No products in the cart.

What Is the Food Safety Modernization Act (FSMA) and Why It Matters

Overview of the Food Safety Modernization Act

The Food Safety Modernization Act (FSMA) was enacted by Congress in 2011 in response to a growing number of foodborne illness outbreaks and the increasing complexity of the global food supply system. The Food Safety Modernization Act gives the Food and Drug Administration the authority to regulate the food industry and implement preventing controls, including controls for preventing intentional adulteration of food products.

The goal of these federal regulations is to improve food safety, prevent contamination, and make the food system safer for both humans and animals. One of the biggest impacts the FSMA had on food safety standards at the time is that it focused on preventing contamination instead of simply reacting to it, effectively enhancing public health protection. Through the act, the FDA has expanded authority over food facilities, farms, and imported foods, including food producers, food production facilities, and food businesses of all sizes throughout the United States.

Why the FSMA Is Important for Food Safety Standards

The Food Safety Modernization Act is important for food safety standards because it shifts the focus from reacting to foodborne illness to preventing it through a proactive approach and a specific set of safety regulations. It focuses on prevention over reaction, proactive risk management, stronger regulatory oversight, accountability across the supply chain, implementing standards for imported foods, and also focuses on food defense. In the next section we'll go over each of the seven key rules / focus areas of the FSMA that businesses in the food industry must comply with.

Key FSMA Rules and Their Focus Areas

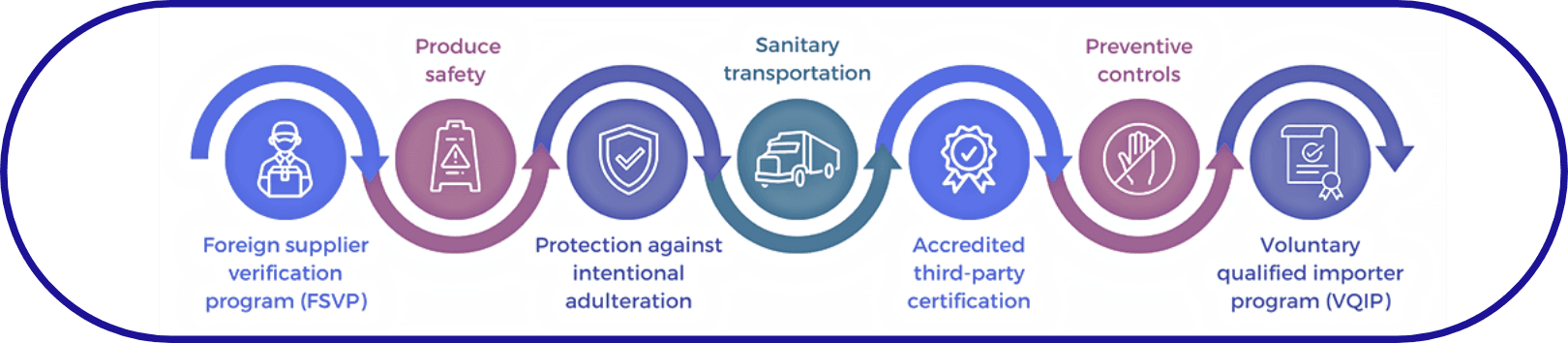

Under the Food Safety Modernization Act, there are seven key rules that food safety agencies expect food facilities to meet, most of which are preventive control standards. Here are the key FSMA food safety standards:

Preventative Controls for Human Food- Food facilities registered with the FDA must implement a written plan that outlines hazards and appropriate preventative controls they will take.

Foreign Supplier Verification Program- Importers must verify that the vendors that are part of their global supply chain comply with FDA regulations, even if they are foreign food facilities. Imported foods are not exempt from these preventive controls.

Preventative Controls for Animal Food- Animal food companies registered with the FDA must do the same as above, except tailored to the animal food they produce.

Third-Party Certification- Accredited third party certification bodies administer voluntary consultations and regulatory audits to help companies prepare for audits or achieve certifications.

Produce Safety- This establishes minimum standards for growing, harvesting, packing, and storing produce, including at farmers markets.

Food Defense- This aims to avoid intentional adulteration of food. Food facilities must assess their contamination vulnerabilities, put together a hazard analysis, and document a mitigation strategy for each vulnerability outlined in the hazard analysis.

Sanitary Transportation- Requires food businesses that transport food, including shippers, receivers, loaders, and carriers to comply with specific requirements outlined by the Food and Drug Administration and other government agencies.

Preventive Controls for Human and Animal Food

Preventative controls for human and animal food involve monitoring, keeping records, and performing hazard analysis in reference to both human and animal food. For human food, this means food facilities must implement comprehensive food safety plans that address hazards specific to their operation. This includes implementing specific controls that focus on allergen and sanitation controls, as required by the FDA's rule for Preventive Controls for Human Food.

For animal food, the specific rules and requirements differ from those for human food. The underlying principle of preventing hazards for animal food remains the same, but the detailed regulatory requirements are tailored to animal food.

Produce Safety Rule and Farm-Level Practices

Through the Produce Safety Rule, the FSMA extends to farms throughout the United States. The FSMA conducts food safety audits to verify that farms have appropriate preventive controls in place. The goal of conducting food safety audits is to ensure that agricultural and food processing facilities focus on training, water testing, hygiene, and safe agricultural practices that will help protect the food supply chain. This focus on farm-level practices impacts both small and large producers and aims to significantly minimize foodborne illness and food safety risks that may occur at the growing and production level.

The Foreign Supplier Verification Program (FSVP)

Some mistakenly believe that the FSMA only focuses on food grown or produced in the United States, but foreign food facilities comply with it as well. Under the Foreign Supplier Verification Program, all qualified importers must verify that their suppliers meet FSMA rules. The importer is responsible for inspections, record keeping, and certification, and the goal of the FSVP is to ensure that all food imported into the United States meets the qualifications and regulations outlined by the FSMA.

How This Food Safety Law Impacts the Packaging Industry

Packaging plays a critical role in the food safety ecosystem—a fact recognized within FSMA’s preventive approach to keeping food safe from contamination. At CarePac, we design and manufacture packaging that supports these same goals. Our food-grade materials, controlled manufacturing environment, and robust QC processes—including VOC testing—help ensure every pouch, roll, or film aligns with FDA and FSMA expectations for safety and compliance.

Whether you’re building a preventive control program or preparing for an audit, CarePac’s regulatory understanding and quick turnaround make it easy to stay compliant without slowing your operations. Contact us today to discuss FSMA-aligned packaging or request QA documentation to support your food safety program.

Staying Ahead with FSMA Guidance and Updates

FSMA guidance continues to evolve as the FDA refines its approach to preventive controls, traceability, and food-contact safety. Manufacturers and food facilities should stay informed by following the latest updates, training programs, and best practices published by the FDA and industry partners. For ongoing reference, consider bookmarking the FDA’s official FSMA resource page.

Talk to Our Packaging Experts

At CarePac, we understand the importance of packaging that not only protects your food product but also aligns with FSMA and retailer quality standards. Our team combines deep regulatory knowledge with fast, reliable turnaround times—helping you stay compliant with accredited third party certification bodies without slowing production. Whether you need QA documentation, VOC data, or packaging materials that are fully compliant with federal regulations, we’re ready to support your food safety program.

Contact us today to discuss your compliance needs or request supporting documentation.

FAQs About the Food Safety Modernization Act

Here are some common questions we receive about the Food Safety Modernization Act.

Lets Get Started

Made In

The USA

Full Pouch

Customization