No products in the cart.

Proofing Pouch Designs

What is Proofing?

Proofing is a preliminary version of a printed piece that shows the features and design of the final piece. It’s intended to be a confirmation of the print and bag specifications -- think of proofing like a preview or sneak peek of your project. At CarePac, our printed pouches are made to order, so before we can make your pouches, we need to make sure all pouch specifications and printing are correct.

Proofing is an essential part of the design process, as we don’t want to print pouches that don’t meet your exact expectations. We hold ourselves to a high standard, and creating the perfect bag does require some input from you. During the proofing stage, you’ll need to make sure that everything is exactly the way you want it, from the font and the logo placement to the colors and customization features. Don’t forget to check the spelling!

Why is Proofing Important?

Proofing is a critical step to ensure that the bag that CarePac is being told to make is the one you want. The last thing we want is to send you a bag that you can’t use because the size or configurations are all wrong. We recommend having multiple people on your team take a look at the proof - you never know what someone else might catch that you may have missed.

Steps of the Proofing Process at CarePac

At CarePac, we’re all about transparency, so here is what you can expect from our proofing process:

How are pouch designs proofed?

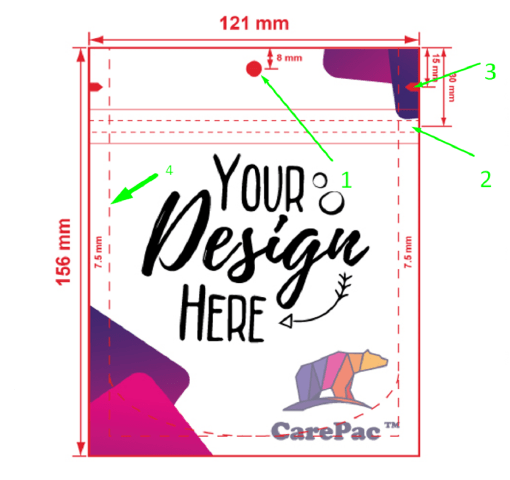

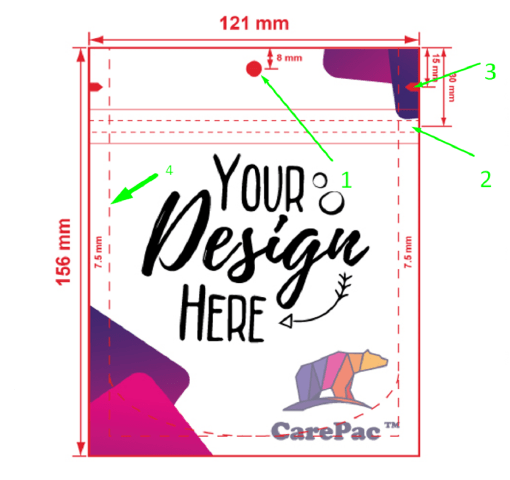

The industry standard is using digital art files to proof, which is why we’ll send you a digital proof. This type of proofing is quick and efficient and typically works perfectly well. The design schematic is a to-scale layout of the bag showing the art, color and placement of various elements on the bag, including features like zippers and tear notches.

At CarePac, we use multiple-up dielines which show the different sides of the bag individually. This format makes proofing much easier to perform, as you can see all sides of the bag. Some competitors will show you a print layout which can be harder to proof because the back of the back will be shown upside down.

In addition to text and imagery, finishes, their location and other elements will also be depicted on the design file to be reviewed. Most bag features will be depicted on the bag dieline along with relative positions.

In the picture below, we have four features:

Side Seals are where the bag material

connects together

1. Hang hole

2. Zipper

3. Tear Notch

4. Side seals

Optional Additional Proofing Steps

Occasionally some projects require additional proofing steps due to their complexity or specific concerns. There are three main types of additional proofing: Draw Downs, Film Print Proofs, and Prototyping. You can learn more about each optional and additional proofing step below.

Draw Downs

A draw down is where the color(s) used in a bag’s print design are placed by hand on the material to see how they appear on the film. Not all films can be used with draw downs because some films require additional treatment to get the ink to stick to the plastic. Draw downs are best accomplished with bags that incorporate a printed layer of paper in their makeup.

If you want to see exactly how the colors will appear on the film material, a draw down is the best (and only) way to see this. Producing a draw down does add expense (and time) to a print project, and is typically reserved for very large runs or if the ink or material is a concern. In most cases, reviewing the digital proof is satisfactory.

Optional Film print proof

This process does create some delay as we cannot schedule additional steps of the production process like laminating, curing, or bag making until the film has been approved. Please keep in mind that film print proofing can add 1-2 weeks to the production beyond normal lead-times. (This estimate assumes that you’ll review your proofs in a speedy manner.) If, after receiving the film print proof, you want to make changes, there will be some cost for the machine time, labor, and materials used to produce the film print proof. This varies by the type of printing being used, and the complexity of the printing.

With film print proofs, after the design file is approved, we perform the actual printing of the material but then stop and send a cut-off of that film to you for review.

With a film print proof, you can see the actual print on the material that will be used to make your bags. Once you approve the film, then we will continue on with the production of the bags.

Optional Prototyping

For the ultimate in proofing, we offer CarePac Express. With CarePac Express, we offer very small quantities, as few as 100 bags, which can be made to your specifications and are fully completed bags.

Digital Proofing

is Included!

Although draw downs, film print proofs, and CarePac Express all incur an additional cost, standard digital proofing is included in our pricing models. If you need help understanding a digital proof or have any questions whatsoever about our proofing options, please don’t hesitate to reach out to your representative. For an instant online quote for your project, please click here.

Tags