No products in the cart.

Trends and Opportunities In the

Candy Packaging Market

Like any other retail business, the candy market is increasingly becoming competitive and advanced in line with consumers’ tastes and preferences. However, one that’s setting brands apart is the designs and qualities of their packaging.

From high infographics, bright colors, impressive designs to imageries, packaging is continuously proving to be a game-changer in the candy market. Here are some trends and opportunities that’ll give you insights into moving with the candy packaging market and, most importantly, stand out on the busy shelves to get the sale done!

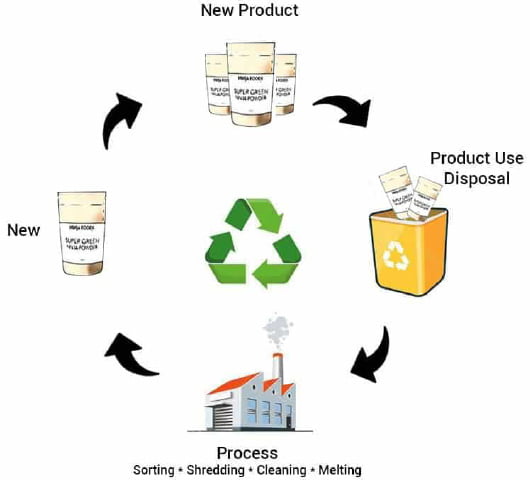

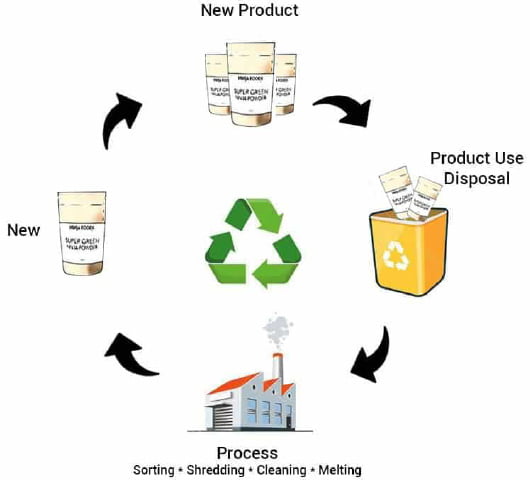

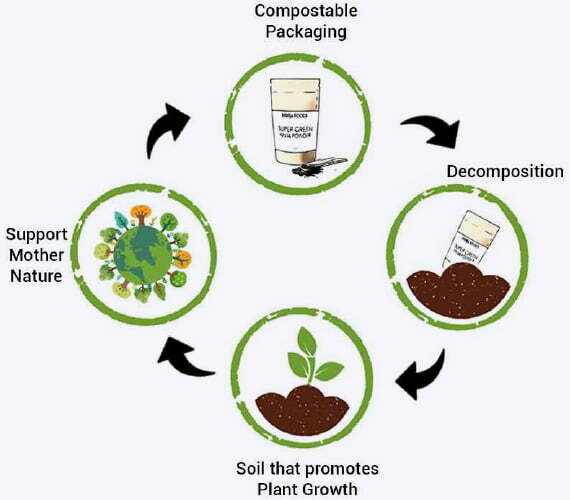

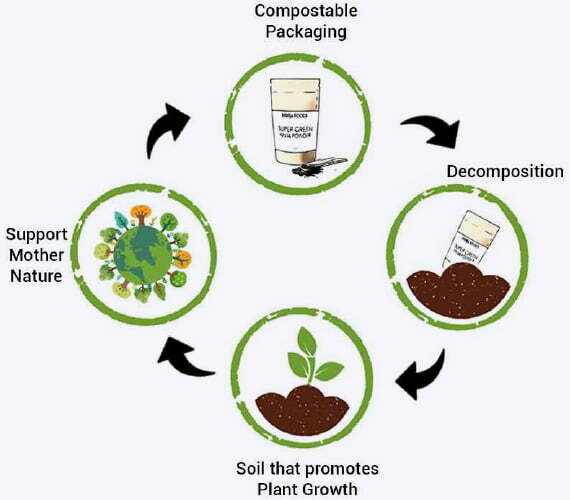

1. Sustainable and Compostable Materials

Eco-friendly or sustainable packaging is increasingly becoming a requirement by the authorities and a consumers’ preference. That explains why sustainable and compostable materials are being embraced in packaging candy and food products in general. For sure, this trend will continue to grow over time as more and more people continue to liken the ‘going green initiative’ in the wake of environmental conservation. And when it comes to compostable and eco-friendly packaging, Carepac is leading the way.

So, How Do We Excel in Compostable Packaging?

Carepac has the most recent FCN approved compostable packaging solutions that seamlessly compost under ambient conditions and are also made of renewable materials. We are always partnering with filmmakers and laminators to offer brands the newest and latest innovations in compostable barriers made of biodegradable plastics such as sugarcane corn and cassava.

Moreover, our bags are fused with enhanced barriers and multiple thickness options to preserve your candy for longer periods. Furthermore, we make sure that the most common pouch configurations such as 3 side seal, tamper-evident, stand up pouches, tubing, and square bottom pouch are strongly compatible with compostable materials.

Check out some of the compostable packaging materials we provide:

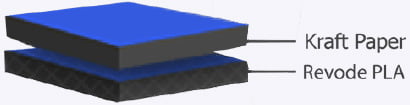

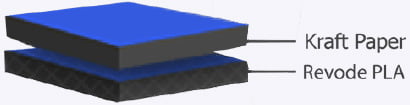

CareCompost KP Qualities

CareCompost KP is a kraft paper and PLA based compostable material that offers a great cost point.

- Exceptional price points and order sizes

- Multiple thickness layers

- Compatible with most pouch configurations with printable options

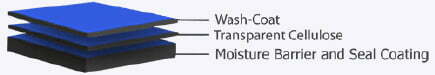

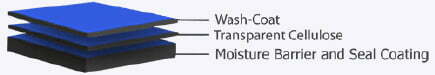

CareCompost NPT Qualities

This compostable material can be used to make pouches or bags which are totally see through, just like normal plastics. Its pros include;

- Moisture barrier

- Heat sealable

- Transparent to the eyes

- Anaerobic digestible

- Resistant to oil and grease, and are also made from renewable resources

CareCompost NKMEPS

This is a top of the line compostable lamination structure. Consisting of a NatureFlex bioplastic exterior with a metalized ambient compostable lining. This material provides both a great barrier and a traditional pouch look, along with full plate printing ability. This Material readily decomposes and biodegrades into biomass, water, and CO2. Some pros include;

- Requires no specialized composting facilities

- Food Contact Approved (FCA/D)

- Higher barrier than most compostable materials.

- BioPBS is used as a sealant layer.

2. Fold Over Gussets

Another trend that is moving the candy market when it comes to packaging is the fold over gussets. This pouch configuration has been popular in the dried goods industry and is now making waves in candy packaging. Here are some of the features that are making candy brands consider it;

- They are easy to fill and retain some shape in the gusset.

- Easily adjustable thus, you can increase the volume of the bag without increasing the overall length and width of the package

- It is less wasteful and more cost-effective as compared to the traditional cardboard packaging

- Due to its flexibility, it enhances storage space both at the manufacturer’s facility and on the shelves

- Its strong and durable high-barrier films allow for a longer shelf life of the candy, and consequently, decreases product recalls

- Again, its strong materials enable ease of package transportation both to the retailers’ stores and once a buyer has made a purchase

3. Haptic Coatings (Soft Touch)

Another candy packaging opportunity you need to consider is the haptic coating packaging –soft touch and amiable packaging. It is appealing and attractive to customers, particularly in foodstuff packaging. Hence, it can be a marketing gem.

And as a matter of fact, California Polytechnic State University research revealed that customers preferred soft touch coating vs. traditional coating and were willing to pay a 5% price premium on cosmetics. Studies have also shown that consumers are more likely to purchase a product if it engages their sense of touch.

Yet again, soft touch packaging can make the consumer feel as though the product is of high-end quality. And still, due to its comfortable and luxurious feel, it is perfectly suitable for high-grade and premium candies.

4. Pull Tab Zippers Instead of Standard Zippers

And when it comes to packaging features, the traditional standard zippers are fading away in favor of pull tab zippers. This is as a result of the so many advantages they have when it comes to loading, including;

- The entire top of the bag opens for loading; hence the producer or fillers never have to interfere/mess up with the zipper

- These pull-tab zippers are built on one face of the bag (usually the front) hence allowing the top part of the bag to be completely clear and opened for loading

- They can be great for roll stock pouches mainly because they’re built on one face of the bag

- Less time and effort is required when opening the bag as compared to a bottom loading 3-seal, and again it ensures that the bag is full sealed at the end of loading

- It is most suitable for high-speed filling environments like in auto/machine filling processes

Furthermore, pull-tab zippers allow customers to easily scoop out, tip or snack from right in the package, thus user-friendly.

Wrap Up

The next time you’re in the market for candy packaging, consider these trends and opportunities, and you’ll surely be ahead of the competition. And even if not ahead, then you’ll be keeping pace with the market and consequently your competitors.

So, if you need any of these trends and opportunities, such as compostable/eco-friendly candy packaging, look no further than here. Carepac can help you choose the best candy packaging that’ll make you stand out on the competitive shelves. You can reach out to usfor a free consultation if you need to learn more.

Tags