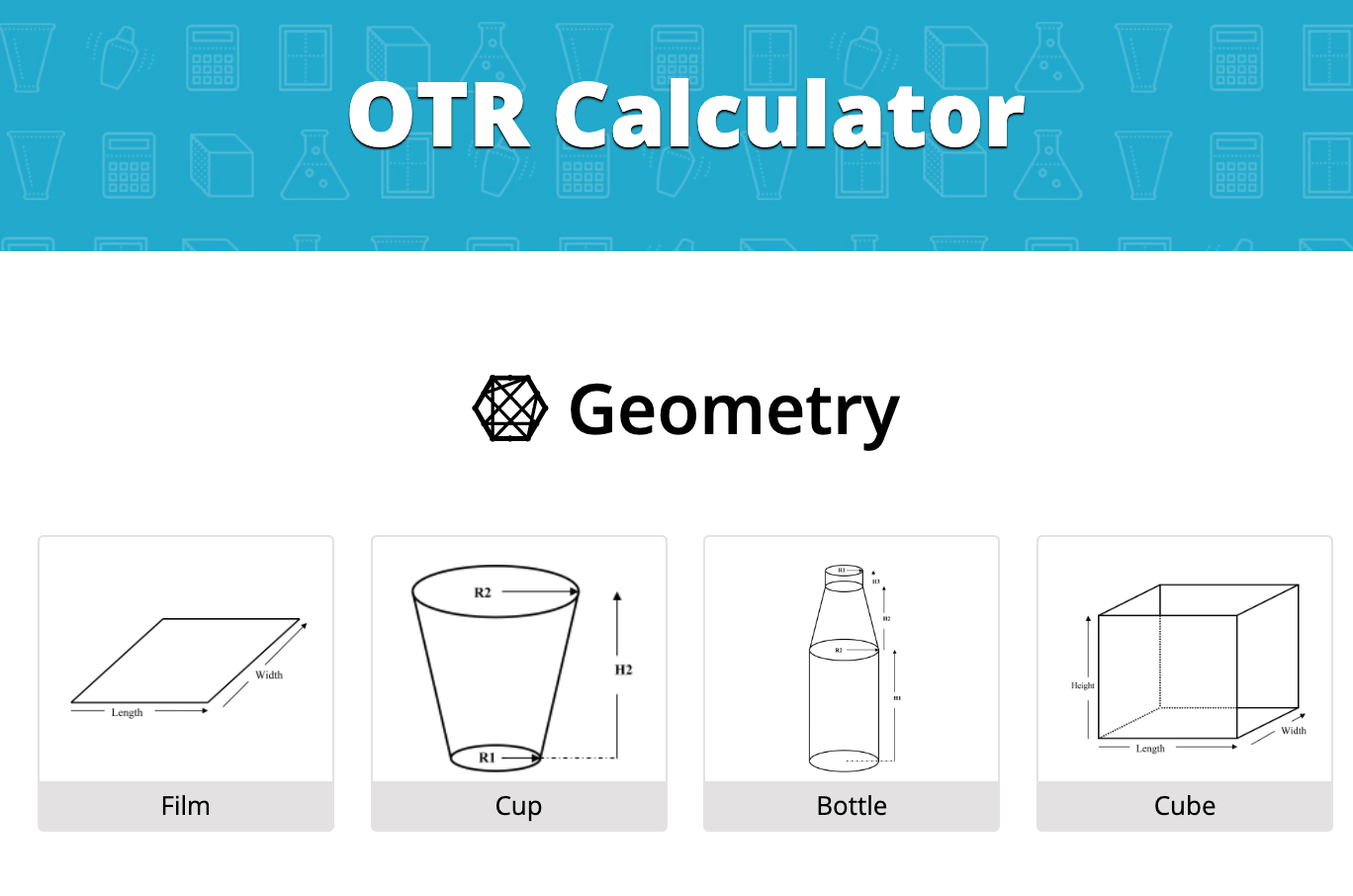

One useful and reliable calculator of the food packaging barrier against moisture or oxygen provided by a given packaging is the Norner Barrier Calculator (a free version can be accessed here: https://barrier.norner.no/.

Norner Barrier Calculator

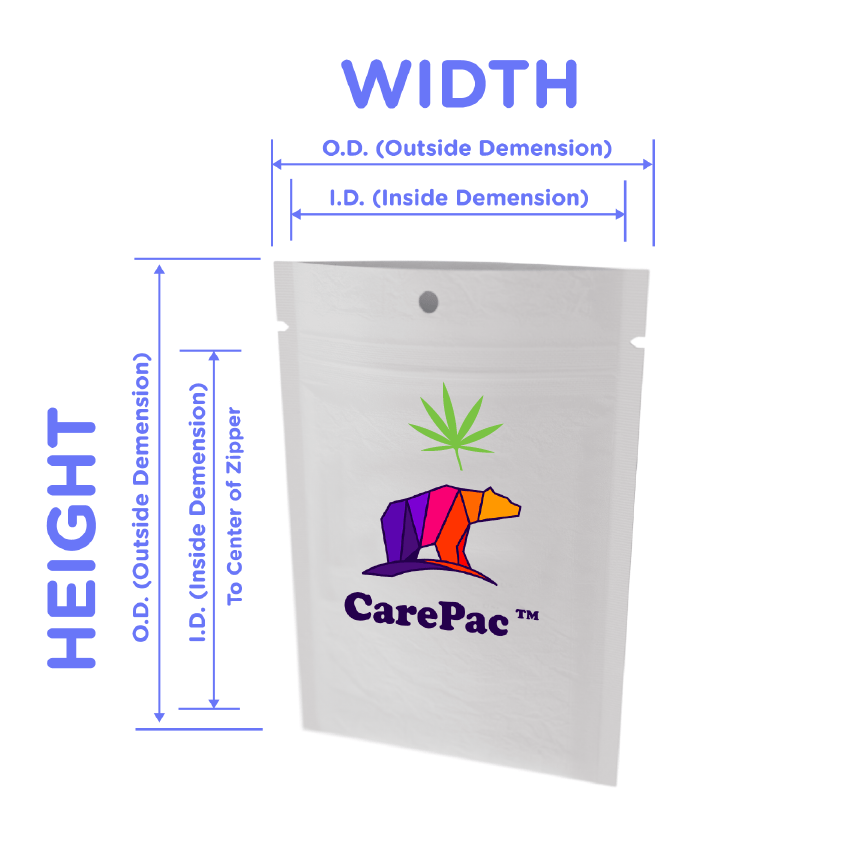

The calculator allows you to select different packaging geometries such as film, cup, bottle, and cuboid. This simulates your target packaging design. The calculating models then put out an estimate of the water vapor or oxygen transmission rate through various plastics, including, of course, packaging material. This way, you know how it will impact the quality of your consumers product.

Barrier properties of limited types of food packaging can be best studied by this means and changes in layers, geometry, and in-mold label can be tested and compared. The results make the calculator a highly useful tool for designing and developing packaging with reliable performance in protecting different products in different conditions of storage and exposure.

Typically, the tests measure the number of grams that are lost or gained through a barrier over a given period, such as 24 hours. Since transmission through a package (or its penetration) is to be controlled, the lower the readout, the better. A number lower than 1 gram is considered a high barrier material.

The challenges:

finding the barrier level required by a product

Putting this in context is a top priority since it’s a common misconception among most brands. Not every food packaging product needs the highest achievable material barrier.

Here are some data to exemplify this food packaging myth:

A foil barrier is "highest" | .0006 |

Polyethylene (PE) (for example, bread bags) | 14-20 |

Polyethylene terephthalate/polyethylene (PET/PE) | 3 |

Because creating food packaging with a higher barrier sometimes increases manufacturers' costs, the good package for you is the one that protects your specific product under conditions it will face for the time required. The end goal, of course, is that in every package that is purchased and opened, a consumer finds a fresh and tasty product that says the best about your brand.

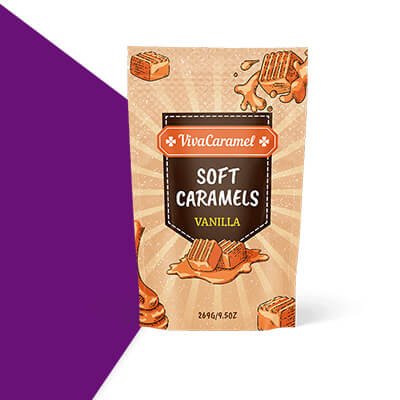

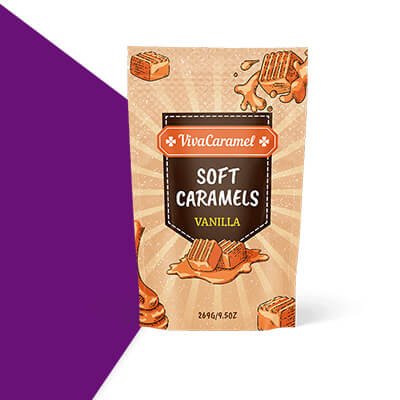

Finding a good brand design

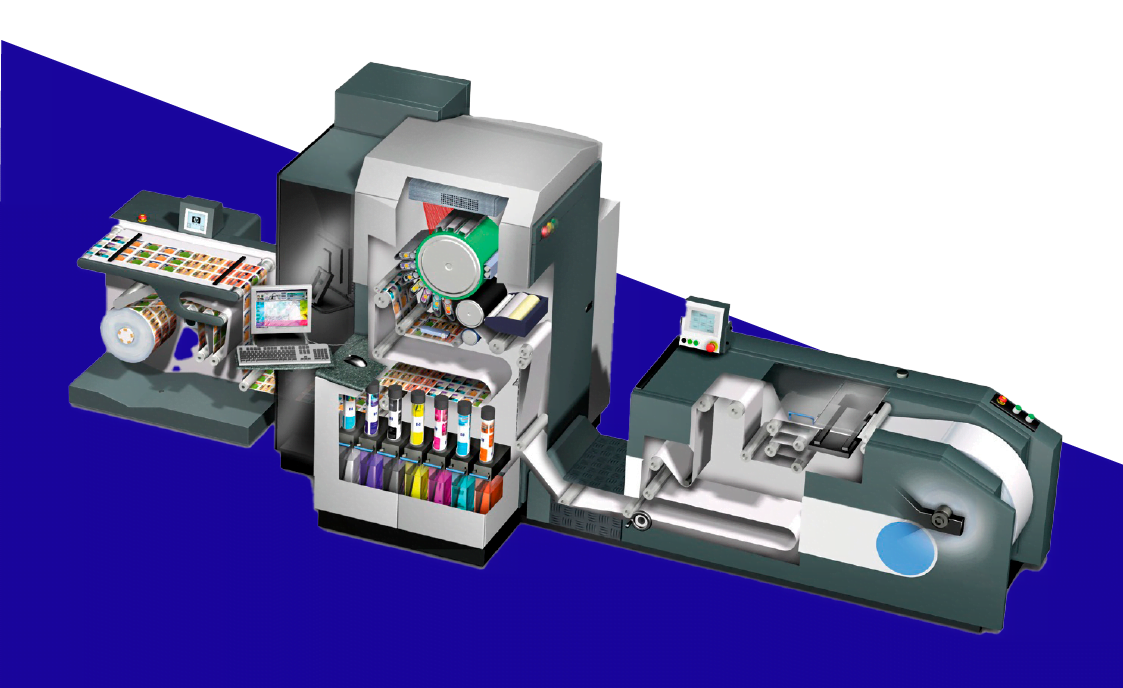

When you work with an establish brand, like Carepac, on eye catching packaging for your product, our graphics design team and manufacturers are experts and begin by understanding your business, what your product says about your food brand, how it is prepared for food packaging, how the food packages are best shipped and stored, how to help your products stand out on the shelves, and for what period of time it should be able to remain fresh at the point of purchase by your customers.

During our packaging design process, we also make sure your great food packaging design is visually appealing, has a strong food brand identity, reduces plastic waste, and incorporates the minimalistic design, environmentally friendly, branding aspects, pastel colors, or color scheme you're interested in. These important considerations and winning design elements will help your food package and brand personality stand out to your target audience, especially when compared to the brand identity of other brands in the food industry. Great packaging is what our brand and company is all about! We can help your product stand out!

Part of that process for consumable products is testing them inside bags of different materials and manufacturing. That should direct the selection of materials used with the required barrier properties but not redundantly high, which increases your budget. When there is a selection of comparable quality materials and designs, then budget considerations (and possibly your manufacturing deadline) become paramount.

At the same time, the Carepac teams addresses every aspect of your flexible packaging, such as the shape for different types of display and the crucial decision on appearance of the label. We make sure your food packaging is set in top notch condition in front of your potential customers. That is because the package and its appealing graphics are the prime point-of-purchase marketing features to close the sale. And naturally, your product's reputation with consumers for freshness is indispensable for repeat sales and word-of-mouth advertising.

Starting your Supply Chain

The first step for your business or company is as easy as visiting our website for information for your business about every phase of creating food packaging that protects the product, helps to sell it to consumers at the top point of sale, and fits your budget. Our online estimator can give you an instant price estimate for your bag as you now conceive it. The choices you will make in consultation with us, the company responsible for your design food packaging, are explained in the relevant sections of the site, with many examples to clarify your choice for your supply chain and give you a picture of what your product will look like in the store—be it brick-and-mortar or online.

When your company is ready to discuss a specific order, or ready to create one, which can begin with a planning and design session with our range of experts, just get in touch with us. And check back here to see our regular blogs where you can do some reading about consumers, challenges, opportunities, and solutions in the food packaging market.

You can visit us daily on Twitter for information, insights, and updates on what we are discussing with our customers.