No products in the cart.

Case Studies, Food Industry Packaging

Case Study: Flawlessly Fresh With Flavor

Inspired By Italy, Made in Vermont

A family tradition, a love for prosciutto, and an inspiration—say “ciao” to Vermont Salumi. This Italian-inspired meat company stands by their promise to provide cured Italian meats that are filled with flavor and freshness. In order to do this, they had to ensure their products were packaged to perfection. Here’s how we worked together with Vermont Salumi to ensure their product packing was just right.

Meet Vermont Salumi

Crafting fresh and cured Italian-style meats in the Vermont countryside, Vermont Salumi makes several savory varieties of fresh sausage, cured salami, and aged whole muscle meats.

Vermont Salumi’s Packing Needs

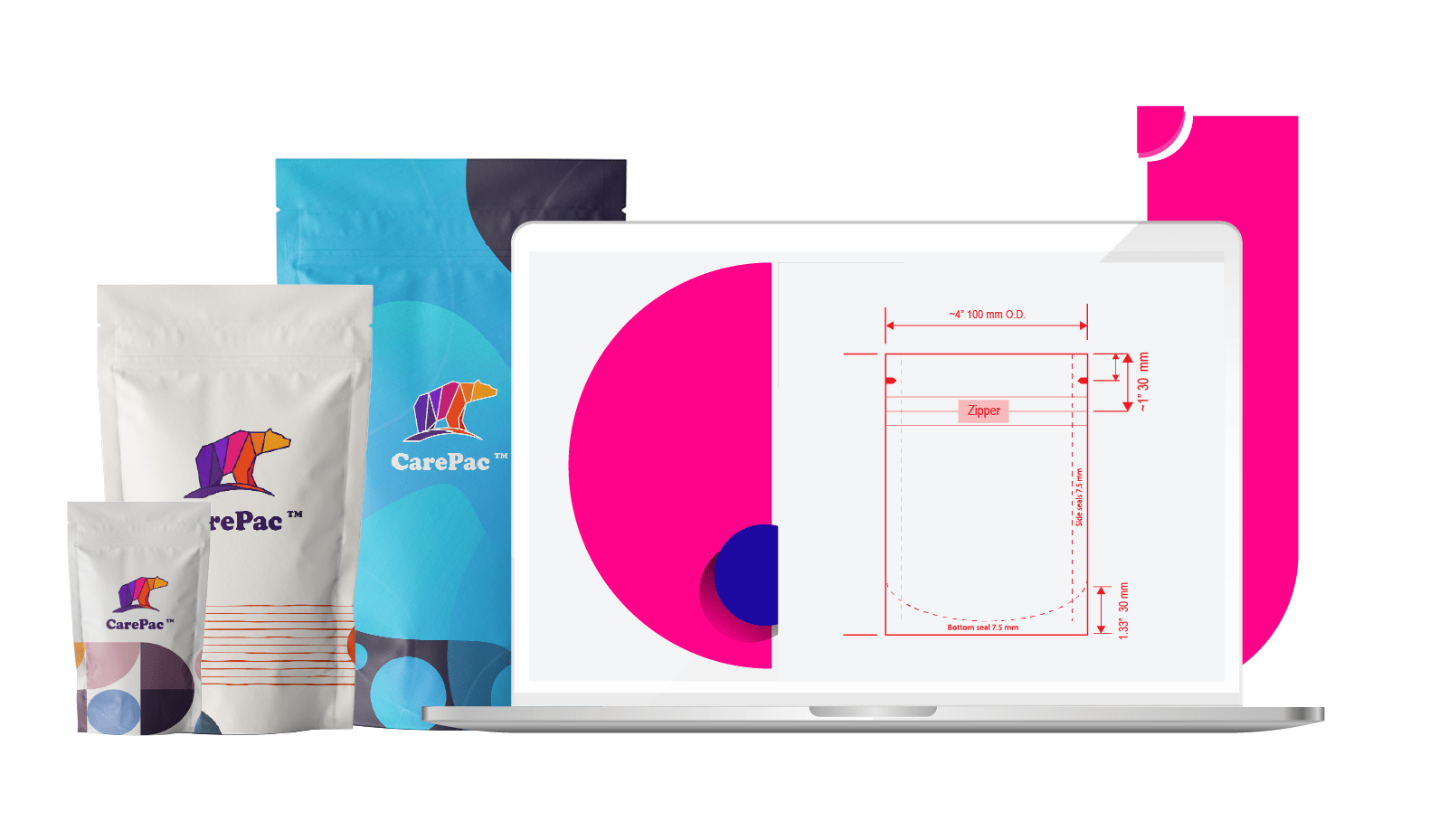

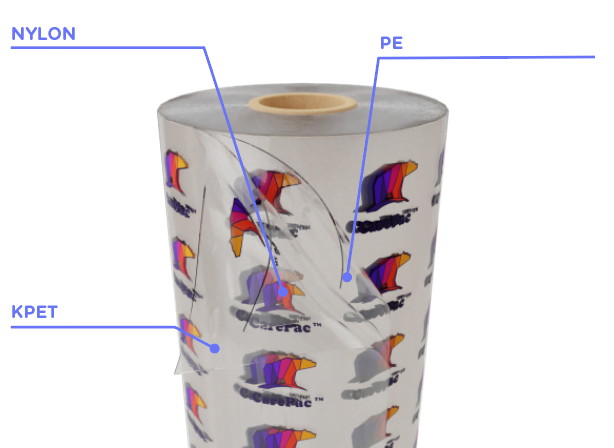

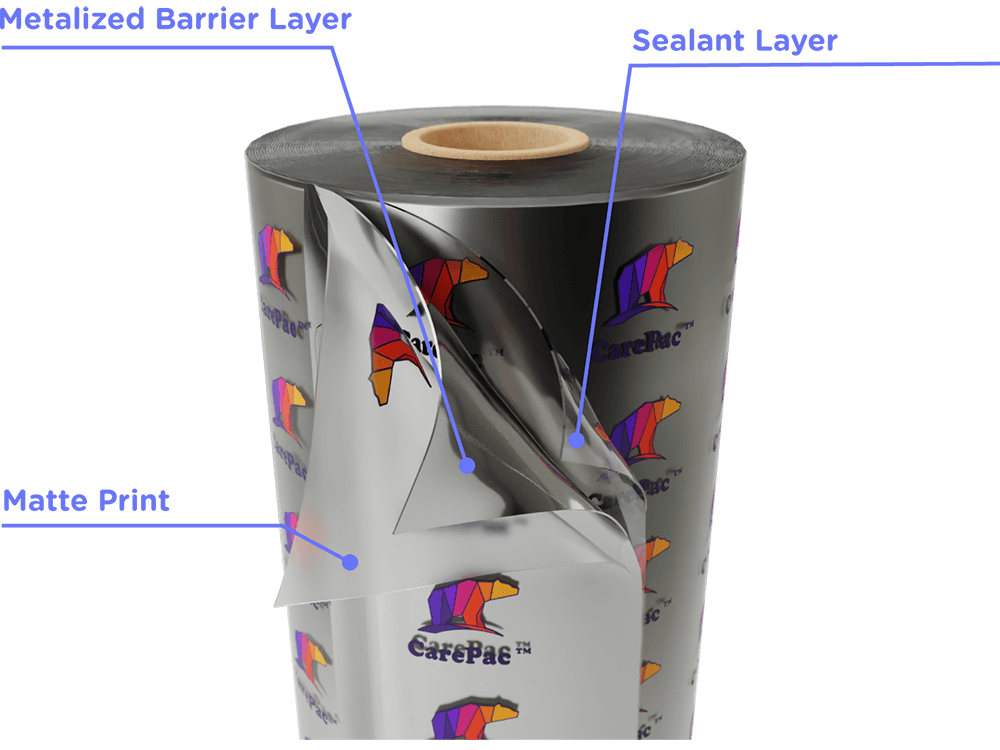

Packaging salami can be tricky, as it needs to preserve the finished aging process and flavor balance. Vermont Salumi was on the hunt to find packing options that could withstand the various storage environments their products would experience through the production channels. Additionally, it was imperative the packaging was functional—and aesthetically pleasing.

The Results

Vermont Salumi turned to CarePac to find the solution that packs the right punch for their needs. Our flexibility and customization meant that Vermont Salumi didn’t need to compromise… and the end result was the right packing, for the right price, with the right look. And the proof is in the pancetta with the new packaging, they saw an overall increase in sales and shelf life for their meats.

Have a unique packing need? Here at CarePac, we’re up for the challenge—get in touch by phone (via a real person!) or through our contact form.