No products in the cart.

Inside CarePac’s New Degassing Machine: Fresher Flexible Packaging Starts Here

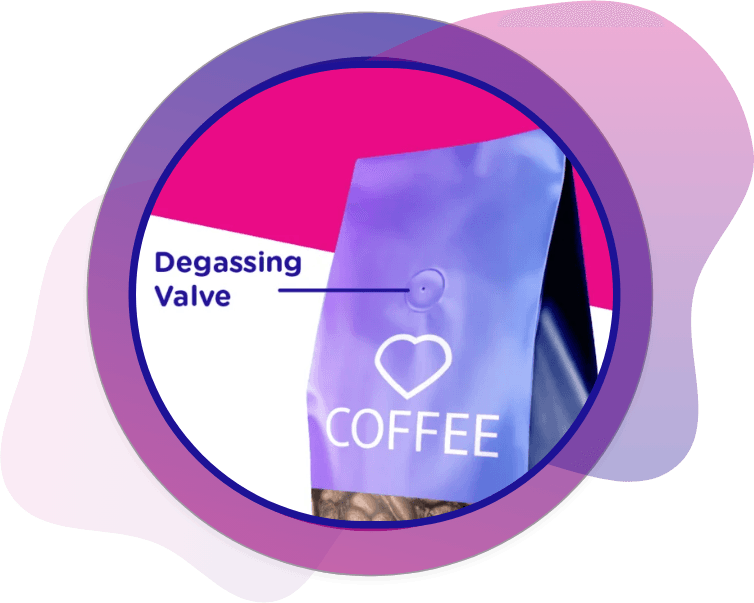

What Is a Degassing Valve — and Why It Matters

A degassing valve, also called a one-way degassing valve, is a small, specialized valve used in flexible packaging solutions that release gases. This one-way vent integrates into your packaging and allows gas to escape while preventing outside air, dust, moisture, or bacteria from entering the packaging. It's especially popular in coffee packaging because coffee, especially beans with natural oils, continues to release gases after it goes through the packaging process. These gases build up pressure inside the sealed packaging, and if the gas isn't released through valves in the lid it can cause the package to burst.

Degassing valves are critical for coffee quality, pouch integrity, and customer satisfaction. Here's more info about the impact degassing valves have on product quality and customer happiness:

Coffee freshness: Degassing valves prevent the build-up of excess carbon dioxide or days or even weeks after packaging. It also keeps oxygen out of the package. Both of these can help pre-oiled, powder, or ground coffee retain its rich aroma and strong flavors.

Maintaining pouch integrity: Most coffee drinkers want to keep their coffee in the vertical packaging it came in. Imagine how upset they would be if the coffee packaging didn't have a degassing valve and the package exploded after just a few days in storage?

Enhancing customer satisfaction: Since degassing valves work to keep the product fresh and the packaging intact, they help ensure that customers receive a high-quality product that retains its smell and flavor for a long time. And happy customers = repeat customers.

With the right packaging partner, these degassing valves can be seamlessly integrated into your coffee packaging, helping to keep oxygen and moisture out of your pre-oiled coffee beans.

Common Issues with One-Way Degassing Valve Applicators

When it comes to applying degassing valves to coffee packaging, there are several common issues that can cause the one-way degassing valves to operate incorrectly or not at all.

Misaligned valve application: If the valves aren't aligned correctly on the bag, the integrity of the seal can be impacted. This can cause leaking, reduced valve efficiency, and compromised sealing performance, among other issues.

Inconsistent adhesion: In this case, valves don't adhere properly to the bag film, resulting in detachment or leaks. These leaks can lead to product loss from degradation, compromised seal integrity, and reduced resistance to chemicals and high temperatures.

Poor valve placement or incompatible film: When the valves aren't compatible with the film, functional issues such as incomplete valve closure, leakage, reduced efficiency, and premature wear can occur.

Labor bottlenecks: If the valves are placed manually, this can lead to slower production rates and increased labor costs. Manual valve application is extremely time-consuming, so finding an automated way to add one-way degassing valves is key.

Issues with semi-automatic valve application machines: Issues with valve application machines can also occur, such as issues with power indicators, clogged filters, and maintaining consistent fill line volumes.

Introducing CarePac’s Degassing Machines for Flexible Packaging

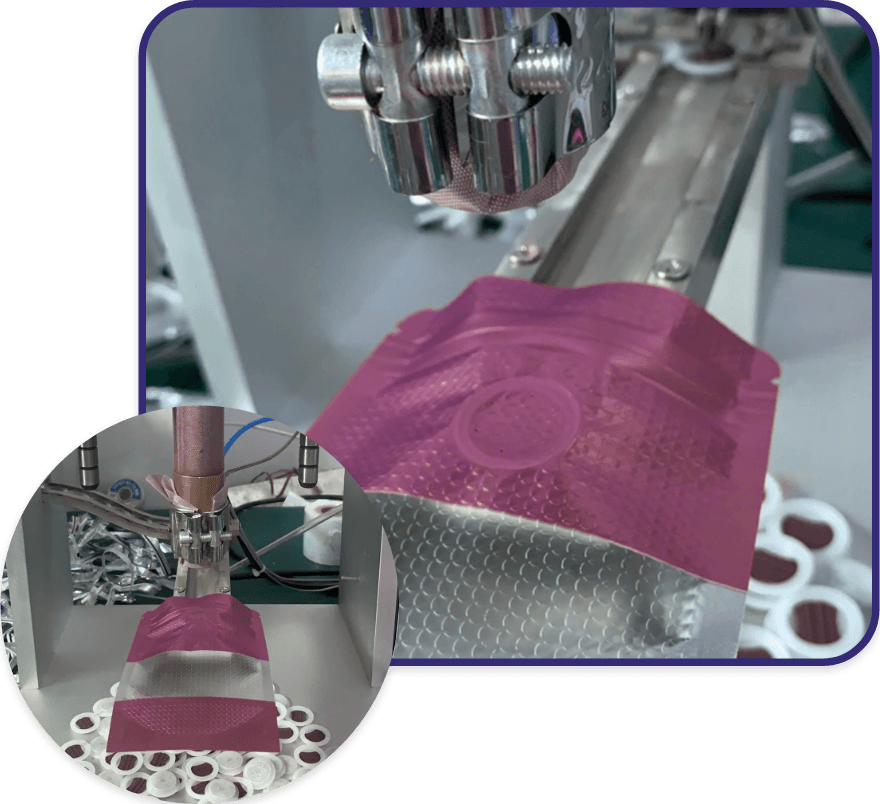

If you're concerned about the packaging machinery your current provider uses running into any of the above degassing valve issues, consider outsourcing your coffee packaging needs to a company with plenty of valve applicator experience, like us. CarePac uses state-of-the-art JW2 degassing valve application machines. Each machine is capable of applying 1,500 one-way degassing valves per hour. Alignment of the valve is controlled by an adjustable depth gauge and laser sight control system.

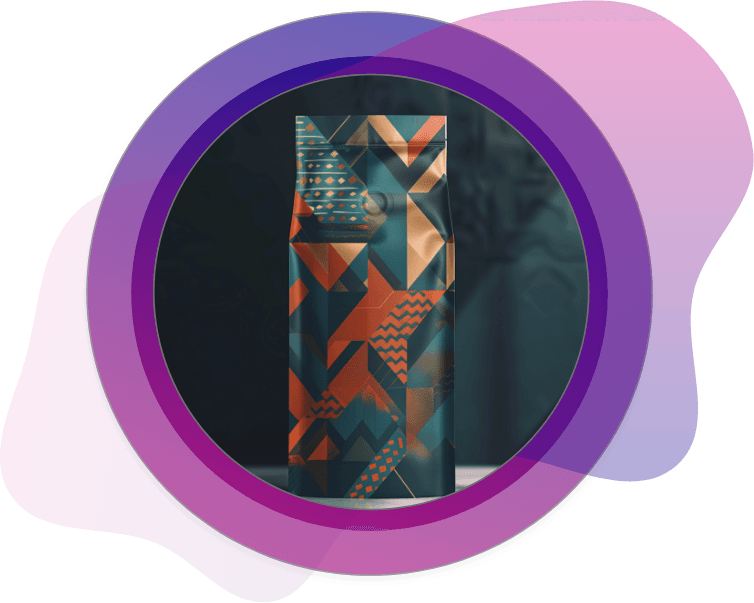

With CarePac's degassing valve machinery, you'll achieve automation speed and consistency, accurate valve placement, compatibility with all types of bag types and film materials, and efficiency gains vs. manual or older semi-automatic models. Plus, it integrates into our existing workflows so you can continue to experience the customized and cost-effective CarePac flexible packaging you're already accustomed to.

This professional and seamlessly integrated machinery allows us to process a higher number of bags per hour with higher accuracy of valve placement. Typically between 10 and 20 bags are destroyed during the heat calibration process. Our valve applicator machine is capable of using different valve molds, so we can apply one way degassing valves from different manufacturers. This way, air and carbon dioxide can escape from your packaging, regardless of its material or individual features.

What Makes CarePac a Trusted Coffee Packaging Authority

For companies seeking a flexible packaging expert with valve applicator capabilities, you can't go wrong with trusting us for your coffee packaging needs. We specialize in providing FDA-approved, food-safe packaging for a variety of industries and other markets, including coffee, snacks, and pet food. If you're looking for flexible packaging with valves, we'll keep the oxygen and moisture out of your product. Here are a few benefits to working with CarePac for your coffee packaging needs:

Responsive customer service

We pride ourselves on our customer service and strive to make the entire process as hassle-free as possible. While we use automation in the packaging plant, we maintain a human touch throughout our sales and customer service functions.

Low MOQs

With CarePac, you won't be tied to a huge minimum order volume. We offer low MOQs so businesses of all sizes can get started with customized products. For even faster turnaround, consider CarePac Express, which offers digitally printed pouches with MOQs as low as 100 bags.

R&D capabilities

We love pushing the needle on all things packaging, and one of the benefits of working with us is that we use our years of research and development to continuously improve our packaging. From enhancing the sealing capabilities of our bags to designing freshness systems, we'll make sure you're supplied with the best bags technology can offer.

Is Your Packaging Losing Freshness? Let’s Fix That.

If your coffee is being exposed to air and losing freshness, it's time to draw the line and talk to professionals about your issues. Our helpful sales team is on hand to create the customized coffee packaging you've always dreamed of. We'll integrate with your current processes and will always be available to answer questions and support your packaging goals.

Contact us today to learn more about our new degassing machine or request a quote today!

Let's Get Started

Made In

The USA

Full Pouch

Customization