No products in the cart.

How Is Commercial

Cannabis Dried - Cannabis Drying Tips

Cannabis Growing and Processing Strategies

Although cannabis growing and processing strategies vary from one facility to the next within the hemp industry, all cannabis companies have the same goal: to provide the best-quality cannabis at an affordable price. By doing so, more and more people can take advantage of cannabis’ medicinal properties without having to worry about the affordability.

One very important area of the cannabis lifecycle that’s often overlooked and doesn’t vary much between wholesalers is the drying and curing process. Whether you’re a new company in the cannabis space or a curious customer that’s wondering how their favorite cannabis strain is harvested and dried, this blog is for you. Read on to learn more about how commercial cannabis is dried before distribution.

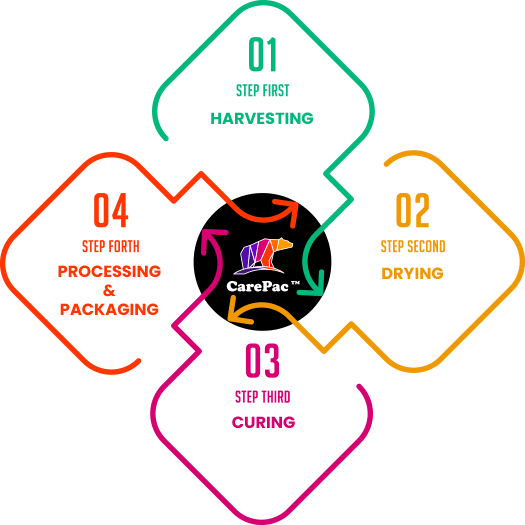

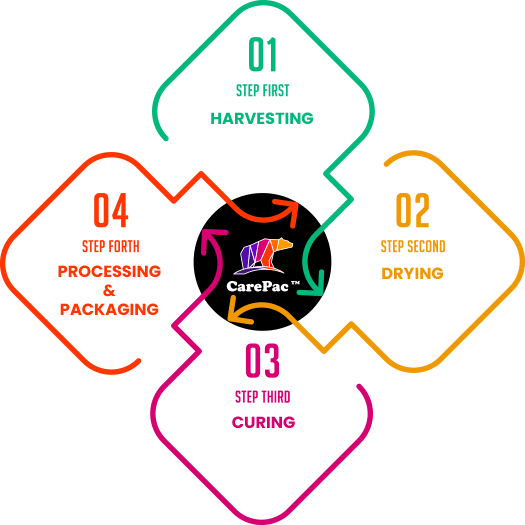

Step 1: Cannabis Grow & Harvesting

First things first is harvesting. During harvesting season, usually late September into October, cannabis farms throughout the United States begin harvesting their cannabis crops. This time of the season is often affectionately referred to as “Croptober” since it combines the words “crop” and “October.” Please note: Croptober is for sun-grown/outdoor cannabis only -- indoor cannabis can be harvested at any time, as the lighting, humidity, and other elements that promote growth can be manually adjusted.

To learn more about Croptober, check out this blog.

Step 2: Cannabis Drying

Once the cannabis is harvested, it’s time for drying cannabis on racks or bins. During cannabis drying, the initial moisture is removed from the plants via traditional drying methods. During drying, cultivators hang the whole plant or wishbone-shaped branches to dry when they've cut it down, and this is done in an environmentally controlled space. This is one of the most important, if not the most important, aspects of the cultivation process. If rushed or done incorrectly, the quality of your end product can be severely impacted. In some cases, an improper drying process can lead to cannabis that’s unusable.

When it comes to drying via traditional drying methods, the environment where drying takes place is everything. Drying always occurs indoors because cultivators must be able to control all environmental factors, from temp and humidity to light and airflow. Although most commercial growers dry their plants in 10 days or less, it’s not uncommon for drying to take as long as 21 days or as few as 5. The actual length varies less than the end product -- a properly dried cannabis plant.

Step 3: Curing

Once cultivators have completed the drying process, it’s time to move on to the next step: curing. Curing is important because, although drying does remove excess moisture, there will always be additional moisture that needs to be removed.

The curing process removes any remaining moisture, by encouraging it to move from the center of the plant toward the outside of the buds. Each grower has their own cure method, and most cultivators learn how to cure from someone on the team who has done it before.

Not only does curing involve knowing the perfect temperature and humidity levels, but it also requires special containers, equipment, and environmental monitoring. Curing has many benefits, including:

- It helps improve the taste

- It preserves and enhances terpenes and cannabinoids

- It breaks down sugars that can encourage mold growth

Ultimately, curing recreational retail hemp is important because it makes your product better, tastier, and less prone to mold.

Step 4: Processing and packaging

Once cannabis is harvested, dried, and cured, it’s time to process and package. Processing refers to getting the cannabis ready for whatever its intended purpose is -- trimmed for smokable hemp flower, ground for pre-rolls or edibles, or turned into a distillate for vape cartridges or oils. Afterward, the product is packaged for sale and distributed to dispensaries.

Cannabis Curing & Drying Process FAQs

Here are some common cannabis drying, curing, and processing FAQs.

Q. How long does cannabis need to be dried on racks?

The average drying time is about ten days, although some cultivators dry for as few as five days and others as long as 21 days. The amount of drying time doesn’t matter -- what matters is that the cannabis is properly dried before being cured, and, ultimately, processed, packaged, and sold.

Q. How long does cannabis need to be dried?

As cannabis dries, any excess moisture is released from the plant. By removing this moisture, the plant won’t attract mold or mildew and will last longer on the shelves. If you’ve ever come across moldy cannabis, this is almost always the direct result of

improperly drying and curing.

improperly drying and curing.

Q: What are the perfect conditions for drying

cannabis?

To effectively dry cannabis, there needs to be the perfect blend of lighting, humidity, and airflow. Those conditions vary from cultivator to cultivator and are adjusted depending on the moisture content of the cannabis they harvested.

Q: Can cannabis complete drying in 2 days?

No, in most cases cannabis won’t be dried in two days, and especially not faster. The industry's average is around 10 days we don’t recommend drying cannabis for anything less than five days. In some cases, it generally takes three to four weeks to properly dry and cure cannabis.

Q: Can you dry bud too long?

Yes, just like you shouldn’t dry cannabis for only two days, you shouldn’t dry cannabis for longer than a month. Like under-drying, over-drying can also cause mold to grow.

Q: Can you dry buds without hanging them?

Yes! If you prefer not to hang your buds to dry them, you can trim them and use a flat rack. Flat racks are circular and have layers of mesh, which is ideal for airflow. If you use the flat rack method, the buds should be checked every 2-3 days. Note: this method

requires that the buds be trimmed before drying.

requires that the buds be trimmed before drying.

Protect your product with the right packaging

Properly drying and curing cannabis occurs after harvest is only the first step in producing quality smokable flower and protecting cannabis from mold, mildew, and other environmental contaminants. Ensuring that you’re using the right cannabis packaging is just as important. All custom cannabis packaging should protect the cannabis within from exposure to the elements, including air and light, and should be resealable so customers can close their package and keep their cannabis fresh in between use.

For the best cannabis packaging on the market, look no further than CarePac. As a California-based company, we were an early adopter and have had time to perfect our cannabis packaging. The process is simple, our customer service team is helpful, and we offer many different sizes, styles, and bag materials. To get the process started, get an Instant Online Quote today!

Overwhelmed with

all the options?

Tags