No products in the cart.

Data Sheets

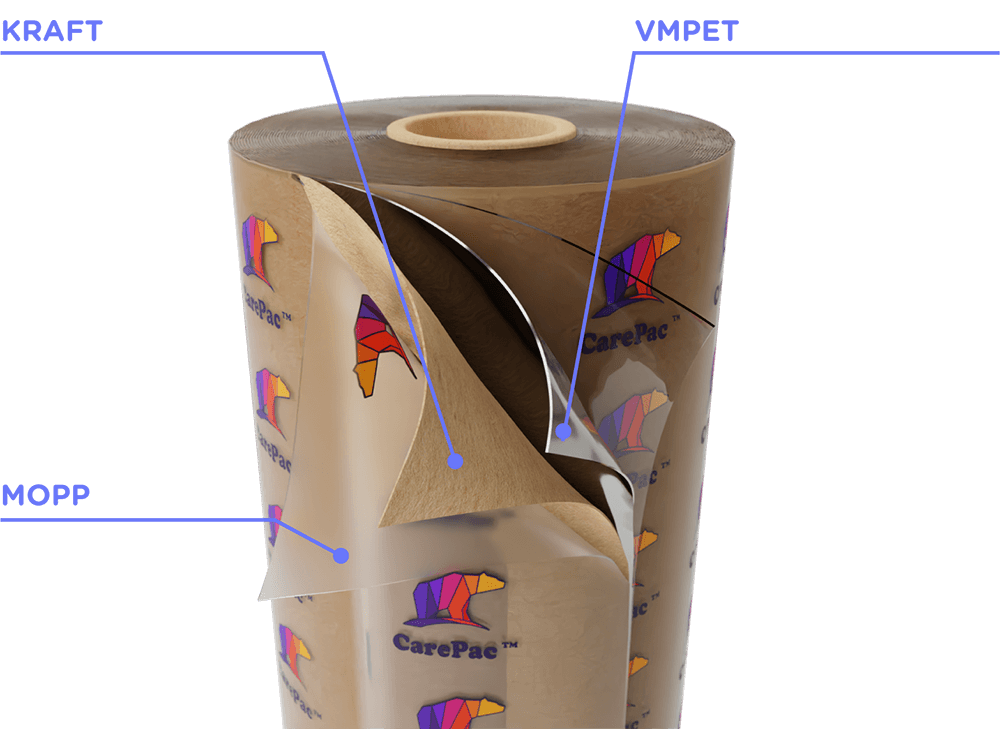

CareKraft-KP

CareKraft-KP

Overview

This FDA approved film does not stretch due to the orientation of the layers during the lamination process. Great for Food and industrial uses, The kraft paper can be either White or Brown kraft and is combined with a heat sealable PE liner. This is a low barrier product which is best suited for shelf stable products that do not require high barrier packaging to extend its shelf life.

Note: The performance of any film will be influenced by a number of factors and testing must always be performed to ensure the film meets the use.

Relative Performance Indications

Oxygen Barrier

Moisture Barrier

Light Barrier

STrength

Heat Resistance

Freezer Storage

Material Data

Here are some of the common indicated properties for this film.

ITEM | UNITS | ACCEPTABLE LIMIT | RESULTS | ITEM CONCLUSION |

|---|---|---|---|---|

Thickness Deviation | % | ±10 | +1.4~ +8.6 | Pass |

Length Deviation | mm | length 101~400;±3.0 | -1.0~0 | Pass |

Width Deviation | mm | width 101~400;±3.0 | -1.0 | Pass |

Width Deviation for heat seal | mm | seal width 5~10;±1.5 | 0~+1.0 | Pass |

Tensile Strength | N | ≥40 | Longitudina:6 Landscape:61 | Pass |

Breaking Elongation | % | ≥5 | Longitudina:161 Landscape:97 | Pass |

Right angle tearing force | N | ≥3.5 | Longitudina:13.8 Landscape:13.5 | Pass |

Interlayer peeling force | N | ≥2.5 | Longitudina:8.8 Landscape:9.3 | Pass |

Sealing force | N | ≥20 | Longitudina:30.5 Landscape:29.5 | Pass |

Anti-pendulum impact energy | J | ≥20 | 1.92 | Pass |

Water vapor transmission(WVTR 38 ﹾC @90%RH) | g/(㎡·24h) | >0.8 | 5.8 | Pass |

Oxygen transmission(OTR 23 ﹾC @50% RH) | ㎝³/(㎡·24h·0.1MPa) | ≤12 | 47 | Pass |

Heat resistance | --- | ≤50 | Meet the standards | Pass |

Cold resistance | % | No significant deformation,layered,cracking | 96 | Pass |

Oil resistance | % | ≥60 | Tensile force change rate:0.87 Elongation force change rate:7.1 | Pass |

Pressure resistance | --- | Take 5 bags filled with similar contents 140g and seal them one by one on the smooth contact surface, the area is larger than the sample between the splints, load 400N to maintain 1min, the bag should be no leakage, no rupture. | Meet the standards | Pass |

Drop performance | --- | Take 5 bags filled with similar content 140g, drop height of 500mm, the bag will fall in the horizontal and vertical direction once, the bag should be no leakage, no rupture. | Meet the standards | Pass |

Sensory Index;Exterior | --- | Flat, no wrinkles, good edge seal, no cracks, separation of pores and composite layers. | Meet the standards | Pass |

Sensory Index;Bag soaking solution | --- | No odor,turbidity and discoloration. | Meet the standards | Pass |

Evaporation residue;65% Acetic acid,60℃,2h | mg/L | ≤30 | 12 | Pass |

Evaporation residue;65% Ethanol,Normal temperature,2h | mg/L | ≤30 | 6.5 | Pass |

Evaporation residue;Ethane,Normal temperature,2h | mg/L | ≤30 | 3.2 | Pass |

Potassium permanganate consumption(Water),60℃,2h | mg/L | ≤10 | 0.31 | Pass |

Heavy metal(Pb)4% Acetic acid,60℃,2h | mg/L | ≤1 | <1 | Pass |

Toluene diamine(4% Acetic acid)60℃,2h | mg/L | ≤0.004 | Not detected | Pass |

Density at 23℃ | g/cm3 | 0.85-1.00 | Meet the standards | Pass |

FDA 21 CFR 177.1520- Extractable fraction in n-hexane and soluble fraction in xylene | ||||

Test Requested: | As specified for client, to determine Extractable fraction in n-hexane and soluble fraction in xylene for compliance with the Food and Drug Administration Regulations for polypropylene and polyethylene used in contact with food | |||

Test Method: | With reference to FDA 21 CFR 177.1520. | |||

Extractable fraction in n-hexane at 50℃ | w/w% | 1.5 | <0.6 | PASS |

Soluble fraction in xylene at 25℃ | w/w% | 3.3 | 10.9 | PASS |

All values indicated regarding film properties or characteristics, were provided by our film supplier and are given as an indication and should be considered as average indicative values. This document is based on our film supplier statements and / or independent lab testing, data from multiple tests, or different film suppliers of the same film family may be combined in the above table. While unexpected, it is possible that the validity of the statements could change without notice.

Environmental Impact

This material is a multi-layer laminated plastic and will typically fall into the check-locally, or store drop off category.

Property | Sample Data |

|---|---|

Recyclable | Multi-Layer Check Locally |

PCR Option Available | Yes |

At Home Compostable | No |

Commercial / Industrial Compostable | No |

Recyclability and composability varies by jurisdiction. Composability claims are limited by law, and vary by jurisdiction, consult a qualified professional in your state.

Compliance

Compliance is important, and here are CarePac we can support your compliance needs with extensive film supplier and lab testing data.

BPA FREE

FDA Food Approved

PROP 65

Property | Sample Data |

|---|---|

CEPE/EuPIA | Manufactured in accordance with |

Cal. H&S (25214.16) | Compliant |

PFAS - perfluoroalkyl and polyfluoroalkyl § 37-0209, RCW 70A.222.070 | Does not knowingly add |

Prop 65 (OEHHA) | Does not contain listed substances |

SR 817.023.021 | Not in excess of overall or specific migration |

EU directive 10/2011/ED | Compliant |

EU directive 1935/2004 | Compliant |

FDA 21 CFR 73 | Compliant |

Cal. H&S (25214.16) | Compliant |

RoHS Directive 2011/65/EU | PASS |

Compliance information above is derived from lab testing, or film supplier statements. Independent verification is advised, and Lot specific testing available.

Related Materials

This material has high barrier to moisture vapor and oxygen but low physical strength and the unprocessed paper exterior can crack and crinkle, and tear easily, and must be handled and stored with more care than a plastic product. The natural paper exterior is subject to natural variations in color, texture, and all visual elements between each lot.

CareKraft-KAP

The brown natural Kraft exterior makes the structure rigid, but it tears easily in both directions. The foil provides excellent barrier to extend shelf life and protect the taste profile. The polyethylene sealant layer is extruded brown to mask the color of the foil. This unique design element makes the PF500 BRN a good fit for customers that do not want to see foil in their packaging but need the protection that it exhibits.