No products in the cart.

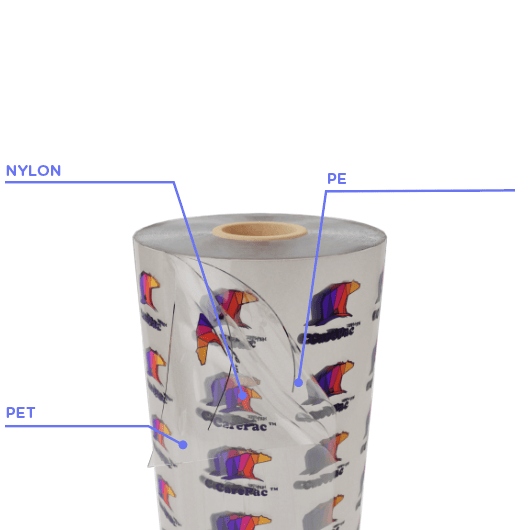

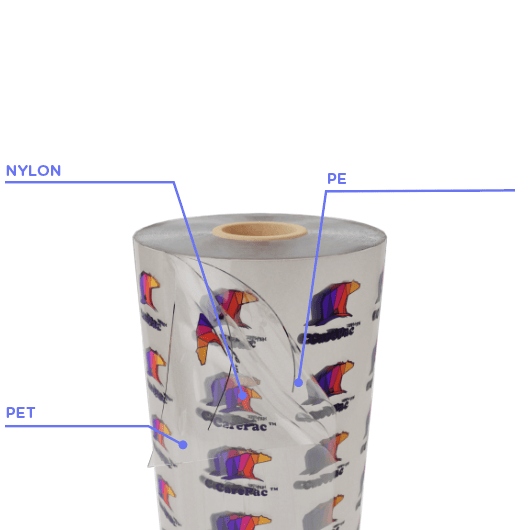

CareClear-XP (XPET/PE)

PET is by far an excellent packaging material due to its high oxygen barrier, durability, and heat resistance. It’s also known for being a great laminating substrate. Many products need enhanced barriers as their packaging materials, which can be achieved with lamination and/or coating. PET coated with PVCD (Polyvinylidene chloride) results in a laminate called KPET or saran coated PET, which offers higher moisture and gas protection.

Barrier Properties

KPET/PE is used when you are seeking to combine enhanced barriers with a transparent appearance. Packaging that allows the consumer to see inside the bag is very attractive, especially for food products. Beautifully designed pouches draw the customer, but having a clear view of the delicious item you are buying is even more appealing.

Note: The performance of any film will be influenced by a number of factors and testing must always be performed to ensure the film meets the use.

Relative Performance Indications

Oxygen Barrier

Moisture Barrier

Light Barrier

STrength

Heat Resistance

Freezer Storage

Customer Profile

KPET/PE was a good packaging solution for this customer.

Granola producers face stiff competition. In this application the customer wanted to extend the shelf life by increasing the OTR barrier of the pouch. In this instance they also wanted the product to be visible to the consumer. CareClear-XP was a good choice for this use.

Film Material Specifications

High barrier, chemical stability, protection against vapor and oxygen are features that make the KPET/PE film an excellent packaging solution for food, pharmaceutical, and medical items. Vitamins can lose their benefits due to moisture and oxidation. Food can go stale. In other words, sensitive products that need to endure an extensive shelf life with their properties unharmed go well with this packaging film.

Here are some of the common indicated properties for this KPET/PE film

Property | Sample Data |

|---|---|

Available Thicknesses | 2mil - 8mil |

Sample Data Thickness | 4 mil |

MVTR | 0.2 Mocon |

OTR | 0.4 1434-66 |

Tensile Strength | >42 TD, >42 MD ASTM D 882 |

Elongation at Break | >55 MD, >50 TD ASTM D 882 |

Heat Seal Strength | >6 Kg/15mm |

Bond Strength | >500 KPET/PE in g/15mm |

COMPRESSIVE STRENGTH | 80-600 JIS Z 0238 |

Does PVDC improve OTR or MVTR more?

One of the main goals of packaging is to increase the shelf life while keeping the product fresh. Oxygen and vapor are villains in this case that must be left outside.

Depending on the type of product you are packaging and how sensitive it is to oxidation and moisture, you need to be aware of two key parameters: OTR and MVTR.

Oxygen transfer rate (OTR) is the amount of oxygen that passes through the film in 24 hours, while MVTR stands for moisture vapor transfer rate. For both rates, a lower number indicates higher barriers.

Foil presents the best OTR and MVTR barrier with near zero transmission rates. Its downsides are cost and susceptibility to pinholes.

When comparing OTRs, Metalized Polyester (METPET) offer better protection against oxidation than KPET. On the other hand, when we look at MVTRs, METPET has the highest barrier (1.2) than KPET (7.55), EVOH (100), and Nylon (260) in a single layer thickness of approximate 14 microns.

Although METPET presents the best rates, it’s important to remember that this is a metalized material. Its opaque appearance prevents the product from being visible through the package. So if you seek a clear material to show the look of your product to your customers while having excellent barrier properties, KPET is the one to go.

Environmental Impact of Our Bags

This material is a multi-layer laminated plastic and will typically fall into the check-locally, or store drop off category. The product is

Recyclability

Industrial Compost

Compliance Information For Our Custom Bags

With years of experience in the packaging market, we know how to deliver superior quality and exceptional customer service whether you’re a startup business working on your first custom bags or if you’re an established business looking for a reliable supplier.

Kosher

BPA FREE

FDA Food Approved

EU Food Approved

PROP 65

RoHS / R.E.A.C.H

Common Uses - Stand Up to Flat Bags

What are the applications for the KPET/PE film? This material is used for packaging tea, pasta, cakes, snacks, oily and fried foods, meat, dairy, spices, iodized salt, medicine, and chemical products.

KPET/PE is a flexible material that can be manipulated into any type of pouch you desire, from stand up to flat bags.

It’s a fully printable film, and it works great with both types of printing we provide:

- Digital printing – great for low quantity production runs or where there are many sku variations.

- Plate printing - Offers the lowest cost per unit, making it an excellent choice for wholesale.

It allows you to add many features and seals as hang hole, tear notch, zippers, spouts.

This material is also a base film for soft touching if you want to add that velvety touch and luxurious matte finish to your packaging that will impress your customer’s senses.

If you need any help with your packaging design, you can contact our design specialists, and they will understand your product and brand’s needs and find the best solution for you.

Snacks & Chips

Chips, Wafers, Nuts, Popcorn, Seeds, Trail Mix

Cannabis

Cannabis, extracts, edibles, marijuana

Frozen Foods

Frozen Vegetables, and frozen meals.

Cookies & Candy

Biscuits, Cookies, Chocolate Bars, Candy, Chewing Gum

Frozen Foods

Vegetables, Seafoods, Meat, Block Cheese

Agricultural

Plant Seeds and Plant Fertilizer

Spices & Flour

Spices, Flour, Salt, Sugar, Rice, Papad, Baking Mix

Dog & Cat Food

Dog & Cat Food, Bird Seed, Livestock Feed

Chemicals

Agro Chemicals, Detergent, Industrial Chemicals, Cement

Powder Product

Protein Drinks, Milk Powder, Supplementary Powder

Personal Care

Incense Sticks, Cosmetics, Wet Wipes

Are KPET/PE Bags For You?

For products that :

-require a high barrier;

-are susceptible to oxidation and moisture;

-need odor protection;

-have chemical compounds;

-and goes well with a clear transparent packaging look;

This is definitely the material for you.

Component Details

KPET/PE is a two-layered transparent material with an enhanced barrier provided by the PVDC coating on the PET layer.

How does PVDC coating improve the gas and moisture barrier?

PVDC is produced by polymerizing vinylidene chloride, resulting in clear and flexible plastic with outstanding oxygen and moisture barrier compared to metalized films.

It also has high chemical resistance and inertness, preventing odor formation and interaction with the product inside the packaging.

Since it’s a more expensive component, it’s often mixed with less costly materials to combine its benefits with more feasible costs.

Related Materials

CareClear-PNR PET/Nylon/RCPP

This material is best when used with a high heat liquid such as spout pouches or high heat retort and microwave meals .

CareClear-PP PET/PE

Economical general use where a mid-range quality barrier is needed.

CareClear-PNP PET/NYLON/PE

Enhanced strength and MVTR barrier.

Tags