No products in the cart.

MIL-PRF 81705 Packaging

MIL-PRF 81705: Materials Available

If the military relies on it to protect essential electronic components on the battlefield, it absolutely must be the best of the best. In fact, CarePac’sa MIL-PRF 81705 T1 material is included

MIL-PRF 81705 FR 2194 or CadPak-ESD are great options. With excellent ESD protection, moisture and oxygen barrier, strength, durability, and corrosion resistance, MIL-PRF 81705 film is the perfect choice for making Mil-DTL 117 T1 CF S1 pouches. This material can also be converted into sheeting, tubing, and 2-seal pouches with Faraday Cage.

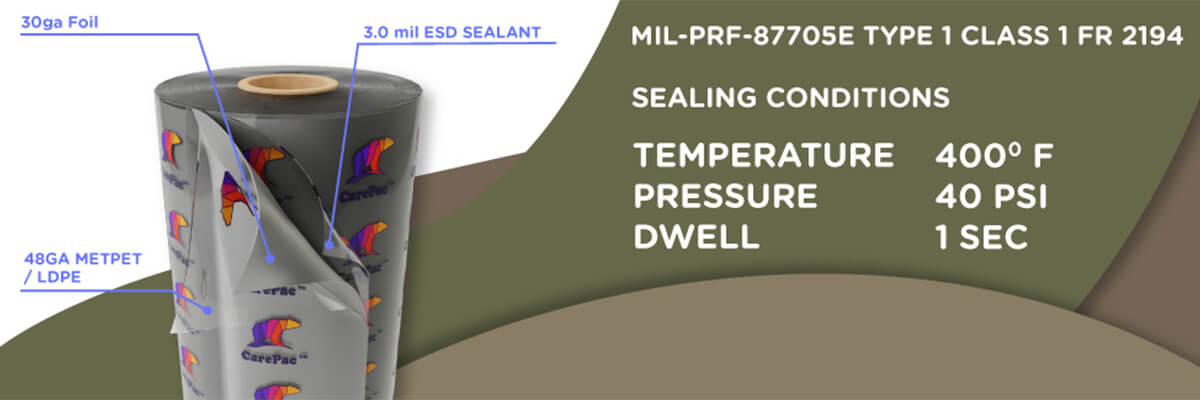

CadPak-ESD

CadPak-ESD is a Foil based material which uses an interior 3 mil ESD Sealant layer. By incorporating Foil into the lamination this film has a very low MVTR and OTR. This film is designed to provide permanent electrostatic protection, and attenuates electromagnetic radiation. CadPack-ESD provides a electro mstatic shielding of 0.45 Volts under EIA-541 testing and EMI attenuation of between 30 and 35 db.

FR 2194

FR2194 is slightly thinner materials than CadPak-ESD using antistatic METPET exterior and a interior Nucrel liner. Performance characteristics are similar for MVTR and OTR and EMI attenuation of 38 under EIA-541

MIL-PRF 81705: Materials Available

Property | Method | Unit | Common Value |

|---|---|---|---|

Surface resistivity | ASTM-257 | Ohms/Sq/ Outer | 10^3 |

Surface resistivity | ASTM-257 | Ohms/Sq/ Outer | 10^7 |

EMI Attenuation | MIL B-81705 | dB | 38.8 |

Static Shielding | ELA-541 | Volts | -2 +3V |

Though we do our best to adhere to MIL-PRF 81705 and other military standards, we encourage all current and future customers to review the specifications in-depth before designing or purchasing packaging that uses MIL-PRF 81705 materials.

There is no one-size-fits-all solution for packaging sensitive electronic components, especially if you’re packaging, handling, or transporting electronic components or electronic devices for the Army, Navy, Air Force, or any other branch of the military.

Not only does the packaging need to protect the electronic components inside from exposure to the elements and other environmental hazards, but it must meet very specific specifications outlined by the Department of Defense in their Department of Defense Index of Specifications and Standards (DoDISS). One of those standards is MIL-PRF 81705.

What is MIL-PRF 81705?

Although the pouch specifications will vary depending on the specific needs of the application, such as the size of the item being packaged, it’s important to note that all materials used to package electronic components for the military must adhere to MIL-PRF 81705. These materials and packaging can include conductive bags, static shielding bags, and other types of protective materials intended to prevent electronic components and assemblies from damage.

These specifications refer specifically to electrostatic discharge (ESD) shielding and protection materials, meaning that if the packaging is compliant with MIL-PRF 81705, the electronic components within the packaging will be protected from electrostatic discharge, among other environmental hazards, during handling, transportation, and storage.

MIL-PRF 81705 is just one of many performance specifications, and this one focuses specifically on protecting electronic components from ESD and exposure to oxygen and moisture. Other important specifications to note include MIL-DTL-117, MIL-PRF 131 and MLF-PRF 121, among others.

What are the benefits of MIL-PRF 81705?

The most important advantage of adhering to MIL-PRF 81705 is that these packaging materials will comply with the specifications set forth by the military. Anything you purchase that uses MIL-PRF 81705 materials will prevent electrostatic discharge, which can damage sensitive electronic components, and will be accepted by any branch of the military.

Additionally, there are some other benefits to note:

ESD protection: To prevent electrostatic discharge (ESD), which can damage sensitive electronic components.

Moisture and oxygen barrier: Which helps to protect components from corrosion and oxidation.

Corrosion resistant: Which helps to protect components from damage in humid or corrosive environments.

MIL-PRF 81705 film is designed to be a strong and durable material that can withstand harsh environments.

Puncture and tear resistant: MIL-PRF 81705 requires a biaxial orientation of the film layers to increase puncture and tear resistance.

Although the military requires MIL-PRF 81705, many non-military commercial companies adhere to the standard as it provides the great protection against environmental hazards.

CarePac: A Partner You Can Trust

MIL-PRF 91705 is a military specification that outlines the requirements for packaging electronic components for the military. The standard sets requirements for the construction, strength, durability, and environmental protection provided by the packaging materials, particularly in regards to protecting the components from electrostatic discharge.

With decades of experience in the packaging industry, CarePac is a partner you can trust. We’re familiar with and experienced with providing packaging for sensitive industries and applications, including the military. Have questions? Contact our team today to discuss your project. Ready to get started? Get an Instant Quote!