No products in the cart.

How Metal Detection Enhances Packaging Safety and Supply Chain Quality

Why Detecting Metal Is Critical in Packaging Quality Control

Metal detection is a crucial aspect of packaging quality control because even a trace amount of metal contaminants in the food production process can create costly recalls or safety risks for consumers. To help combat this risk to food safety, CarePac has proactively added a metal detector QC stage as part of its risk-based preventive controls. The inclusion of a metal detection system to identify metal contaminants in our production process benefits both manufacturers and consumers -- you'll be better protected from liability and your customers will be better protected from harm these metal contaminants may cause when it's present in packaged foods.

Whether you're packaging products for pharma applications, frozen products, packaged foods, or any other type of food product, our system will keep contaminants out of the food production pipeline.

How Metal Detection Systems Work

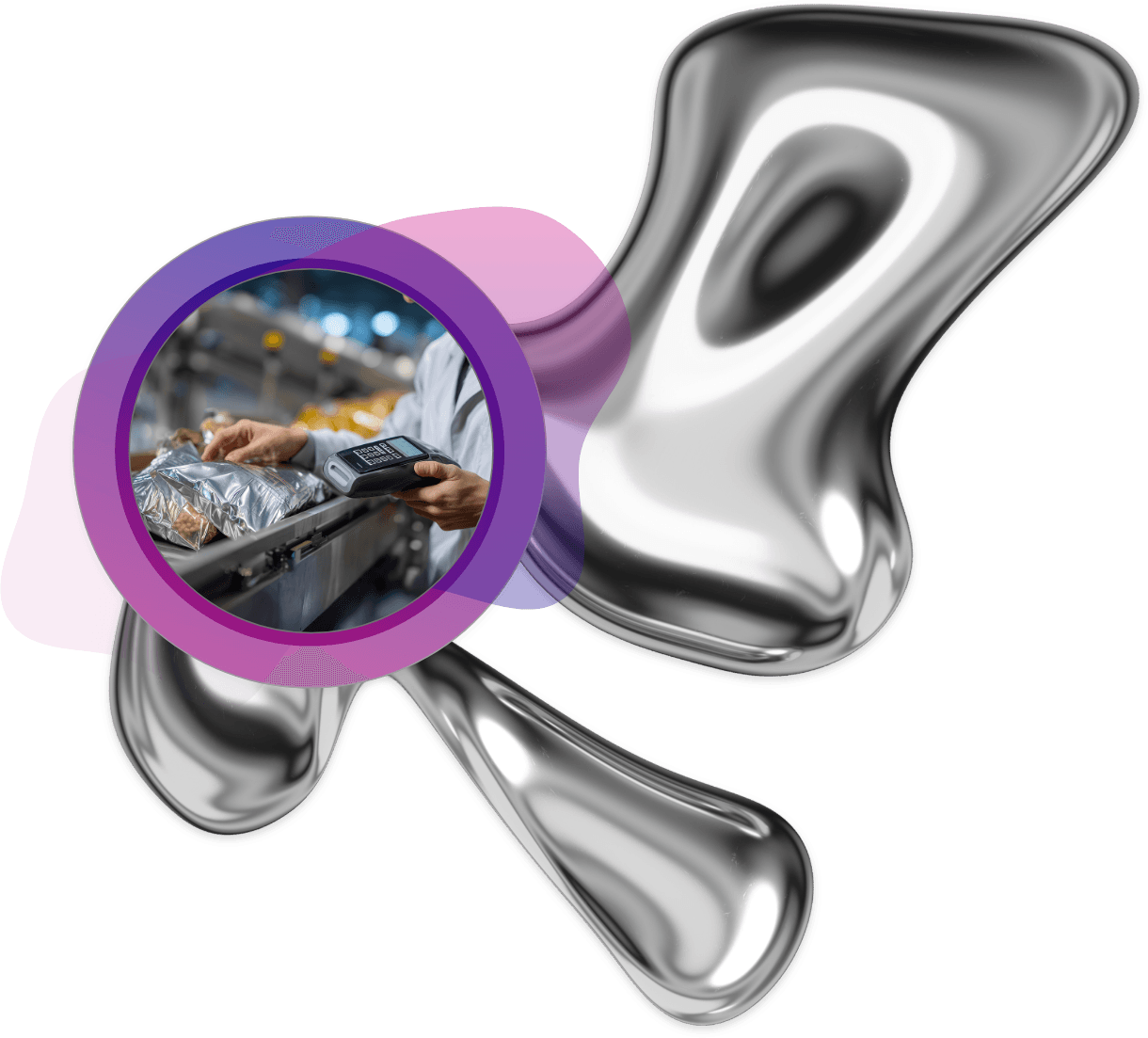

When it comes to our proprietary metal detection system, the metal detection process is straightforward: the finished bags pass through a sensitive metal detector that can identify metal contaminants, including ferrous, non-ferrous metals, and stainless steel contaminated products. Our metal detection thresholds are calibrated for precision and speed, which prevents bottlenecks in production. Our metal detection system is integrated in the final inspection stage, ensuring contamination-free packaging before shipment. With this system integrated into our production lines, you can rest assured that your packaging will be free from metal contaminants.

The Benefits of Detecting Metal Contaminants in the Supply Chain

Detecting metal contaminants early in the process protects the supply chain from product recalls, rejections, or shipping delays. Detection for metal contamination also protects food processors, co-packers, and retailers who rely on safe, compliant packaging. Reliable detection of metal contaminants early in the production process can also protect your brand from regulatory issues, especially those under the FSMA and HACCP frameworks. Finally, there are downstream benefits to consider, including less waste, better traceability, and stronger consumer safety and trust.

Integrating Industrial Metal Detection Into CarePac’s QC Process

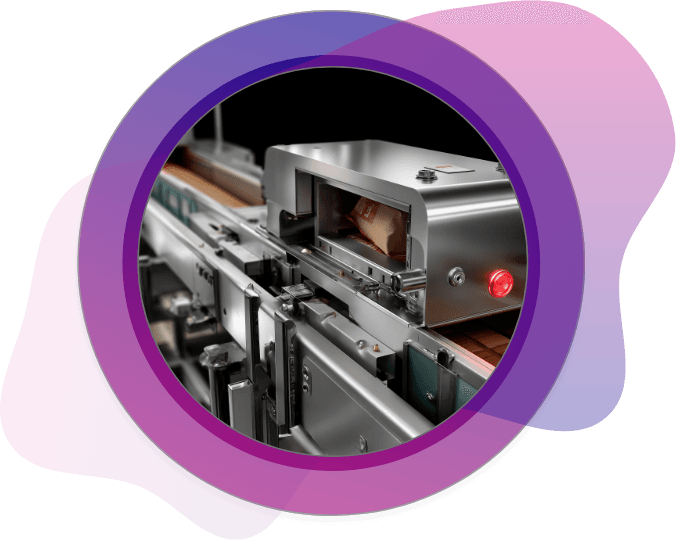

CarePac’s quality control workflow is designed to ensure every food-contact packaging product meets strict safety, regulatory, and performance standards. The process begins with material selection and incoming inspection, where all raw materials are verified for compliance, quality, and suitability for food applications. From there, printing and lamination quality checks confirm that graphics, adhesion, barrier layers, and structural integrity meet customer specifications and manufacturing requirements. CarePac also conducts VOC testing for emissions, validating that materials used in production remain within safe limits for food-contact environments.

As products near completion of the production process, metal detection during final QC serves as a critical safeguard, ensuring that each batch is screened for potential metallic contaminants before it can move forward. This is followed by a final visual and lot inspection, where inspectors verify seal integrity, dimensions, appearance, and packaging accuracy prior to shipment.

Together, these steps create a layered safety system where every batch passes through multiple checkpoints—each designed to catch issues, like metal contaminants, early on in production lines and protect the end consumer. Throughout the workflow, CarePac’s QA and PCQI-certified staff maintain rigorous traceability and documentation, ensuring full accountability and compliance with food-safety expectations.

How Metal Detection Supports Regulatory Compliance

Though establishing a metal detection system is not required for food manufacturers for FSMA, HACCP, or GMP compliance, the oversight ensures that preventive control measures like this meet FDA expectations. This added layer of scrutiny reinforces CarePac’s commitment to going beyond baseline requirements and adopting practices that actively reduce contamination risk. It also provides customers with greater confidence that their packaging partners are aligned with modern food-safety standards and are doing their best to avoid metal contaminants. This proactive step helps our customers demonstrate supplier verification and safety assurance during audits, supporting smoother compliance reviews and strengthening their overall food-safety programs.

The Value to CarePac Customers Involved in the Food Production Process

Our proactive approach to establishing a metal detection system for packaging adds values to brands and co-packers who depend on reliable packaging. Benefits of these detection systems include reduced risk of shipping a contaminated product, stronger audit readiness, improved consumer confidence, and supply chain continuity and fewer product rejections. At CarePac, we only have one focus: helping your business stay compliant, efficient, and trusted within the food industry.

Partner With a High Performance Packaging Supplier That Prioritizes Safety

CarePac’s multi-layered quality control system — including VOC testing, metal detection, PCQI oversight, and full FSMA/HACCP alignment — is engineered to give you confidence in every order. These safeguards play a crucial role in product safety, reduce risk, and strengthen supply chain reliability from the moment materials enter our facility to the moment finished goods ship out.

If you want packaging backed by rigorous controls and transparent documentation, contact CarePac. Our team is ready to walk you through our QC process and show how our systems can support your safety, compliance, and operational goals.

FAQs About Metal Detection in Packaging for Food Products

Lets Get Started

Made In

The USA

Full Pouch

Customization