Subtotal: $0.00

FREE SHIPPING ON ALL ORDERS

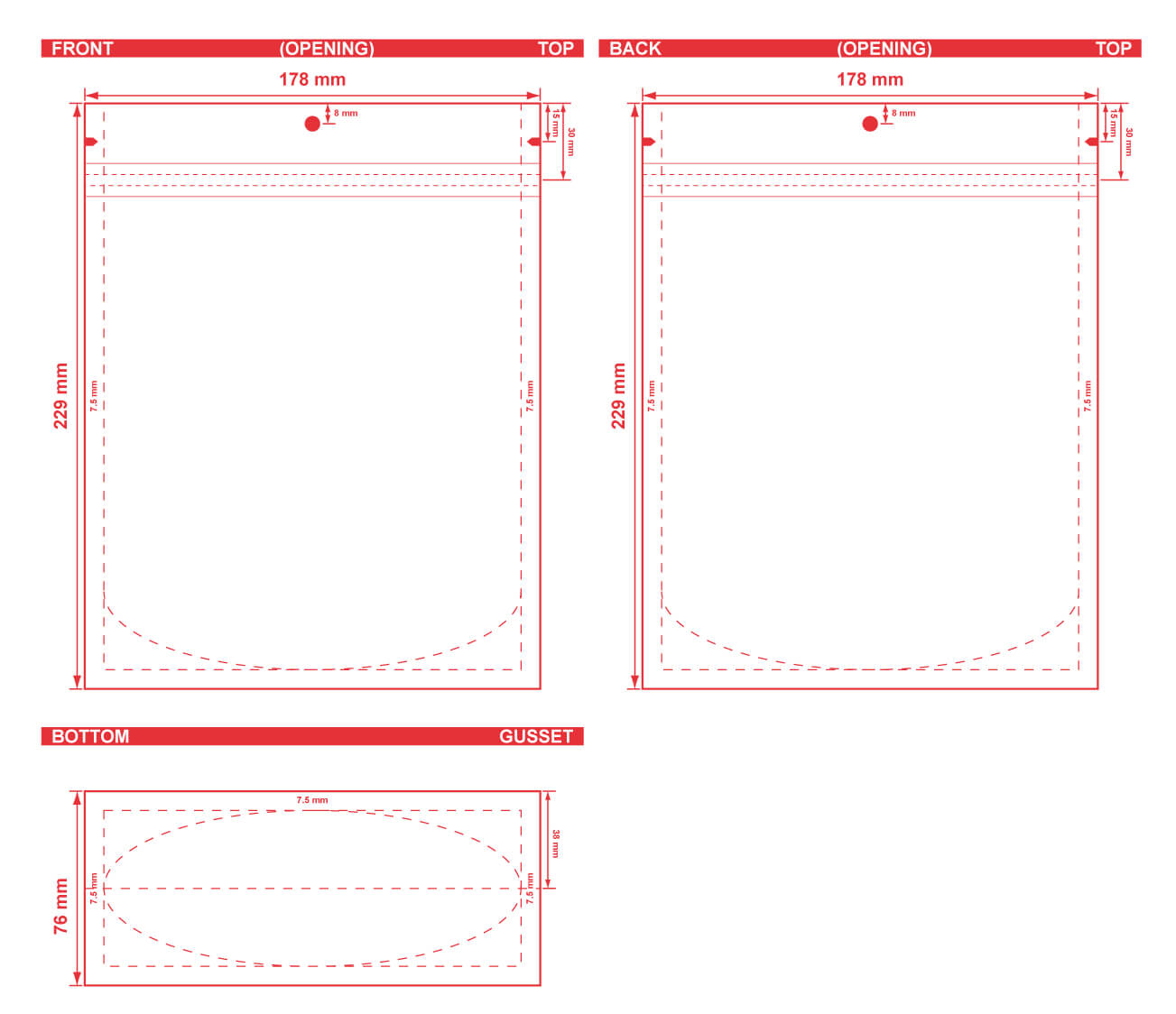

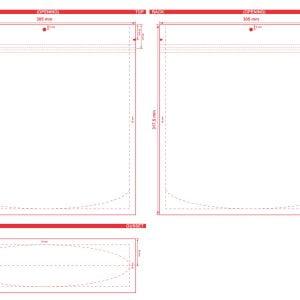

Custom Stand-Up Pouch 7x9x3 Dieline

$0.00

File Setup Suggestions

Minimum Sizes

- Type: 4 point bold, 6 point bold if reversed / knocked out (white)

- Line Weight:

- Vertical: .46 Point. 1.00 point if reversed/knocked out (white).

- Horizontal: .6 Point. 1.25 point if reversed/knocked out (white).

- Line Screen:

- V1: 120-133 line screen based on 300dpi imagery. 5% minimum dot.

- R2: 177 line screen based on 300dpi imagery.

- Under 15% Screen: Eliminate from CMYK mix or convert to 100% PMS Spot.

- Bar Codes: LINE ART (not .jpg, .gif, or .png) and be between 80% and 120% and NOT cropped or truncated.

Color Handling

- White Ink: Requires a color plate on non-white materials. 2 white plates may be required for clear material with product window. Please note white ink is not 100% Opaque.

- Process Black Ink: Please use ONLY for CMYK, half tones, and effects such as drop shadows.

- Line Black Ink: Required to be used for text, lines, sold coverage and barcodes.

- Spot Colors: Most likely Required for colored Type, Lines, and Large Solid Coverage. Often requires 2 plates per color, one for Solid Coverage, another for Tint / Screens. Must be designated with STANDARD Pan-tone Matching System (PMS).

Placement Guidelines

- Avoid placing critical graphics in the following areas:

- In zipper area

- Seal zones

- Around hang hole

- (Examples of critical graphics include: USDA icons, barcodes, regulatory compliance information)

-

- Bleeds: Generally, ¼” bleed Required at top and bottom of bag. Unless Trim cut or reverse over trims are employed, (speak with your sales associate).

- Plate Gaps: Flexographic products: 1/16 – 3/32” Un-printed plate gap will be on left and right edges of Flexo plate printed projects.

- Travel and Variation: Production features such as image placement and feature location have a tolerance and can TRAVEL. Overall dimensions and feature locations tolerances are +/- 1/8″. Image location tolerance on printed projects is +/- 1/16″. Film Thickness +/- 12.25um.

Crossover – For Full bleed Projects

- Type A = Left-to-Right seamless symmetric cross over. Standard Preferred Crossover

- Type B = Non-symmetrical crossover. Trim Cut Projects

File Format & Graphics Handling

- Please develop art in a layered file built in Adobe Illustrator.

- Vector line art for all text and graphics. (critical)

- Please do not create traps

- Please outline all type.

- Apply all affects.

- Remove all unused layers, please do not hide or /turned off layers on final art.

- Photographs / Images (if applicable) MUST be 300 dpi CMYK & Linked

- If including photographs / images that can be assigned a Pan-tone color: Use a placed background gray-scale or PMS Duo-tone.

- Assign Pan-tone colors if applicable.

- Keep vector elements in illustrator.

- Please do not use Photoshop for Typesetting or use Smart Objects that require Spot Color or Trapping.

Digital Printed Projects

- All digital printing is CMYK, PMS and spot colors will be approximate.

- All digital printed projects are Trim Cut

- All Digital printing is full bleed.

- Non-symmetrical crossover is ok, but may require changes to your design in pre-press.

- Speak with sales associate 1-949-541-7837, if you want to print gusset on a digital project.

- A flood white plate, or two, may be required on digital projects on clear material to build color.

Proofing

- PDF Proofs are used for layout and contents and are Not color accurate and will display differently on each monitor and will NOT be used for color matching.

- Only a current Pantone Color Fan should be used for spot ink color evaluations.

- FINAL COLOR can be affected by the material color and printing / lamination / varnishing process.

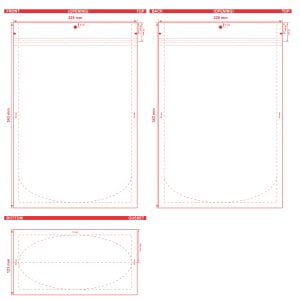

Clear Stand-Up Barrier Pouches 9x13 1/2x4 3/4 S-21654 Dieline

Clear Stand-Up Barrier Pouches 9x13 1/2x4 3/4 S-21654 Dieline