-

×

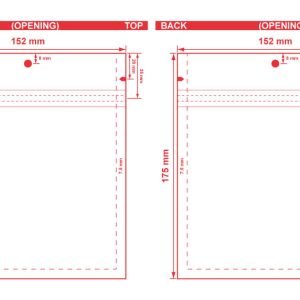

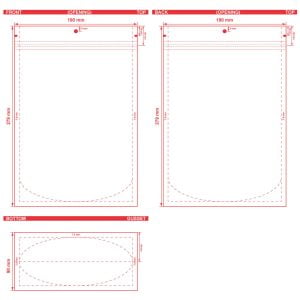

Custom Stand-Up Pouch 8.125x10x3.5 Dieline

1 × $0.00

Custom Stand-Up Pouch 8.125x10x3.5 Dieline

1 × $0.00 -

×

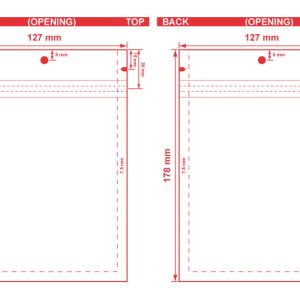

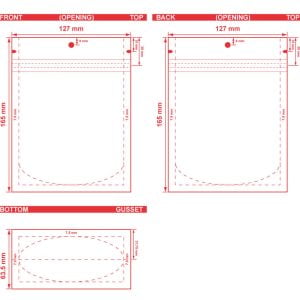

Custom Stand-Up Pouch 5x6.5x2.5 Dieline

1 × $0.00

Custom Stand-Up Pouch 5x6.5x2.5 Dieline

1 × $0.00 -

×

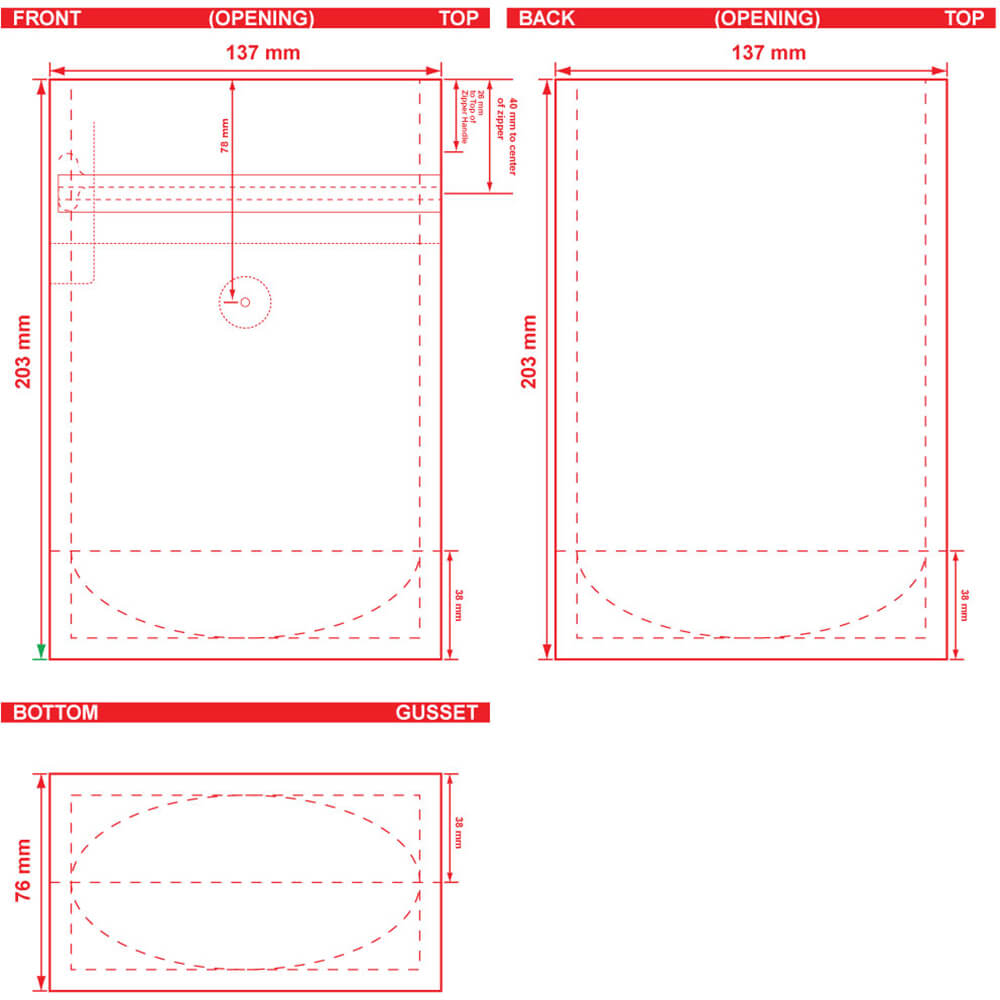

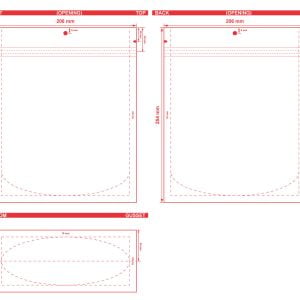

Custom Printed Stand Up Pouch 10x10.5x3 Dieline

1 × $0.00

Custom Printed Stand Up Pouch 10x10.5x3 Dieline

1 × $0.00

Subtotal: $0.00