No products in the cart.

What is an eye mark

Did you ever look at a product packet and noticed different kinds of information and markings on it and wondered why are they here?

These marks called “eye marks” are present for specific reasons. Though they are not important for the customers in general, they are very important for the manufacturer during the packaging stage.

These markings are sometimes referred to as eye spots.

What is an eye mark?

While it might be a common practice in the packaging industry to talk about an eye spot, it certainly confuses and raises different questions for someone unknown to the term.

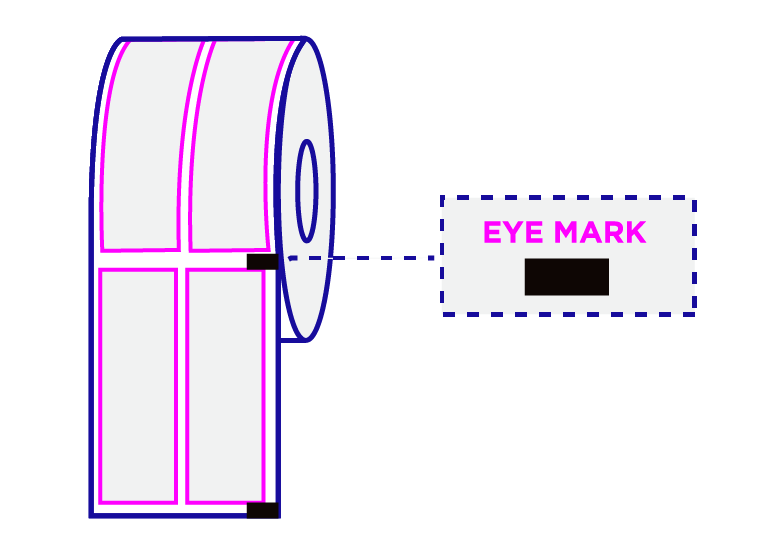

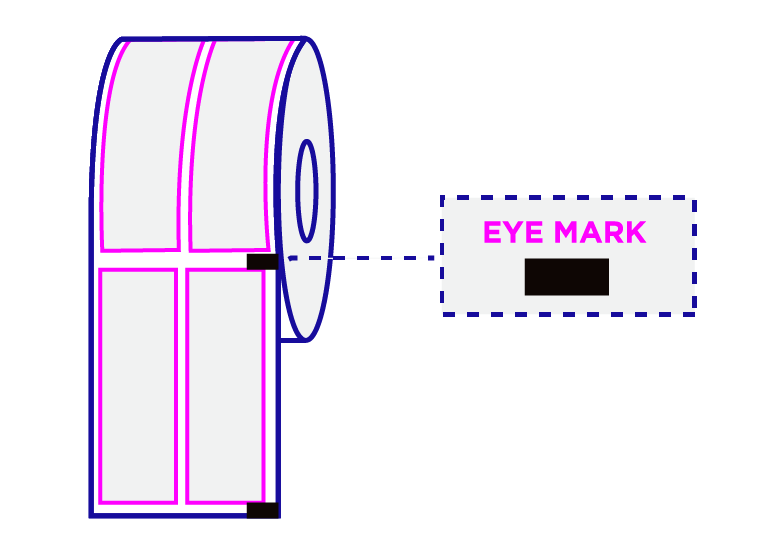

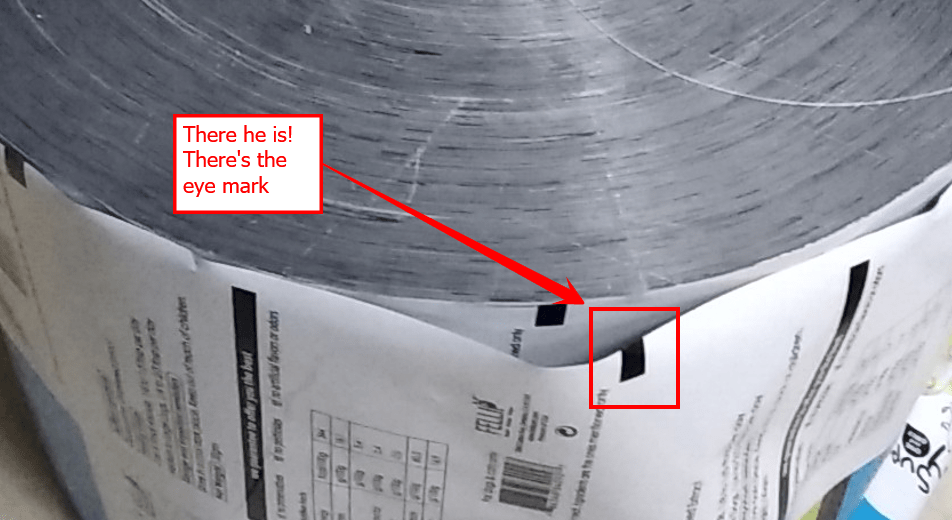

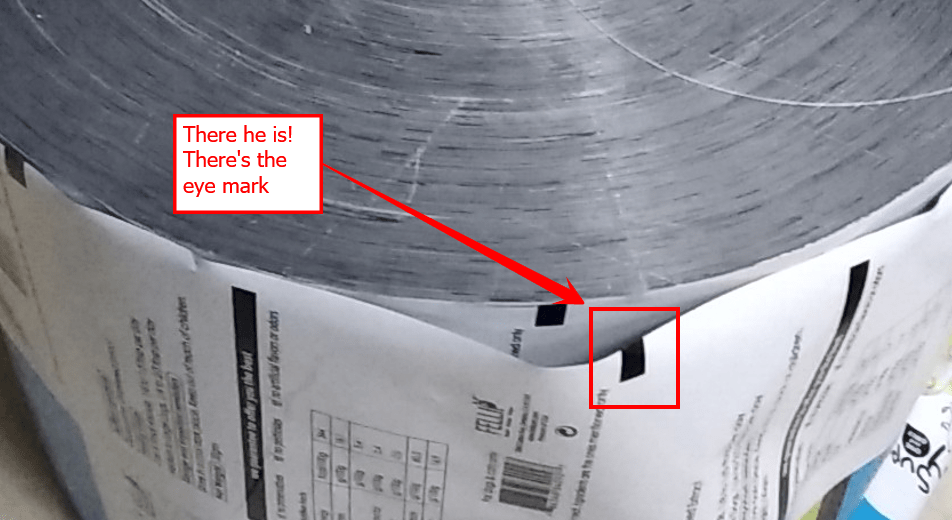

Roll Fed Form fill machines, and other packing machinery need to be able to identify the point when the first label, or pouch starts and ends. If the machine cannot understand these locations, they will not process the package correctly. Therefore, there is strong need for a certain marking to guide the label machine to identify the label's start and end for a smooth process.

That is how the black box i.e., the eye mark for the machines to read using a optical reader.

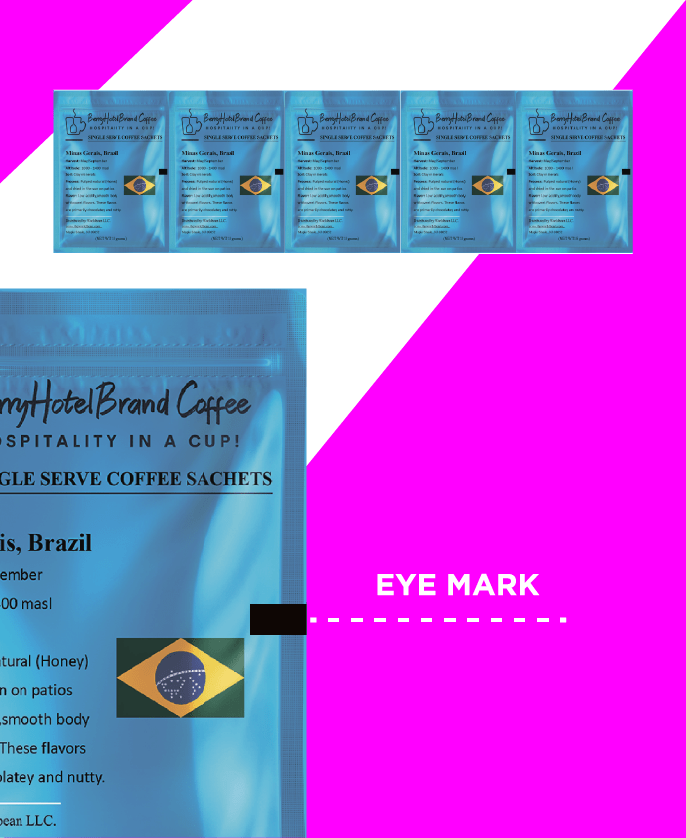

An eye mark is an important part of the pack as it helps tell the machine where it should cut the film on the packaging line. Then, since all the packs come on a continual loop, the reel is put into the packaging machine, allowing separate individual packs, folding them, closing the join, then sealing one end, filling it with the product, and finally sealing the other end.

Because the machinery can be meant to cut upon an offset from the eye mark, the eye mark does not need to be highlighted at the spot where the cut occurs.

An important thing to understand is that this mark does not affect the crimps or seals; it is only used for cutting.

Why is eye mark artwork still used on packaging?

The eye spot on the packet is a part of the custom design. The cutter guide and print specification provide the eye spot's position, size, color, and other important information. Beyond various advancements in the packaging. The companies are still using eye marks.

To answer this question, why are they still being used? Let us now look at the reasons behind this practice to have a clear idea about its importance.

It ensures that the giant roll of printed packaging is properly divided into smaller rolls within variance.

In addition, it also instructs the bag-forming machine where to make cuts during the bag-forming process. Without an eye mark, the sensor on the machine will not identify the mark and cut the film by the cutter causing uneven packs and unusable batches for the customers.

Finally, if a quality issue occurs, such as a printing problem on the packaging, it is useful to troubleshoot by determining which lane or pitches the defect occurred on. The printer can use this to look up information about their production records.

Although, these are some of the obvious reasons. However, in some cases, if the eye mark is missing in the design, then the company will have to face certain issues during the registration of the label of the product.

Why don't all pouches have eye marks on them?

Well here is a little secret, almost all pouches DID have a eye mark, but it was trimmed off before the final pouch was made. This is done to make the pouch more esthetically pleasing, and because the eye mark was only needed during the conversion of the pouch.

Have a question? We have the answer

The aim of this article is to shed light on the importance of eye marks so that it is easy for anyone to understand why they may need to be present on your packaging. If you have any further questions, please connect with us.

Tags