No products in the cart.

Retort Packaging

What is Retort Packaging? Everything You Need to Know About Retort Packaging

The US army promoted the idea of retort pouch packaging in 1950, and research continued until 1960. It was first introduced in Italy by the United States Army Natick R&D Command in coordination with Reynolds Metals Company, and Continental Flexible Packaging. In 1978, these companies were awarded the Food Technology Industrial Achievement Award for their invention. “A retort pouch is a laminated plastic packaging that is thin, lightweight, and flexible and is used to hold processed meals. It's a aluminum can and glass jar alternative that combines the lifetime of traditional food preservation techniques with the convenience and benefits of a thin, pliable container”.

Packaging processed food in cans has several advantages. It doesn't need to be refrigerated and has a very long and consistent shelf life. The issue was not with the seal or preservation procedure, but rather with the cost and inconvenience of cans and jars. Cans and glass jars are expensive in terms of both materials and transportation.

In comparison retort pouches are compact and lightweight, making them ideal for packing many products, including many foods. As a result, they provide significant cost reductions in transportation and shipment. These pouches require less storage space before filling because they lay flat while empty, lowering warehousing expenses. Plus, they can be clear so customers can see what's inside.

Wide-Scale Adoption

Additionally with the wide scale adoption of flexible packaging by many industries, consumers are accustomed to seeing many food items presented in pouches. Read on to learn more information.

When it comes to sterilizing operations, the lightweight packaging also saves money and improves productivity. Filling the pouch and then subjecting the sealed package to ultra-high heat is the retort sterilization method. The thin packaging transmits heat quickly, allowing sterilization to take place up to 40% faster than with jars and cans. Faster sterilization consumes less energy and, as a result, is less expensive. It also enhances the overall taste of your foods and raises your company's production capability. Our product checks all the boxes!

Easy-Open Features

Retort pouches are available with a number of features, allowing you to select packaging options that complement your products while also directly meeting the needs of your customers.

Choose from a variety of retort pouch materials, pouch configuration, including lay-flat and stand up pouches, and combining features such as easy-open, resealable, and spouts allows the retort pouch to be customized to the individual needs of your use.

Retort pouches also provide additional space for front-facing marketing materials because of their enhanced surface area. Consumers and retailers alike benefit from the use of retort packaging.

Easy to use: Easy-open features like tear notches make retort pouches user-friendly, removing the need for can openers or adequate hand power to open jars. They also take up minimal space after they've been used. Gusset packaging allows pouches to stand upright, making it easier for shops to display products. It reduces shelf space while also creating a visually appealing product presentation. On top of that, it can extend your product shelf life.

It's What's on the Inside

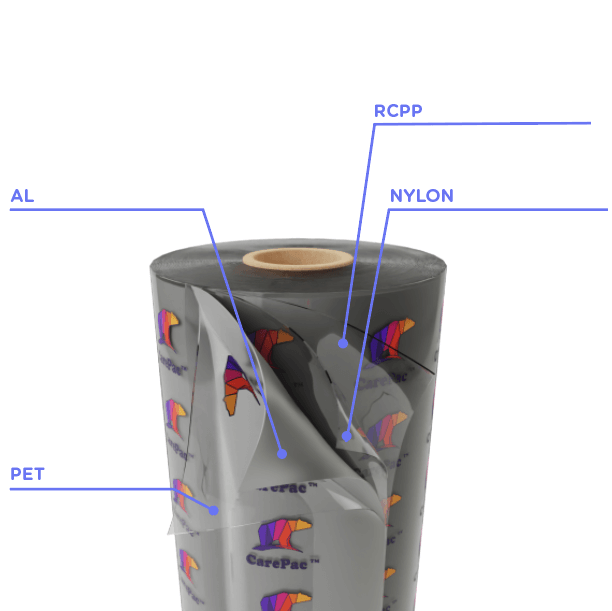

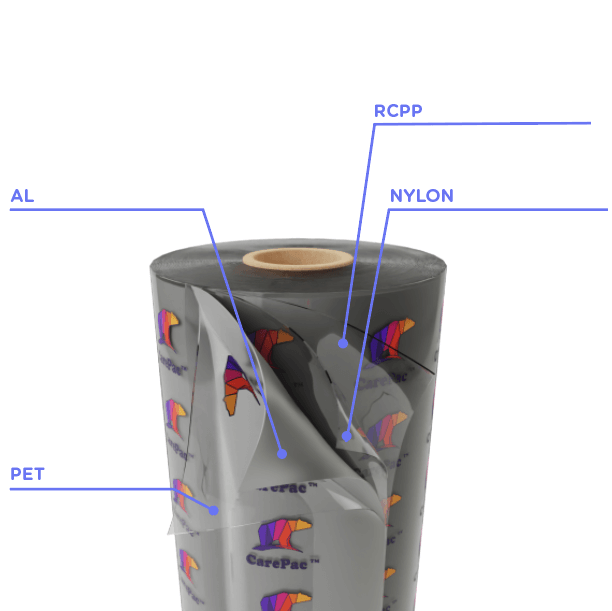

The key to an effective flexible retort pouch lies in the film lamination structure, the composition of which is integral to success both to ensure the retort sterilization process is successful and to preserve the shelf life of the products. Each custom CarePac retort pouch is made up of four layers, as shown in the image.

The materials used in the packaging of retort pouches are FDA approved, and can be sterilized at high temperatures above 210F.

Retort Pouch Applications / Uses

In terms of revenue, the retort packaging market is projected to expand at a CAGR of 5% by 2027, due to consumer demand for convenience and better flavor retention . Pouches currently account for 53% of the retort packaging market, with 4.3 million tones expected to be produced in 2027. Market participants are developing packaging films that can be recycled and endure ambient medium- and high-barrier retort applications because of the large incremental and volume opportunity in the retort pouches environment.

Reduced Use of Preservatives

Microwave- Compatible Retort Pouches

By removing preservatives, packaged food products must be sterilized for longer shelf life. All germs are eliminated by wrapping food in a special carrier film (the retort film) that can endure temperatures of roughly 130 degrees Celsius. When sterilized, retort packaged foods have had all bacteria effectively destroyed. Products in retort packaging have a shelf life of approximately 18 months, according to the TMR research. The advantages of retort packaging over traditional packaging encourage its commercial adoption. With antimicrobial food packaging, germs won't be on the menu!

While traditional retort film structures incorporate nylon, the advent of high barrier plastic films using EVOH, or PVDC coatings, allow for microwave-compatible flexible containers that do not require refrigeration allow items to tolerate processing and storage conditions while retaining their flavor and texture. Retort packaging is believed to be both cost-efficient and excellent in protecting products from air and moisture.

Depending on the intended use application, retort pouches are widely used in the food and beverage industry as they represent a durable, lightweight, and cost-effective alternative to metal and glass cans for the packaging of processed food products. The food and beverage industry is followed by the healthcare sector.

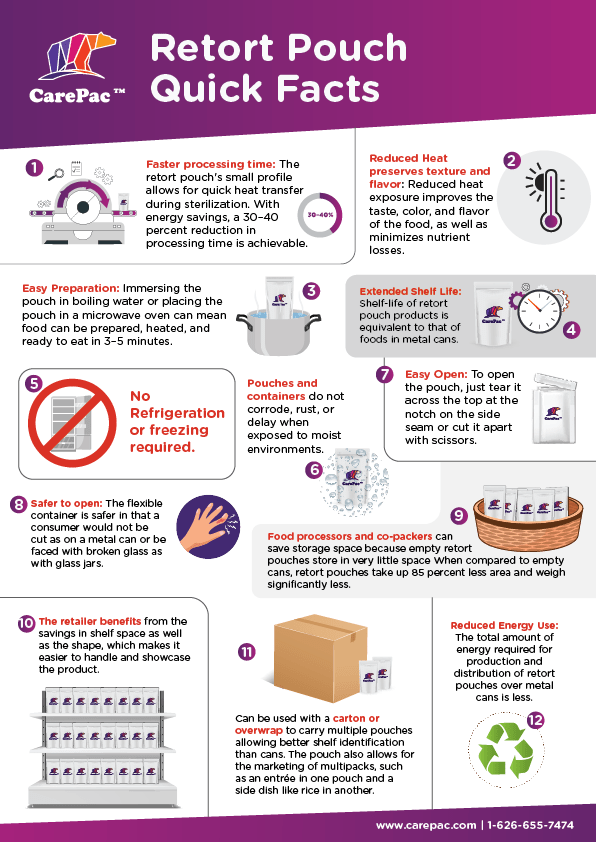

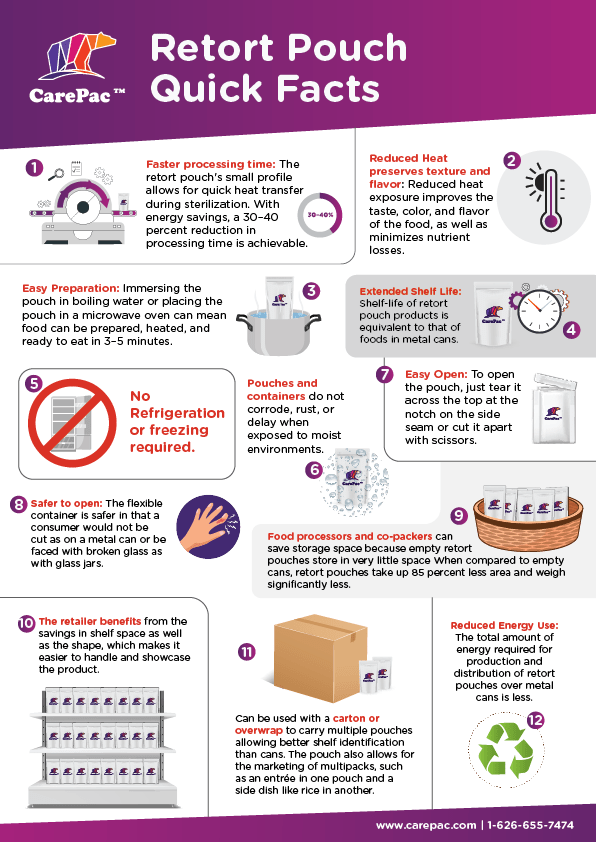

Retort Pouch Quick Facts

The pouch's or container's small profile allows for quick heat transfer for both preparation and sterilizing during processing. With energy savings, a 30–40 percent reduction in processing time is achievable.

Reduced heat exposure improves the taste, color, and flavor of the food, as well as minimizes nutrient losses.

Immersing the pouch in boiling water or placing the pouch in a microwave oven can mean food can be prepared, heated, and ready to eat in 3–5 minutes.

Storage space required of the retort pouch or container in a paperboard carton is no greater than that for cans; disposal space is less.

The pouch also allows for the marketing of multipacks, such as an entrée in one pouch and a side dish like rice in another.

Shelf-life of retort pouch products is equivalent to that of foods in metal cans.

Refrigeration or freezing is not required by packers, retailers, or consumers.

Externally, pouches and containers do not corrode, and product–container interaction is minimal due to the non-reactive pouch liner.

To open the pouch, just tear it across the top at the notch on the side seam, or cut it apart with scissors.

The flexible container is safer in that a consumer would not be cut as on a metal can or be faced with broken glass as with glass jars.

Food processors and co-packers can save storage space because empty retort pouches store in very little space When compared to empty cans, retort pouches take up 85 percent less area and weigh significantly less.

The retailer benefits from the savings in shelf space as well as the shape, which makes it easier to handle and showcase the product.

The total amount of energy required for production and distribution of retort pouches over metal cans is less.

Why do certain industries prefer retort packaging?

Historically, the primary goals of retort packaging for shelf-stable food products have been to extend the time a food product may be stored in a shelf stable state, without refrigeration or other externally applied preservation methods, and to maintain sterility during the distribution process from manufacturing to end-user consumption. However, the uses for retort pouches have become more varied in recent years, and it continues to evolve. Manufacturers are continuously looking for new categories and products to offer to consumers who demand fresher-feeling, hassle-free options. In today's highly competitive food sector.

Food and pet food manufacturers are contemplating innovative approaches to custom food packaging in their supply chain to make it more appealing to consumers, as packaging creates a valuable link between manufacturers and consumers. The durability of retort packaging is excellent that help to increase the shelf life of food which is approved by the FDA and various regulatory agencies. Growing consumption of ready-to-eat and packaged food among consumers and rising demand for lightweight and compact packaging materials is the major factor driving the growth of the Retort Packaging Market.

How is Retort beneficial to the food industry?

Popular Uses of retort Packaging

In bags made of this type of food packaging materials, you can put almost any type of processed food. They are also frequently used by pet food manufacturers to package wet food and treats. Juice and yogurt drinks benefit from options that can be punctured with a straw. They're good options for ready-to-serve entrees like curries, pasta with sauce, and other pre-cooked dinner items. These containers are also used by manufacturers for soup, rice, and pre-cooked vegetables.

Tags