No products in the cart.

What Is HACCP and Why It Matters for Food Packaging Safety

What Is HACCP Food Safety?

The Hazard Analysis and Critical Control Points (HACCP) program is a risk-based food safety management system that's designed to identify, evaluate, and control hazards in the food production process, including packaging. The HACCP food safety plan forms the foundation of modern preventive controls for the food supply chain and aligns closely with the Food Safety Modernization Act (FSMA). The HACCP food safety plan is a requirement for many businesses in the food supply chain, including food manufacturers, schools, and the companies and personnel involved in the retail and food industries.

Why the HACCP Food Safety Program & Critical Control Points Are Important for Food Packaging

The HACCP food safety plan is important for food packaging because the packaging and packaging materials itself can introduce hazards and food safety risks, including chemical residues, physical contaminants, and improper sealing. By establishing quality assurance protocols, preventive measures, and identifying potential hazards before they become issues, the HACCP food safety plan can help food packaging companies prevent issues before they occur and establish corrective actions when they do. This is a vital component of CarePac's preventive quality control systems and VOC testing, ensuring our raw materials and packaging remains compliant with the HACCP, FSMA, and PCQI.

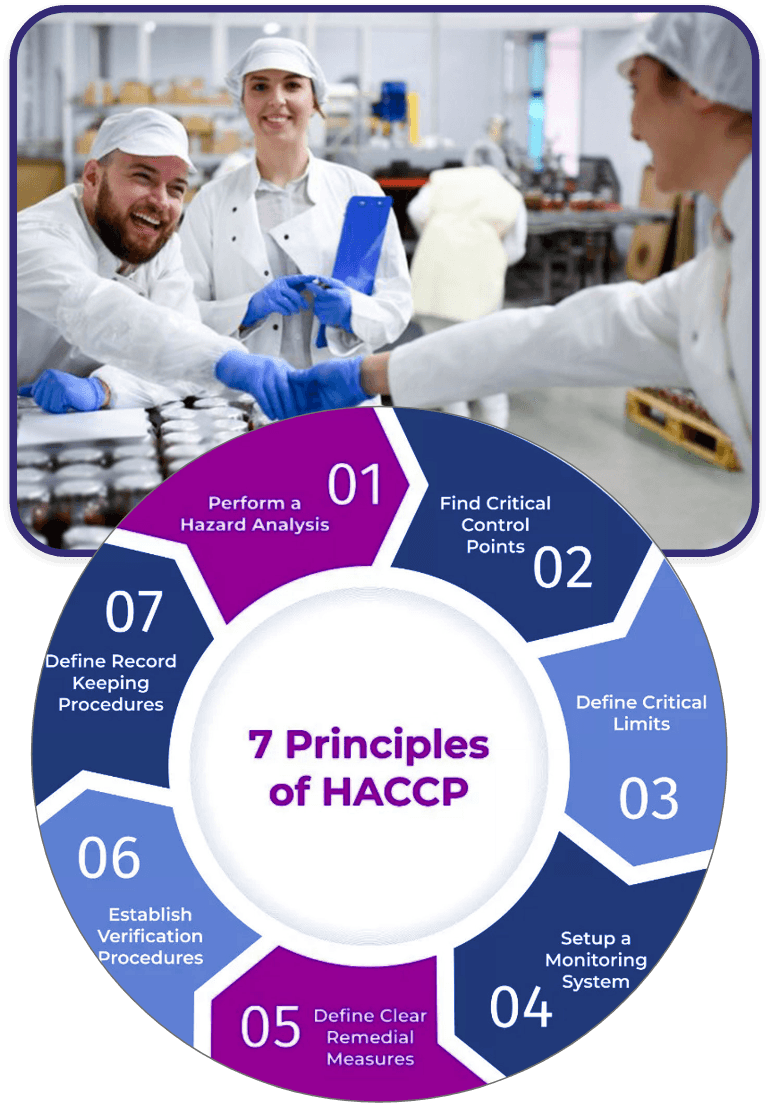

The 7 Principles of HACCP Implementation

When it comes to the HACCP food safety plan and becoming HACCP certified, there are seven principles that have been established that can help determine critical control points and support controlling food safety hazards. These are:

1. Conducing a hazard analysis (i.e., identifying hazards, including biological hazards)

2. Identifying critical control points (CCPs)

3. Establishing critical limits

4. Establishing monitoring procedures for manufacturing and processing equipment

5. Establishing corrective actions

6. Establish verification procedures

7. Establishing record keeping and documentation procedures

At CarePac, we take food safety hazards seriously and incorporate all of the above into our safety plan and quality management systems. We identify potentially hazardous products ahead of time all in an effort to safeguard public health. From our production equipment to the raw material we use, we adhere to all federal, state, and local regulations, including those outlined in the HACCP framework.

How an HACCP Plan Differs from FSMA and PCQI

You might be wondering how an effective HACCP plan is different from FSMA or PCQI. You can think of it this way: HACCP is the system that outlines good manufacturing practices and standard operating procedures, FSMA is the law, and PCQI is the person responsible for implementing and maintaining food safety systems. The FSMA's preventive controls and hazard identification methodology evolved from HACCP principles and and expanded them into more facilities, including food packaging and facilities that produce animal food. CarePac aligns with all three - we're a PCQI-certified team that manages HACCP-based safety systems under FSMA compliance.

HACCP in Action at CarePac

CarePac integrates HACCP methodology directly into our quality control process to ensure every packaging product is safe, compliant, and consistent. We evaluate each material and process step for potential contamination or quality risks that could lead to food safety risks, and the key production stages where the risk of contamination or failure are tightly managed. Additionally, we leverage VOC testing, in-line inspections, and per-batch sample checks to verify that CPPs remain within acceptable limits. All quality checks and test results are formally documented.

By applying the seven core principles of HACCP end-to-end, we can help minimize contamination risks within the food industry, verify structural integrity at critical control points, and ensure repeatable quality across every production run.

What HACCP Means for the Food Industry & CarePac Customers

Our HACCP-based quality system gives customers confidence that every pouch, film, and packaging component is produced with food safety and regulatory compliance at the forefront. By applying preventive controls throughout material selection, lamination, sealing, and final conversion, CarePac minimizes contamination risks long before they can impact your product, regardless of where your product falls on the food supply chain.

This approach not only strengthens safety, but also supports your internal QA programs. During audits or inspections, customers can rely on CarePac’s documented controls, VOC test data, and calibration records to demonstrate that packaging materials meet FSMA-aligned expectations and industry standards.

Transparency is built into the process: CarePac maintains lot-level traceability, detailed quality records, and material safety documentation — all available upon request. Whether you need VOC results, COAs, or manufacturing traceability, CarePac provides clear, verifiable data to support your food safety plan and reinforce confidence in your supply chain.

Partner With a HACCP-Based Packaging Company

CarePac’s HACCP-driven quality system, PCQI oversight, and FSMA-aligned preventive controls ensure your packaging materials are manufactured with safety and regulatory compliance built in. If you need VOC data, COAs, traceability records, or support for an upcoming audit, our QA team is ready to help.

Request documentation or connect with our quality specialists today to verify compliance and strengthen your food safety program.

FAQs About HACCP and Food Safety

Lets Get Started

Made In

The USA

Full Pouch

Customization