No products in the cart.

What are Barrier Bags?

Barrier bags are plastic bags designed to protect their contents from moisture, dirt, oxygen, light, and other contaminants. They’re often made with heavy duty plastic materials and liners that have puncture and smell-proof properties and, depending on what’s inside, our barrier bags can also be produced with child-resistant properties. Some gusseted bags are made for specific industries, like the coffee or cannabis industries, while others are broad enough for general use across many industries.

At CarePac, we live and breathe barrier bags and are dedicated to helping you design the best barrier bags and pouches for your needs. Whether you require a flat pouch, custom paper, zippers, clear plastic packaging, or unique fabric you can find just what you’re looking for right here.

Types of Barrier Bags & Packaging

CarePac is in the business of barrier bags, so virtually everything we sell on our site is considered a barrier bag. Some of the most common types of barrier bags include:

Each of our different barrier bags can be custom ordered and are sold at bulk price. Our precision machinery ensures your bags will be uniform in size, from oz to lbs and everything in between. We offer the highest quality barrier bags on the market, with the absolute best customer services. Plus, we have a 5% price match guarantee.

What are you waiting for? Start a custom order today.

What are the Best Barrier Pouches for Me?

Many customers are curious about which barrier material and bag type is best for their unique situation.

Below you’ll find some common uses for our pouch bags, along with our recommended barrier material and bag type. But remember: with over 50 materials to choose from, including aluminum and metallized materials, our custom barrier bags can be customized down to the sizing, material laminations, and material thicknesses.

Item | Barrier Material | Bag Types |

|---|---|---|

Granola, rice, etc | Polyethylene terephthalate | Gusseted Pouches or flat pouch |

Liquids | Polyethylene, Nylon, and Aluminum | Stand-Up Pouch with Spout |

Protein Powders | Polyethylene Aluminum | Zipper pouch bags |

Hot Fill Foods | Polypropylene CPP/RCPP | Flat Pouch or stand up pouch |

Coffee | Metalized Polyethylene or PET/ALU | Box Bottom Bag, Side Gusseted bags |

Pick Your Configuration

Most of our barrier bags and stand-up food pouches are made with clear poly plastics so the customer can view the products inside, but all of them are available in opaque or colored configurations. The clear bags can also be configured with zippers and gusseted features.

Get in touch with us to begin a custom project.

What are the Different Barrier Pouch Bag & Boxes Materials?

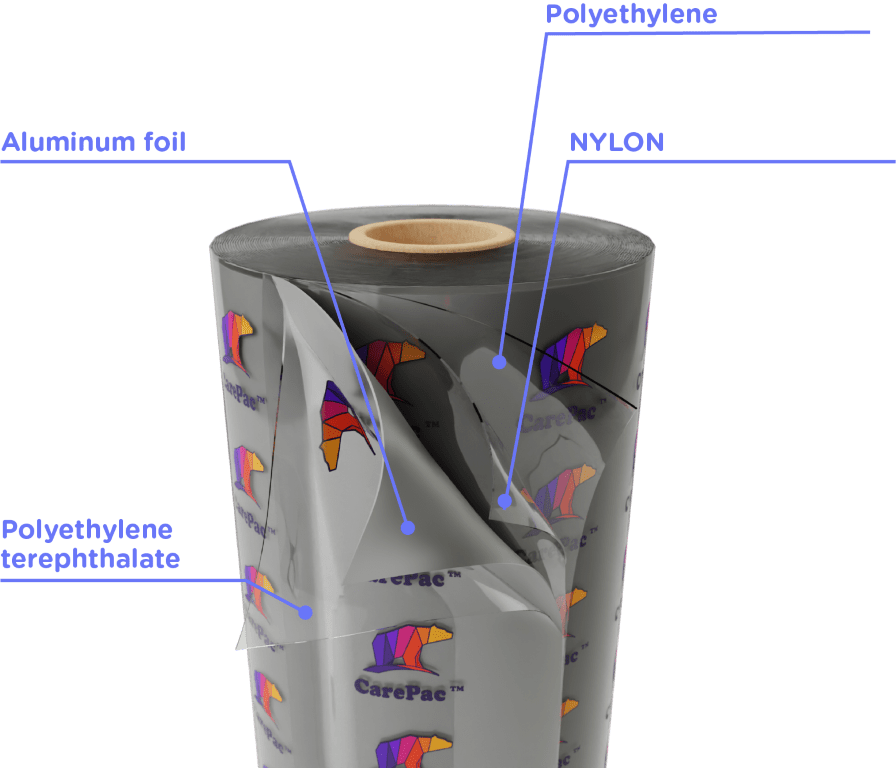

Barrier pouches are generally made from the lamination of various materials to provide a different barrier

Characteristics. Which material you choose for your gusseted bags ultimately depends on what the bags will be used for.

Barrier Pouch Material | Barrier Potential Barrier Potential | Notes |

|---|---|---|

Polyethylene | Low | By itself Polyethylene (PE) has a low barrier. |

Polypropylene | Low | Much like Polyethylene polypropylene is a low barrier. |

Polyethylene terephthalate | Medium | The start of high barrier materials is PET, it provides a robust barrier when laminated to PE. |

Metalized Polyethylene terephthalate | Medium | Barrier pouches that utilized METPET have a strong economic barrier. |

PVDC coating PET | Medium | Increased OTR barrier |

Nylon | High for H2O | Better Water barrier and enhanced strength. |

Aluminum foil | Very High | Aluminum foil providers a very high barrier to both oxygen and moisture |

Barrier Pouch FAQs: Questions About Barrier Pouches

See below for some questions we’re frequently asked about our barrier and zipper pouch bags. Ready to buy? Reach out to us for more information.

What thicknesses do barrier bags come in?

Barrier bags can be made as thin as 2 mil and as thick as 13 mil, but for commercial use the thickest material usually is 8 mil. Most barrier bags do not need to be anywhere near 8 mil single edge thickness. Typically 4 mil – 5 mil is sufficient for most uses.

What barrier material should I choose for my barrier bag?

This is a question that will relate to what you are using the bag for. Is this long-term storage? Hot fill bags? Retort pouches? It really comes down to what is best for your use. For the highest barrier you’ll want an aluminum pouch. For high strength and tear resistances, add nylon. For high temperature (boil in bag) change to RCPP materials.

What is the most heavy-duty barrier bag available?

From a strength standpoint, a multi-laminated 7 mil barrier bag made from Polyethylene terephthalate 2 with layers of Biax Nylon, Vapor Metalized Pet, and Strength PE would provide an extremely strong bag. For very extreme uses a barrier bag could be made with Scrim, foil, and poly in a range of thickness greater than 10mil.

From a barrier standpoint (moisture and oxygen) a bag that combines Nylon, PVDC, Aluminum, and strength PE, would be best. Finally from a heat standpoint a bag that uses CPP/RCPP would withstand high temperatures well above boiling.

Are barrier pouches made of fabric?

No, barrier pouches are made of non-woven fibers and plastics.

How do you seal barrier pouches?

Barrier bags are generally heat sealed using an impulse heat sealer or band sealer. Depending on the number of pieces you have to seal, an impulse hand sealer is great for small quantities, whereas a semi automatic band sealer is a good choice when you have many bags to seal. The price for barrier pouch sealers ranges from inexpensive impulse sealers, which cost $50, up to high speed gas flushing band sealers which can be north of $5,000.

What type of matte barrier bags are available?

Many barrier materials like PET and MET are generally glossy by default. Matte barrier bags can be made using various methods. Firstly, any barrier bag with an actual aluminum foil layer can have the aluminum foil matte edge facing out, to create a matte look. Alternatively, matte barrier bags are available that use either a matte lamination such as Matte OPP, or a matte varnish which creates a matte look. Finally there are new matte coatings such as soft touch, luxefilms karess, and Ultramatte.

What configuration of barrier pouch has the best shelf life?

From a viewpoint of barrier, the simpler the pouch the better. Think of MREs (meals ready to eat), they are usually simple flat pouches with only a tear notch. This allows the seals to be super strong, and since there is less complexity to the pouch itself you get a strong, long lasting pouch. With that said, with the advancements in bag making technology and machining, we can now even store liquids in spouted gusseted pouches. .

What plastic barrier pouch is better: a clear pouch or an opaque barrier pouch?

Generally an opaque pouch that includes METPET or Aluminum will have the higher barrier. But many times being able to see the item inside the barrier pouches, using a clear oval or rectangular window, requires the use of a clear material. Clear pouches, when made of high barrier clear materials like KPET, can have a very strong barrier while still allowing for the viewing window.

Are barrier pouches a good alternative to cans?

Yes, a barrier pouch can provide similar shelf life for many uses, depending on the item or supplies being packaged. The addition of aluminum foil to the barrier zipper pouch creates what is, in essence, a flexible aluminum can.

The CarePac Guarantee

Still not sure? CarePac focuses exclusively on barrier bags and custom packaging for a variety of industries, from cannabis wholesalers to food and beverage distributors. We have exceptional customer service reps who are committed to making sure your order bundle is completed to perfection. With our CareDesign® process you can rest assured that your barrier pouches will be done right, no matter what.

From nailing down the right colors to making sure the logo is in the right place, we understand you put a lot of time into perfecting the look and feel of your product packaging. With vivid colors, quick printing, and a variety of materials to choose from, we have the tools, the technology, and the expertise to make your project a reality. Ready to experience the CarePac difference? We think now is the right time to give us a try.