No products in the cart.

Packaging Seal Integrity Testing: Why It Matters and How It’s Done

What is Seal Integrity Testing?

Seal integrity testing is exactly what it sounds like: it's the process used to identify quality control issues regarding the seal strength of a package. Packaging seal integrity testing ensures a bag can withstand external pressures and avoid small leaks or issues with internal pressurization. It goes beyond a simple visual inspection and uses a standard test method (or a combination of methods) to verify the package integrity, specifically the integrity of the seal.

Many people use the terms "seal strength" and "seal integrity" interchangeably, but they actually refer to two different things. Seal strength refers to the ability of the seal to withstand a specific pressure or load, and seal integrity refers to the ability of the seal to maintain a proper seal and prevent gross leaks. This blog will discuss packaging seal integrity specifically, and why packaging integrity testing can help extend the shelf life of your product.

Why is Seal Integrity Testing Important?

Seal integrity testing is important for several reasons. This type of flexible package testing can aid with leak detection, ultimately ensuring your product stays safe during manufacturing, transport, and storage. It can also ensure you comply with industry standards and regulations.

Ensuring Product Safety and Quality

A compromised seal, regardless of the package shapes, can cause your product to be exposed to various environmental conditions, like moisture and oxygen. This can lead to contamination, which can impact food safety or, if it's medical packaging, can lead to sickness or death.

Meeting Industry Standards and Regulations

There are several regulatory standards that must be met, particularly in the food and pharmaceutical industries. If you go through package testing and are confident that your seal will stay intact through the life cycle of your product you'll be in a better position to meet these regulations.

Extending Shelf Life and Saving Costs

Testing for seal integrity reduces product waste by identifying weak or faulty seals early in the process -- before they become a major problem for you or your customers. This can lead to cost savings and an improved bottom line, since your quality control process will be enhanced with this type of testing.

Common Methods for Seal Integrity Testing

There are several popular methods for seal integrity testing, including bubble leak testing and dye penetration testing. We'll discuss some of the more popular product quality testing methods below.

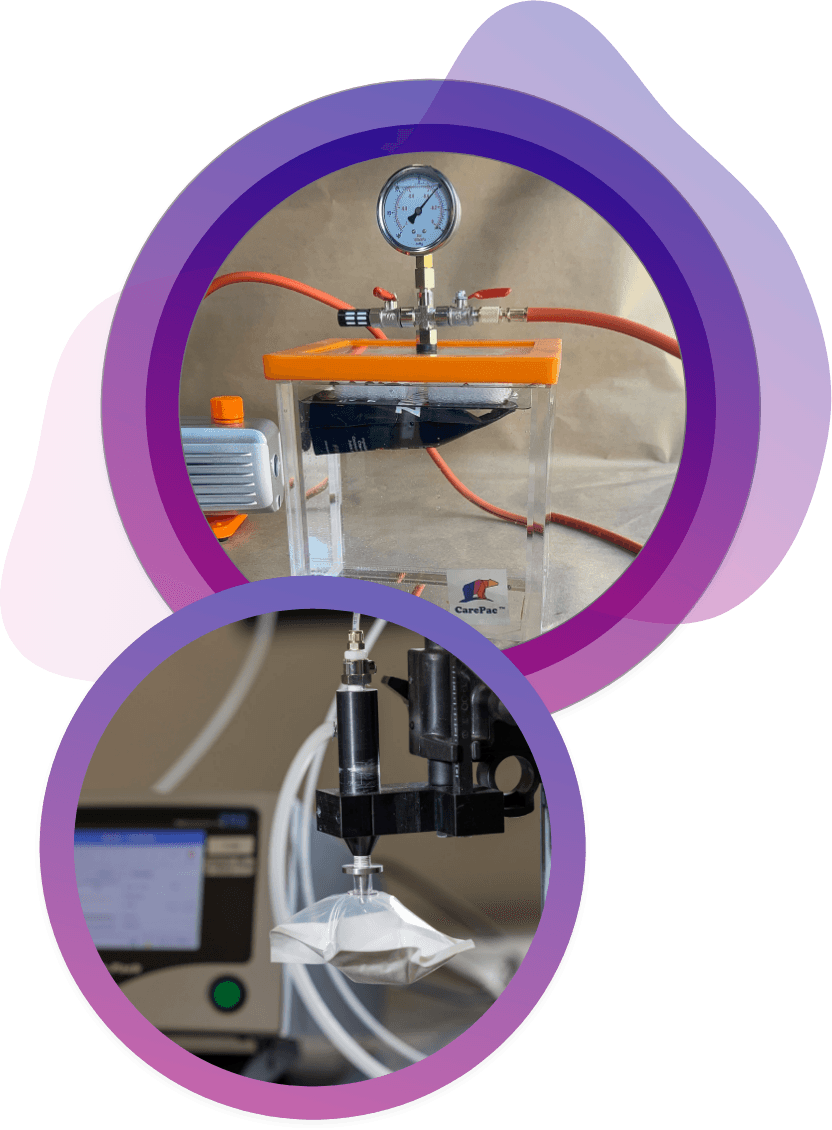

Vacuum Decay Testing

Vacuum decay testing detects leaks in sealed packaging by placing the package inside a chamber, evacuating the air to create a vacuum, and then monitoring the pressure inside the chamber over time. If the pressure rises significantly, this is an indication of a leak.

Burst Testing and Peel Testing

This type of leak testing measures the force required to burst or peel a part a sample strip cut from the seal material. This is a popular method of detecting gross leaks in medical or pharmaceutical packaging.

Bubble Emission Testing

Bubble leak testing involves submerging the flexible package into a water or solution. The package is then inspected for bubbles. Any issues with the package seal can be identified as a steady stream of bubbles being released by the entire package during testing.

One of the most widely used methods for this test is ASTM D3078, the Standard Test Method for determination of leaks in flexible packaging by bubble emission. This method is particularly effective for detecting gross leaks in sealed packaging. The package is submerged in water, and a vacuum is applied to detect leaks by observing air bubbles escaping. It is commonly used in food, pharmaceutical, and medical device industries to ensure package integrity. For more information on vacuum-based leak detection, visit Haug Quality's Pack-Vac Leak Detectors.

Watch our video on Bubble Emission Testing

Best Practices for Seal Integrity Testing

When it comes to inspecting your packaging materials for leaks or tears, there are several best practices to keep in mind:

Make sure to establish a process, and that your entire team is trained on the appropriate testing measures for whatever you're manufacturing

How CarePac Supports Seal Integrity for Flexible Barrier Packaging

CarePac is a leader in the flexible packaging industry and is proud to provide packaging solutions that are strong, compliant, and of the highest quality. Our packaging expertise focuses on delivering products that meet the strict requirements of various industries, including the food, pharmaceutical, and medical device industries.

Our flexible barrier packaging is designed for optimal protection, ensuring that your products remain safe and secure throughout their lifecycle. We place a strong emphasis on regulatory compliance, and our packaging adheres to global standards outlined by the FDA and other relevant regulatory bodies. One of the standout features of our products is our focus on strong, reliable seal integrity. We use state-of-the-art materials and manufacturing techniques that will help extend the shelf life of your products.

If you're ready to start your project or have questions about our manufacturing process, contact us today to get started.

Let's Get Started

Made In

The USA

Full Pouch

Customization