No products in the cart.

Packaging Life Cycle Analysis: Why It Matters

What Is Packaging Life Cycle Analysis (LCA)?

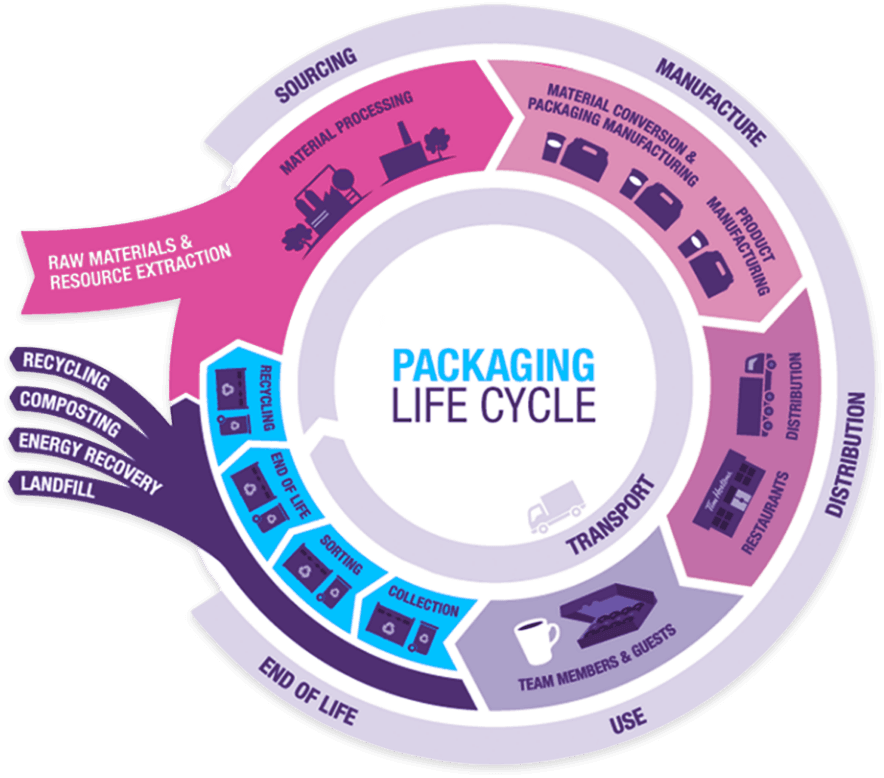

A life cycle assessment (or analysis) is defined as the methodology used to assess the environmental impact of a product throughout its life cycle. It's used in the packaging industry, specifically, to determine the product life cycle and environmental impact of different types of packaging, from cartons and flexible packaging materials to plastics and aluminum cans. A packaging life cycle assessment is crucial to reducing your environmental footprint, as it can have a positive impact on ocean plastic pollution, methane emissions, greenhouse gas, energy and water usage, and other key environmental impact categories that affect sustainability.

The key stages of a packaging life cycle assessment include looking at raw material extraction, manufacturing, transportation, use, and the packaging's end-of-life (disposal, recycling, composting.) Several tools used for life cycle assessments of packaging materials include specialized software like SimaPro, GaBi, and PIQET, and screening tools like EcoImpact-COMPASS. These tools and software don't just make assumptions -- they assess the entire life cycle of a packaging solution so companies can make informed decisions about the materials and manufacturing process of their existing (and future) packaging solutions.

Why Packaging LCA Matters in Design

The life cycle assessment of your packaging has a huge impact on packaging design. Businesses use the results of their life cycle assessment (LCA) to choose smarter, more sustainable materials and plastics. This helps them reach their sustainability commitments and reduce their carbon footprint. Since the LCA is a comprehensive review that looks at things like raw material extraction, end of life, and multiple aspects of the supply chain, it also helps prevent greenwashing (the practice of appearing to be eco-friendly on the surface but not actually having any impact or making progress on environmental goals.)

In addition to helping evaluate material selection, packaging research also informs design decisions related to functionality, weight, disposal, and recyclability. For example, a company may discover through an LCA analysis that reducing packaging weight or eliminating unnecessary layers can significantly lower emissions during transport and manufacturing. It can also highlight opportunities to progress towards a shift toward mono-material designs that are easier to recycle.

By incorporating LCA assumptions and insights early in the design process, businesses can focus on creating packaging that balances performance, consumer appeal, and environmental responsibility—leading to more transparent, data-driven decisions across the product life cycle.

Comparing Packaging Materials Through an LCA Lens

If you're wondering what the results of a life cycle assessment might look like in real life and how companies evaluate the info to make packaging decisions that can impact climate change, here's an example. Say you're comparing the environmental performance and impact of a glass bottle vs. a flexible pouch -- here are some of the takeaways you might expect from your LCA results:

Flexible pouches waste less energy and use fewer materials, making it more resource efficient. On the other hand, glass is heavier than most plastics and uses more energy, but is made from abundant natural materials and is often easier to recycle.

When it comes to transportation, pouches can reduce the carbon footprint during transport while glass's weight and fragility can increase its environmental impact.

Glass has a circular life if properly collected and recycled, while pouches have limited recycled content and even less recycling infrastructure.

As you can see, no packaging alternatives are better than something else. The best choice depends on context, including manufacturing, transportation, water usage during the production life cycle, and end of life plans for the product. You'll need to evaluate the data and choose the materials and services that make the most sense for you and the overall environmental impact of your company.

How CarePac Helps You Make Sustainable Packaging Choices

At CarePac, we provide ourselves on providing a variety of material options to our customers, and we're constantly working on the sustainable development of new product offerings. If you'd like to review the life cycle assessment (LCA) of any of our products or materials, we'd be happy to provide them and answer any questions you have about our sustainable products. Currently, we offer packaging materials that include PCR plastic, recyclable packaging, PFAS-free food packaging, and several biodegradable and compostable options. We're all about reducing our carbon footprint and can help you do the same.

By working with us, you can also reduce your environmental impact in other ways. For example, you can avoid unnecessary overpackaging or poor end-of-life options. Whether you're concerned about the raw material used in your packaging or the energy and tools required during the manufacturing process, we can help you make informed packaging decisions that'll have a positive environmental impact. We're all about transparency with our packaging design and services.

Final Thoughts: Think Beyond the Circular Economy Buzzwords

When it comes to packaging design and life cycle assessment, it's important to emphasize data-driven decision making over "eco-friendly" marketing claims that have zero substance. If you truly care about improvement in sustainability, we can help you evaluate your existing packaging framework and system boundaries and identify areas where you can enhance sustainability and minimize your environmental impact.

Today’s consumers and stakeholders are looking for authenticity and measurable impact when it comes to sustainability—not just green-colored packaging or buzzwords. CarePac is your trusted partner in navigating the innovation and complexities of sustainable packaging. With our expertise in materials, compliance, and life cycle assessment (LCA), we can help you align your packaging choices with real sustainability metrics and data, ensuring that your environmental efforts are both credible and effective—not just cosmetic.

Packaging LCA FAQs

Here are some common questions we receive about sustainability and how the proper packaging choices can help reduce your environmental impact.

A life cycle assessment (LCA) measures the environmental impact of a product through every phase of its life – from production to waste (or recycling, etc.). But LCA isn't simple – there are countless factors involved and it can be difficult for manufacturers to review the results and make a decision right away.

The core challenges of sustainable packaging often come down to cost, infrastructure, durability, and regulatory complexities. For example, sustainable packaging is often more expensive due to lower availability and less-established supply chains, but its environmental impact cannot be understated.

To assess the environmental impact and sustainability of your packaging, you can use life cycle assessments (LCAs) and focus on key data like carbon footprint, resource use, and recyclability. By reviewing the results, you can find areas of improvement when it comes to resource use, waste, energy use, and other sustainability factors.

Since a life cycle analysis evaluates at so many different factors and can use several different tools, the methodology can take anywhere from 3-6 months to complete.

Let's Get Started

Made In

The USA

Full Pouch

Customization